Method and device suitable for measuring specific heat capacity at constant pressure of dissolved gas flow

A technology of constant pressure heat capacity and fluid ratio, applied in the direction of material thermal development, etc., can solve problems such as difficulty in maintaining constant mixed fluid components, and achieve the effect of reducing working fluid consumption and stabilizing components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

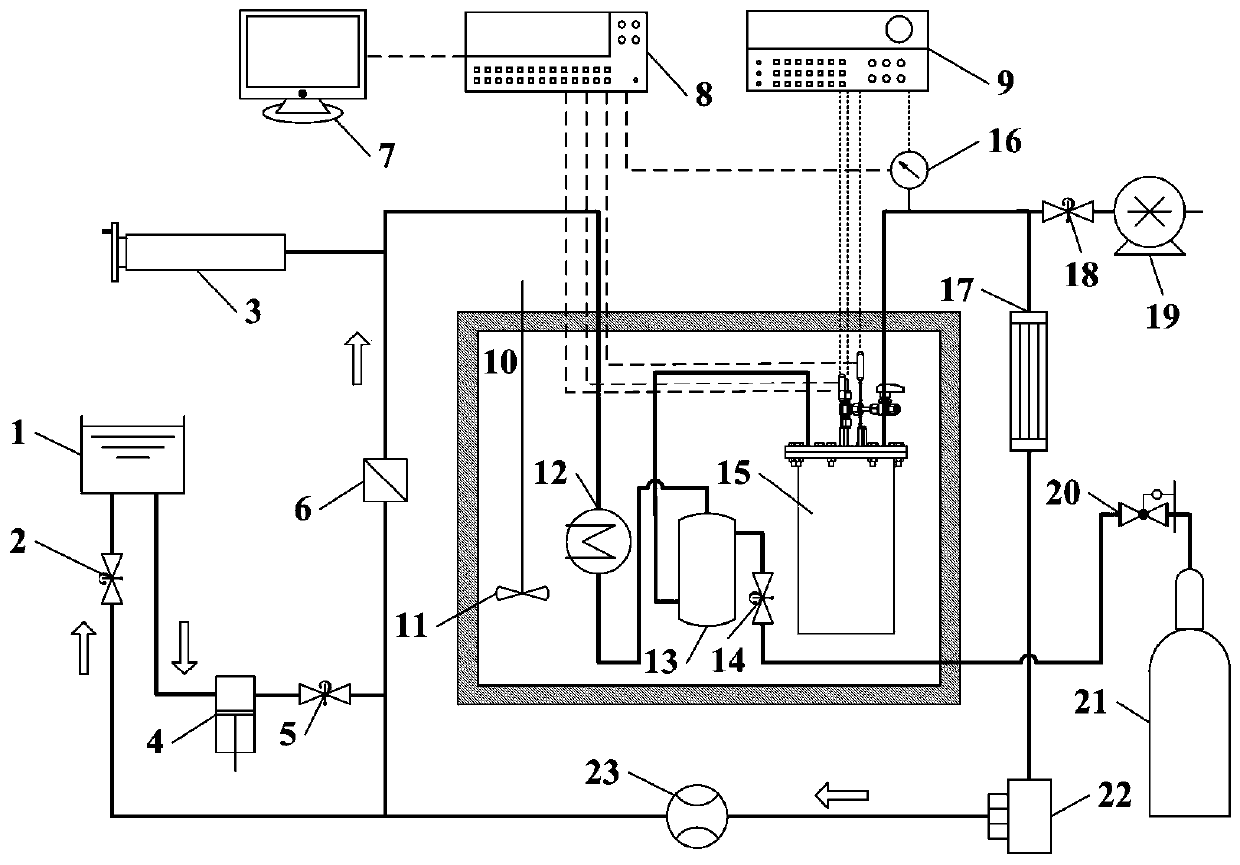

[0034] see figure 1 The device for measuring the ratio of heat capacity of dissolved gas fluid to constant pressure according to the present invention mainly includes: liquid container 1, first valve 2, pressure regulator 3, advection pump 4, second valve 5, filter valve 6, electronic computer 7. Digital multimeter 8, DC power supply 9, constant temperature tank 10, circulation fan blade 11, preheater 12, mixing chamber 13, third valve 14, calorimeter 15, pressure transmitter 16, condenser 17, fourth Valve 18, vacuum pump 19, pressure reducing valve 20, gas sample bottle 21, circulation pump 22, flow meter 23. Wherein, advection pump 4 is connected with liquid container by pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com