Method and system for managing finished products in electric energy meter finished product warehouse

A technology of warehouse management and management method, applied in the field of electric meter manufacturing, can solve the problems of restricting the development of enterprises, chaotic placement of finished products in the workshop, and high labor intensity, achieving the optimization of manpower, the maximum utilization of warehouse space, and the highest degree of intelligent automation. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

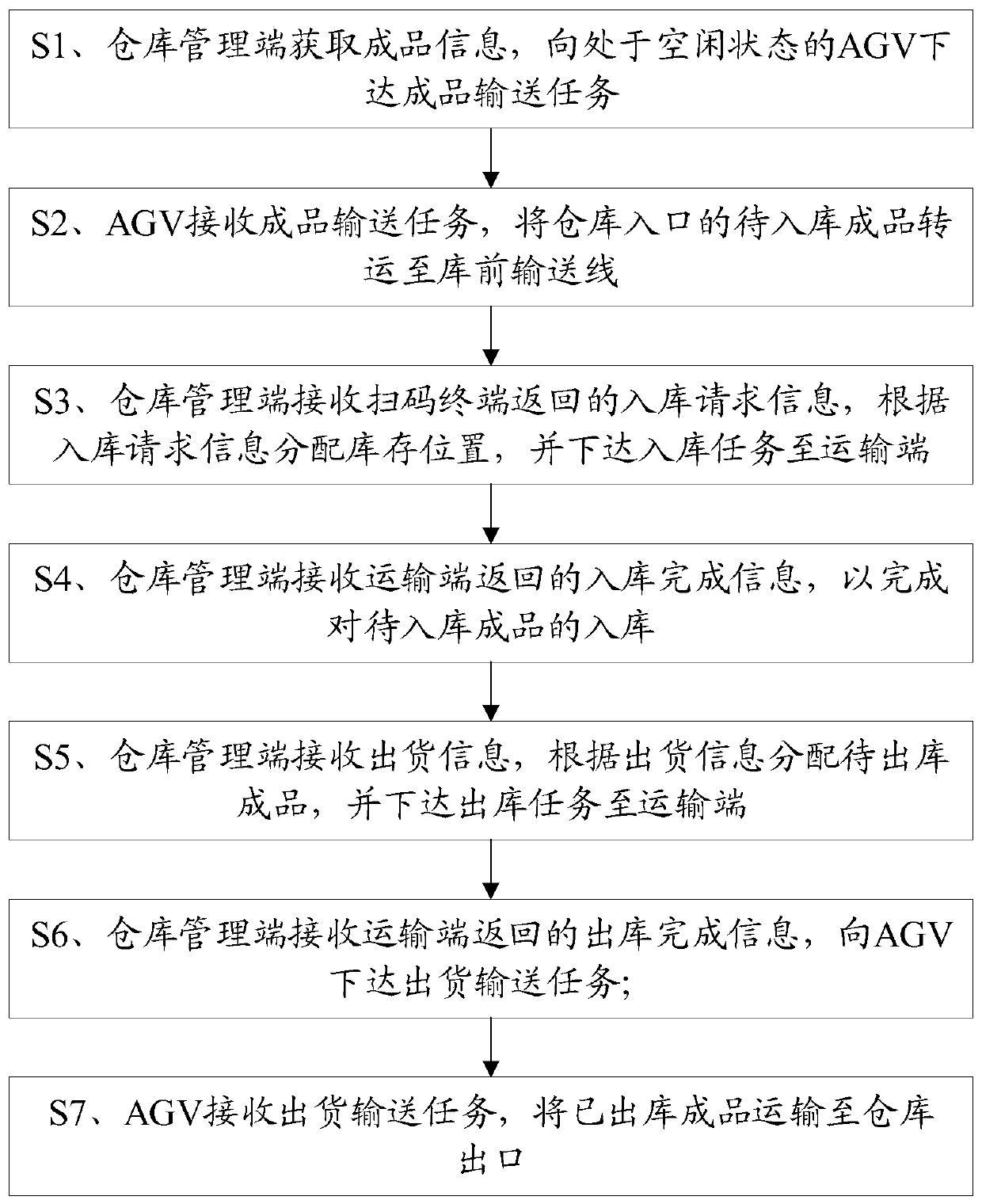

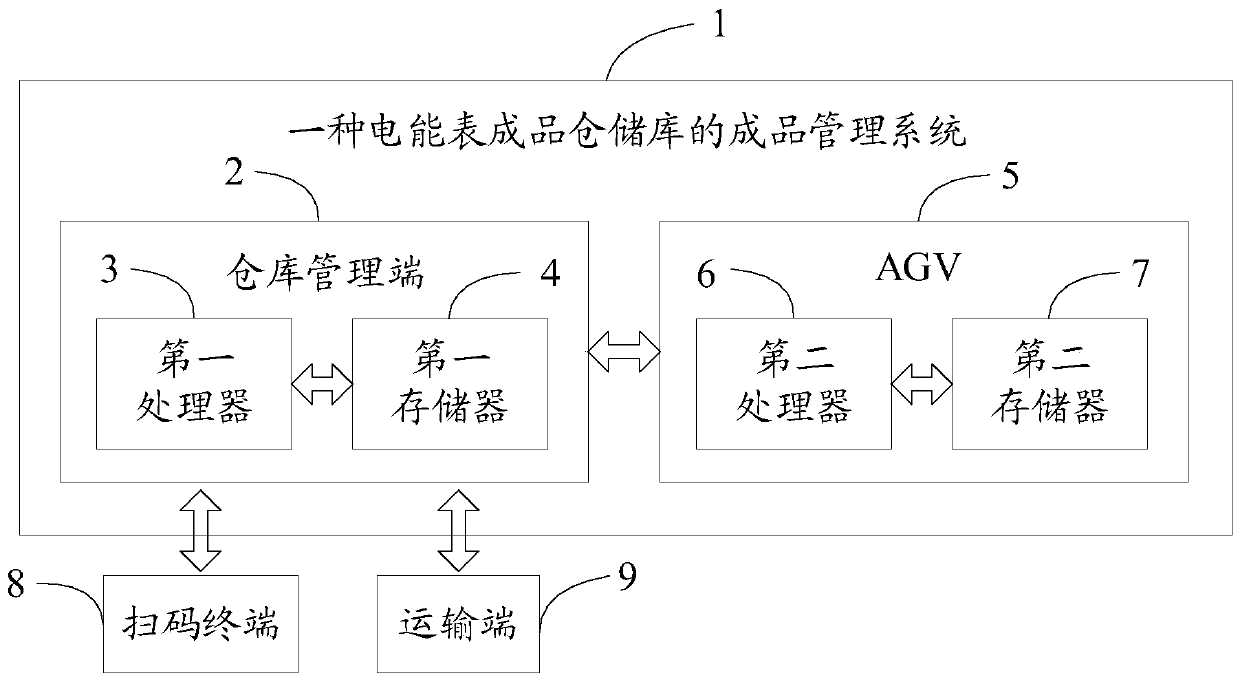

[0105] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0106] A finished product management method for a storage warehouse for finished electric energy meters, comprising the steps of:

[0107] S1. The warehouse management terminal obtains the finished product information, and sends the finished product delivery task to the idle AGV;

[0108] S2. The AGV receives the delivery task of finished products, and transfers the finished products waiting for storage at the entrance of the warehouse to the conveyor line before the warehouse;

[0109] Among them, the code scanning terminal scans the finished product code on the finished product to be stored, generates storage request information including finished product information, and sends the storage request information to the warehouse management terminal;

[0110] S3. The warehouse management terminal receives the warehousing request information returned by the code scanning terminal, allocates the invent...

Embodiment 2

[0117] Please refer to figure 1 , the second embodiment of the present invention is:

[0118] A finished product management method for a finished product warehouse of electric energy meters, on the basis of the first embodiment above, step S3 is specifically:

[0119] The warehouse management terminal receives the barcode information to be stored returned by the scanning terminal, and compares the barcode information to be stored with the finished product information recorded within the first preset storage time. If it is recorded within the first preset storage time If the first finished product information matches the barcode information to be put into storage, record and return the first finished product information to the code scanning terminal.

[0120] The warehouse management terminal receives the warehousing request information returned by the scanning terminal, and judges whether the first finished product currently stored in the first finished product storage area h...

Embodiment 3

[0121] Please refer to figure 1 , Embodiment three of the present invention is:

[0122] A method for managing finished products of electric energy meters in a warehouse for finished products. On the basis of the first embodiment above, step S1 is specifically as follows:

[0123]S11. The warehouse management terminal obtains finished product information, and obtains a list of AGVs that are in an idle state and are arranged in order from near to far according to the distance from the warehouse entrance;

[0124] S12. The warehouse management terminal plans the first AGV at the top of the AGV list to return to the first preset homing path of the warehouse entrance, and calculates the first AGV's return to the warehouse entrance according to the first preset homing path and the AGV speed. A preset homing time, judging whether other AGVs have passed the first preset homing path within the first preset homing time, if no other AGVs have passed the first preset homing path within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com