A method of using degradable plastic film to prevent leakage of slurry

A technology of plastic film and anti-leakage slurry, which is used in the preparation of building components on site, the connection of formwork/formwork/work frame, construction, etc. Waste and other problems, to prevent the leakage of slurry at the joints or the bottom side, improve the quality of the building, and improve the pressure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

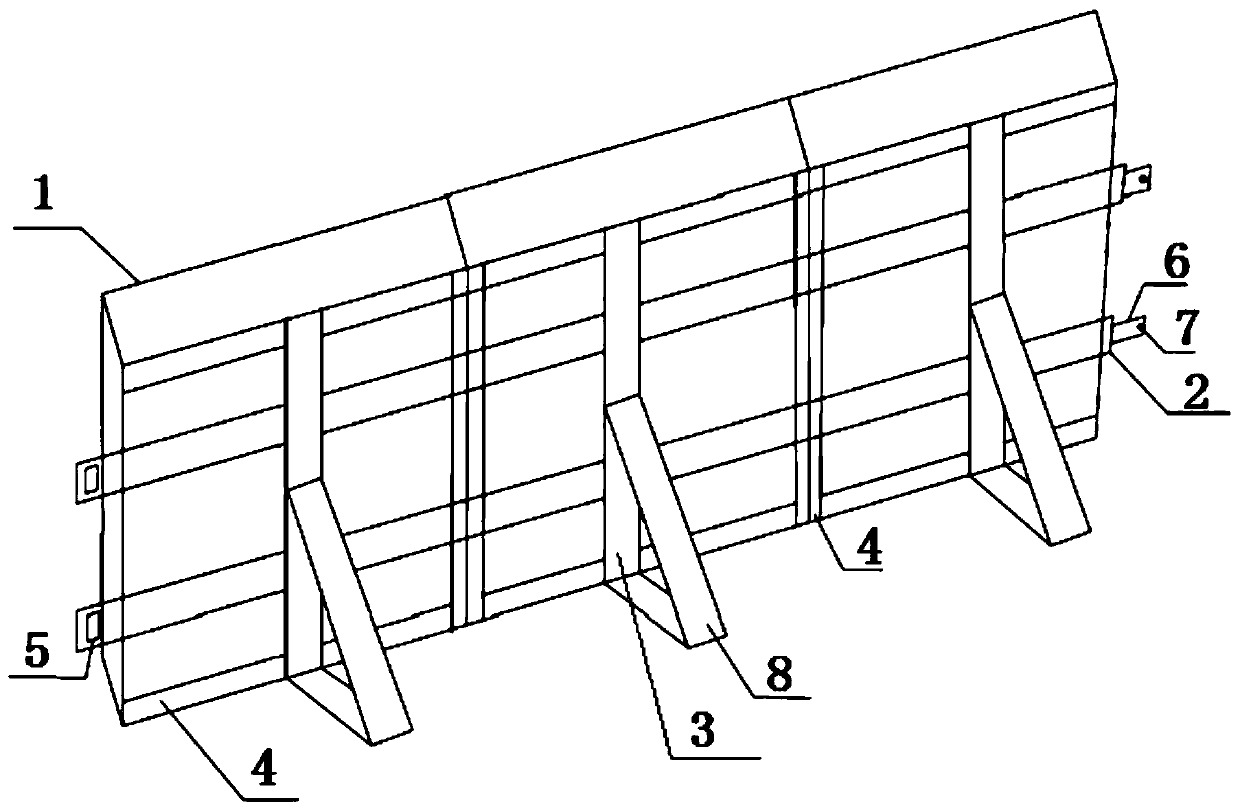

[0044] A method of utilizing a degradable plastic film to prevent slurry leakage, comprising the steps of:

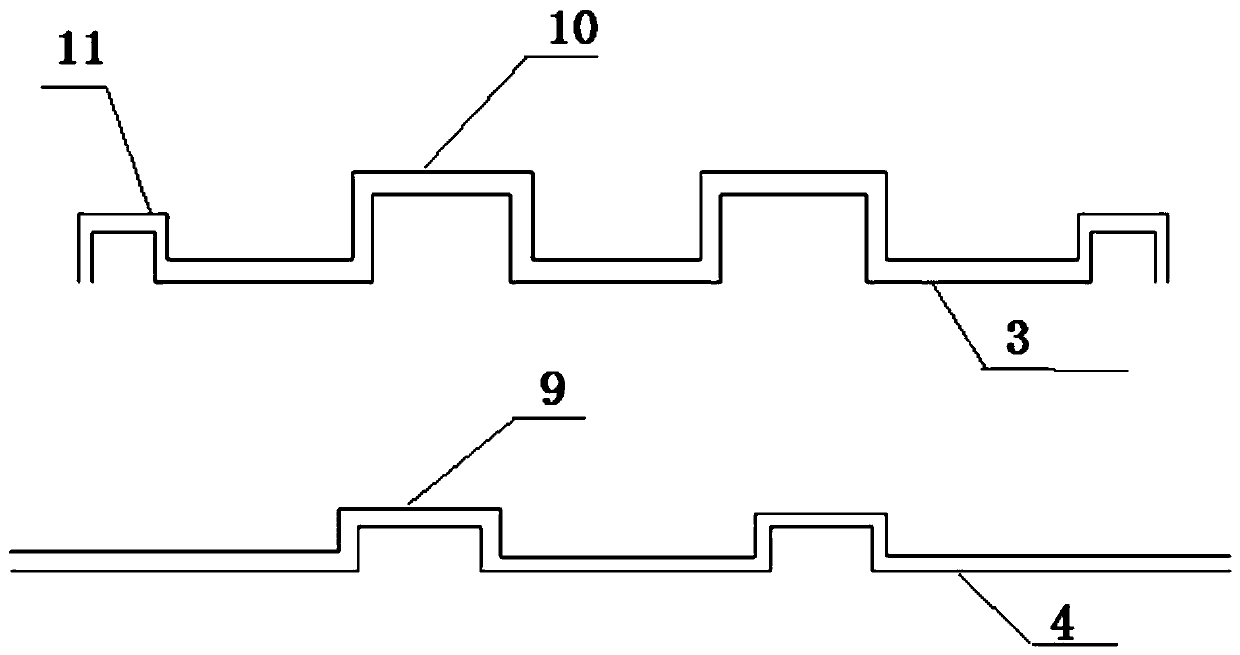

[0045] 1) Apply an appropriate amount of edible oil on the template 1, spread the plastic film on one side of the template, and each side of the plastic is wider than a part of the template;

[0046] 2) Wrap the wide plastic around the template 1 in step 1) with a crossbar, and bond the contact surface with the template with an adhesive;

[0047] 3) The template 1 obtained in step 2) is placed, and the template 1 is fixed horizontally and vertically by using the horizontal fixing rod 2 and the vertical fixing rod 3. 4 fixing, the top of the vertical fixing rod 3 is fixed with the cross bar 4 on the template top;

[0048] 4) Concrete is poured into the space enclosed by formwork 1;

[0049] 5) After the concrete on the wall is solidified, the horizontal fixing rod 2 and the vertical fixing rod 3 on the outer surface of the formwork 1 are disassembled, and the formwork ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com