Magnetic component and manufacturing method thereof

A technology of magnetic components and magnetic components, applied in the direction of preventing/reducing unwanted electric/magnetic effects, transformer/inductor casing, transformer/inductor coil/winding/connection, etc. The molded shell cannot shield the magnetic field, high magnetic permeability and other problems, so as to achieve the effect of high current and suitable for batch automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

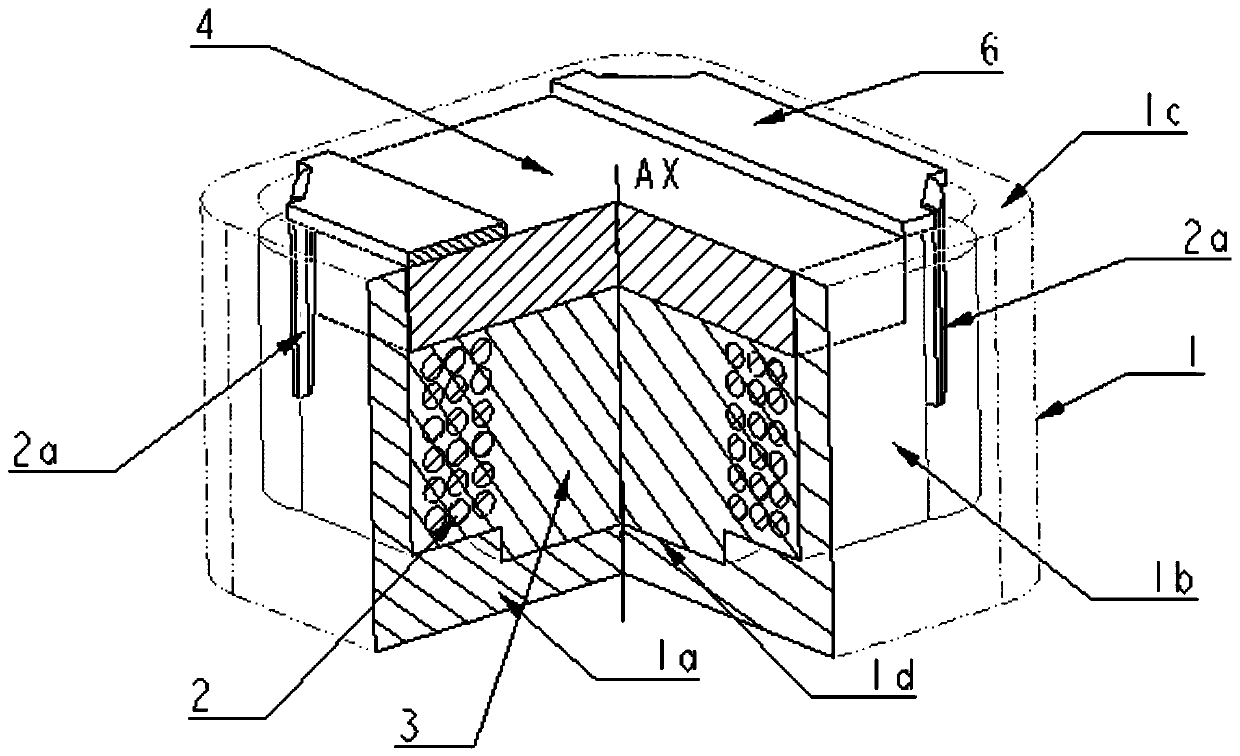

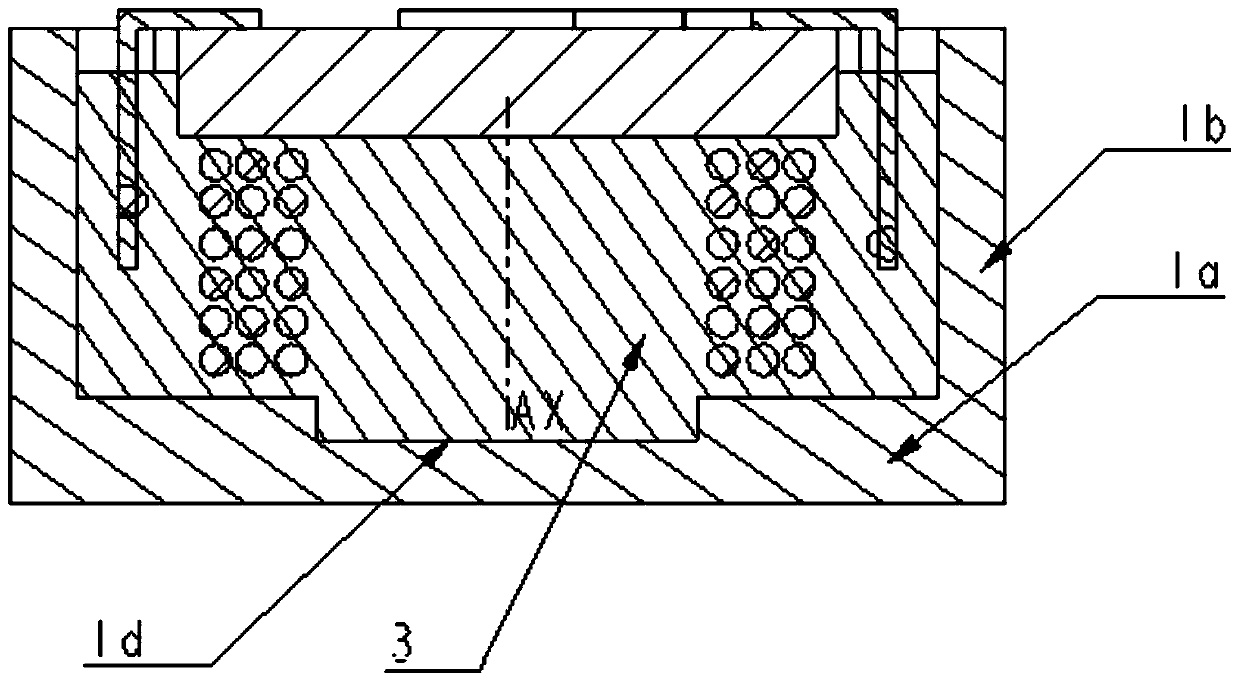

[0060] The surface mount magnetic component involved in this embodiment has an external dimension of 12mm×12mm×8.5mm, which belongs to the category of power inductors. Such as figure 1 Shown is a perspective cutaway view of this surface mount power inductor. It includes a soft magnetic shell 1 made of manganese zinc ferrite, the soft magnetic shell has a bottom plate 1a, a side wall 1b formed along the edge of the bottom plate and extending vertically toward the bottom plate, and an opening 1c opposite to the bottom plate, and in An accommodation space is provided in the housing; an air-core coil 2 is placed in the accommodation space; the air-core coil 2 has a winding helical axis AX, and the air-core coil 2 is placed perpendicular to the direction of the bottom plate 1a of the soft ferrite housing according to the helical axis AX. The inner wall surface of the magnetic housing 1 perpendicular to the screw axis AX (in this embodiment, the inner side of the bottom plate 1a) i...

Embodiment 2

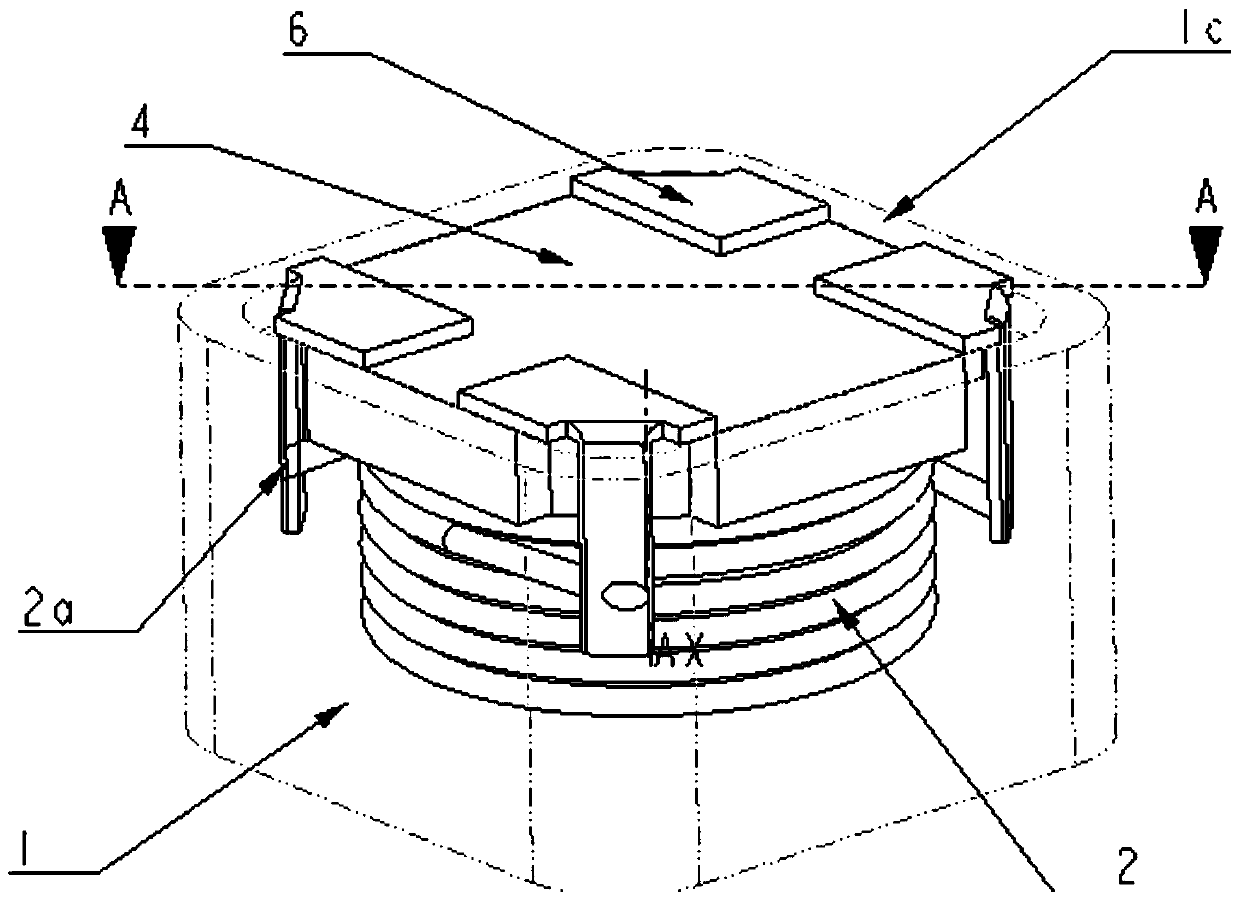

[0063] This embodiment relates to a surface-mounted magnetic component, which has double windings and can be used as a coupling inductor, a common-mode inductor, an isolation transformer, etc., and its external dimensions are 12mm×12mm×8.5mm. Figure 2(a) is a perspective view of the magnetic element, and Figure 2(b) is a cross-sectional view along AA'. It includes a soft magnetic shell 1 made of nickel-zinc ferrite with a magnetic permeability of 400; the soft magnetic shell has a bottom plate 1a, a side wall 1b formed along the edge of the bottom plate and extending vertically toward the bottom plate, And the opening 1c opposite to the bottom plate, and provide an accommodation space in the casing; two air-core coils 2 are placed in the accommodation space; the air-core coil 2 has a winding helical axis AX, and the air-core coil 2 is perpendicular to the soft coil according to the helical axis AX The ferrite shell is placed in the direction of the bottom plate 1a, and a reces...

Embodiment 3

[0065] This embodiment relates to a plug-in magnetic component and its manufacturing method, which can be used as a PFC inductor, reactor, etc., and is widely used in the fields of industrial power supply and vehicle electronic control. Such as image 3 As shown, from left to right and from top to bottom is the manufacturing process of the plug-in magnetic component. First, a soft magnetic shell 1 is provided, made of manganese zinc ferrite, the magnetic permeability of the manganese zinc ferrite material is greater than 2000, and the saturation magnetic flux density at room temperature is greater than 0.5T; the soft magnetic shell has a bottom plate 1a, along the edge of the bottom plate Form and extend the side wall 1b perpendicular to the bottom plate, and the opening 1c opposite to the bottom plate, and provide an accommodation space in the casing; an air-core coil 2 is placed in the accommodation space, and the air-core coil is vertically wound with a flat copper wire Ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation flux density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com