Temperature detection device for high-temperature and high-pressure environment and preparation method of device

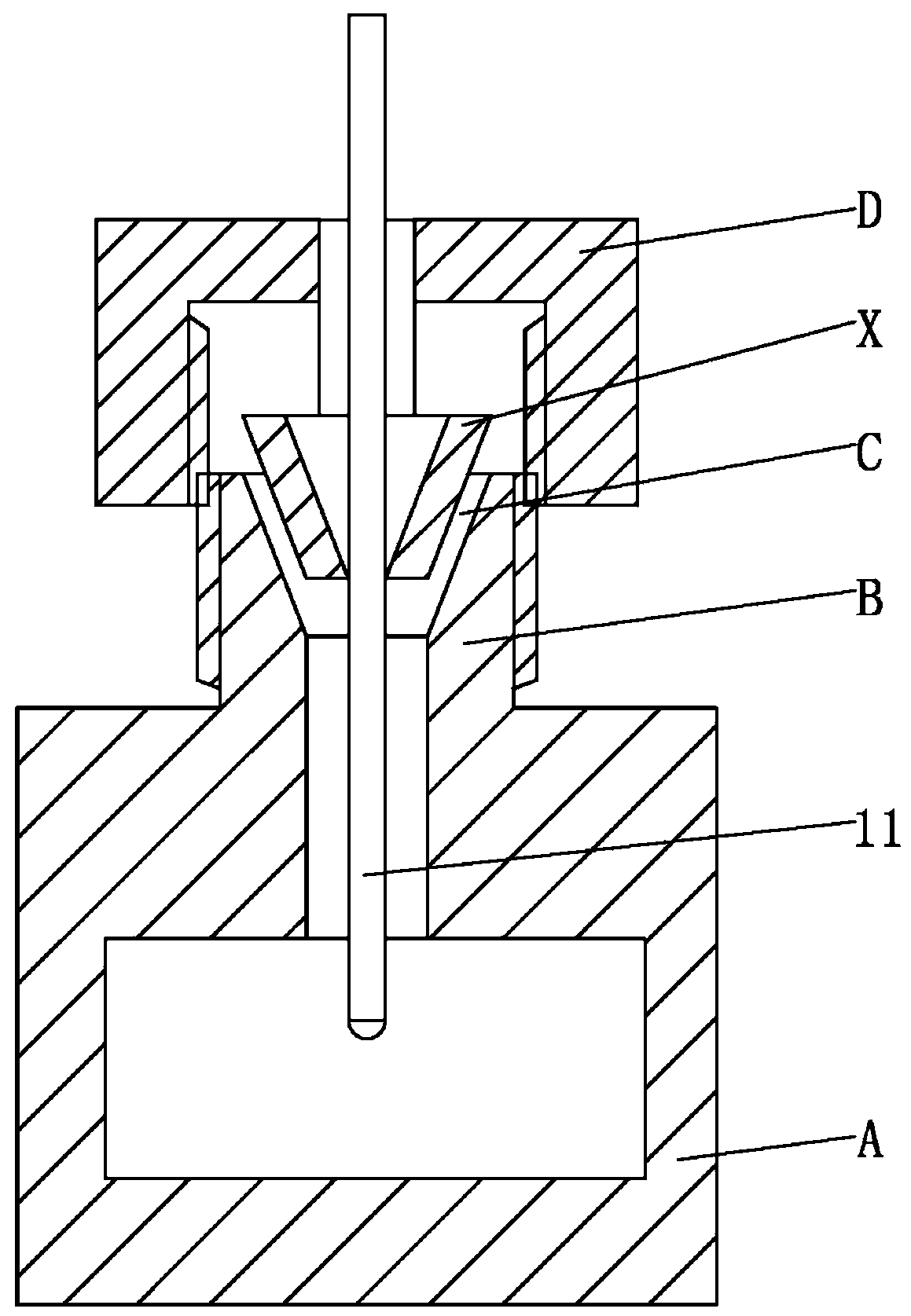

A temperature detection device, high temperature and high pressure technology, applied in measuring devices, thermometer parts, thermometers, etc., can solve the problems of easy breakage of the sealing surface, leakage accidents, damage to the shell of the temperature sensor 11, etc., to avoid breakage and improve response. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

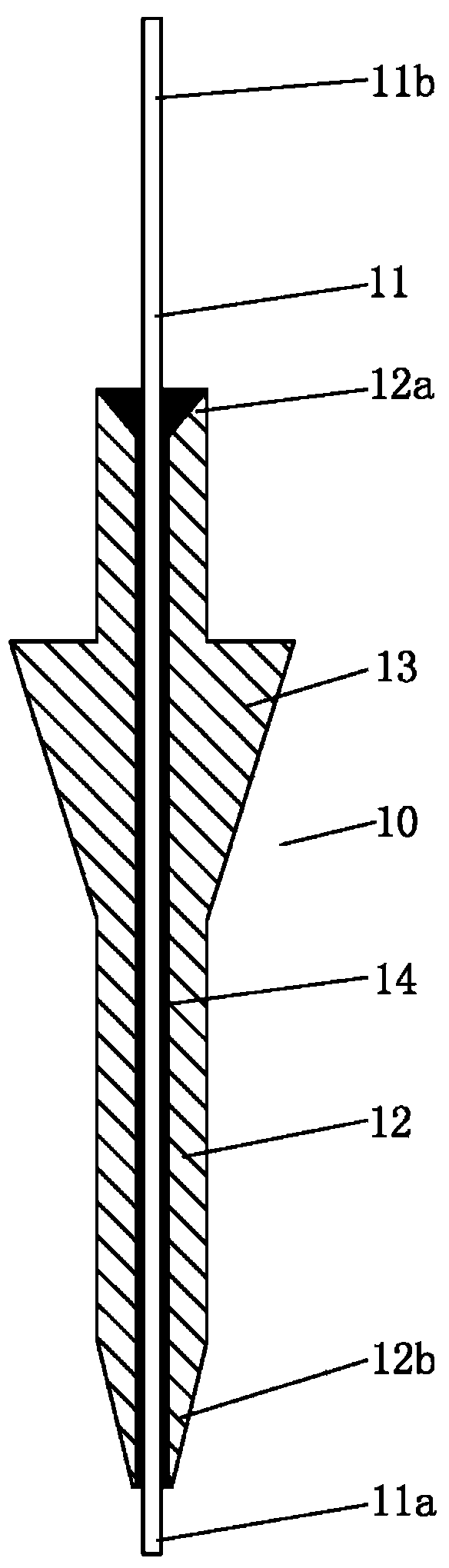

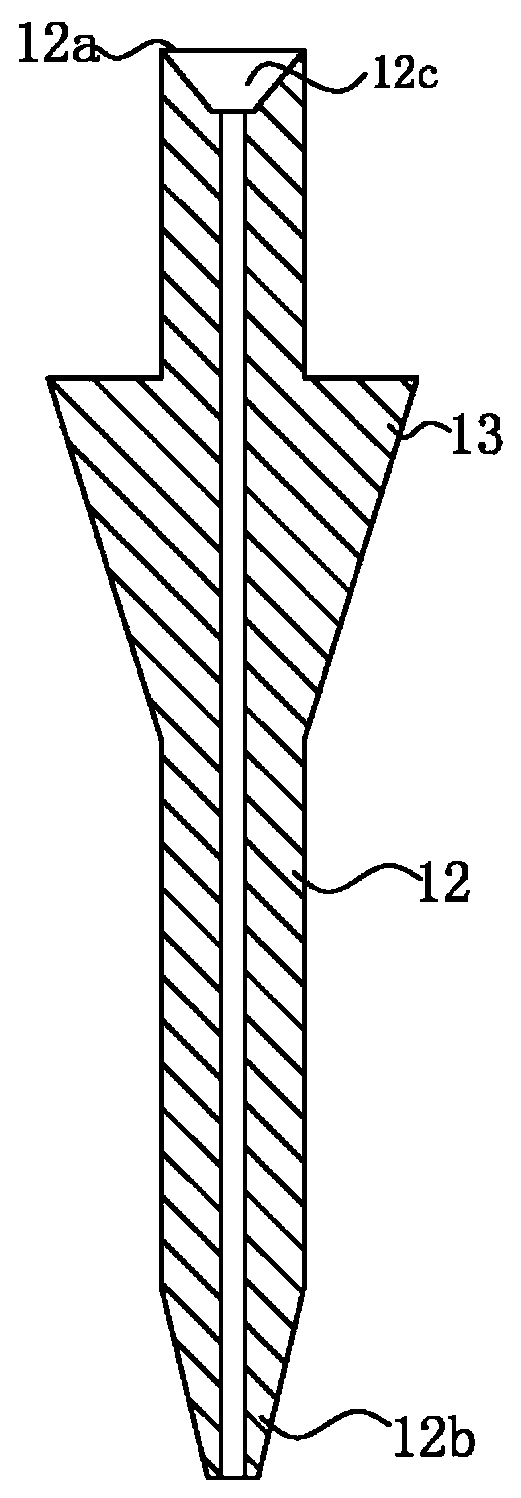

[0031] The preparation method of the temperature detection device 10 is prepared through the following process:

[0032] The temperature sensor 11 is an armored thermocouple temperature sensor with an outer diameter of 1.98-2.00 mm, and the outer shell material of the temperature sensor 11 is a superalloy material Incoloy800H (UNS N08810). The bushing is machined from high temperature alloy material Incoloy 800H (UNS N08810), and the diameter of the inner hole of the bushing body 12 is 2.00~2.02mm.

[0033]Before the temperature sensor 11 passes through the bushing body 12, the temperature sensor is first rinsed with a solution, and then cleaned with a cleaning agent and dried. The rinsing process for the temperature sensor 11 is as follows: first rinse with 10% HCl solution for 3 minutes, and then rinse with 15% NaOH solution for 20 minutes. By rinsing, the chemical layer and oil film on the surface of the temperature sensor 11 are removed, so that the temperature sensor 11 ...

Embodiment 2

[0042] The preparation method of the temperature detection device 10 is prepared through the following process:

[0043] Before the temperature sensor 11 passes through the bushing body 12, the temperature sensor is first rinsed with a solution, and then cleaned with a cleaning agent and dried. The temperature sensor rinsing process is as follows: first use 15% HCl solution to rinse for 5 minutes, and then use 15% NaOH solution to rinse for 20 minutes. The rinsed temperature sensor 11 is cleaned by using absolute ethanol as a cleaning agent.

[0044] The temperature sensor 11 is an armored thermocouple temperature sensor, and the outer shell material of the temperature sensor 11 is a superalloy material Incoloy800H (UNS N08810). The bushing is machined from high-temperature alloy material Incoloy 800H (UNS N08810), and the diameter of the inner hole of the bushing body 12 is 1.5-1.52 mm.

[0045] The detection end 11a of the temperature sensor 11 protruding into the high tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com