Heat transfer fluids and methods for preventing corrosion in heat transfer systems

A technology of heat transfer fluid and corrosion inhibitor, applied in the field of heat transfer fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

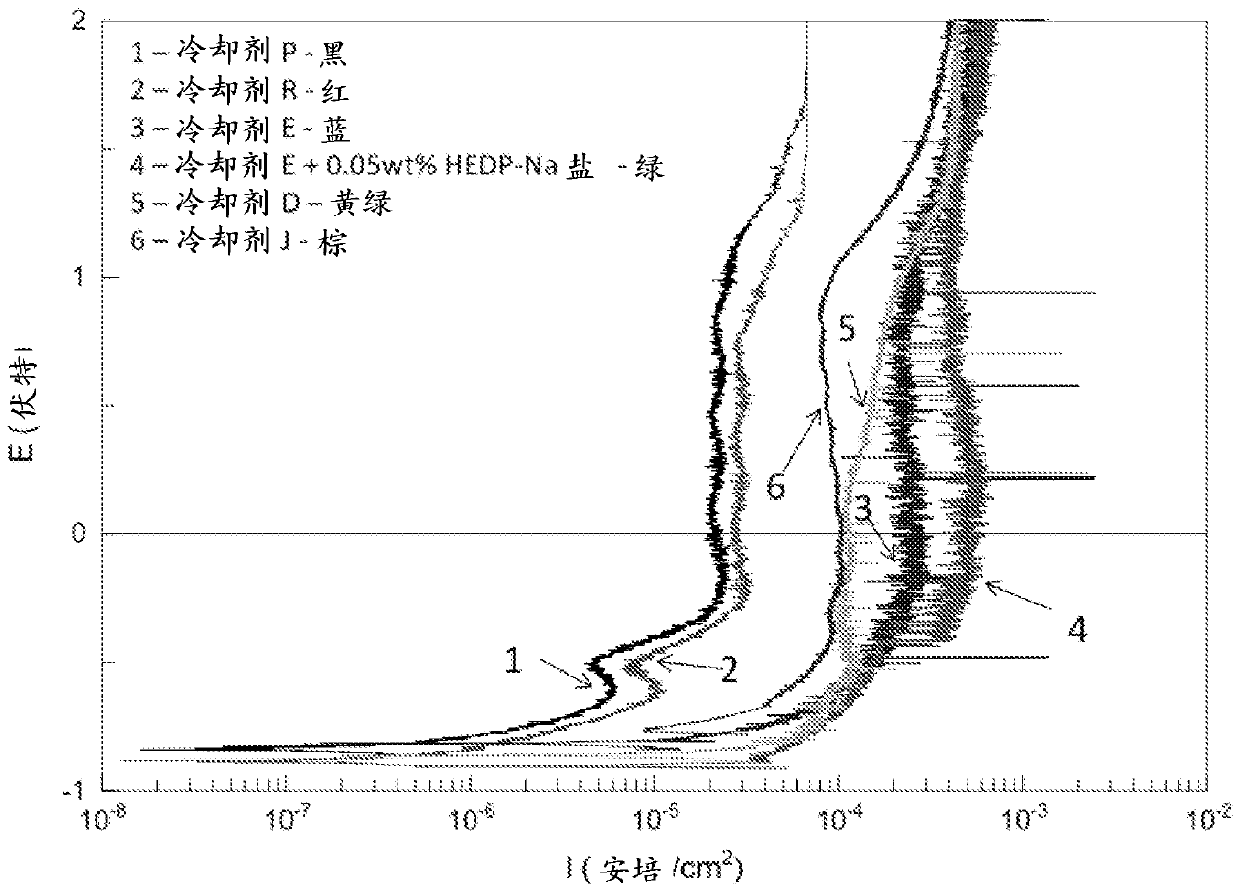

[0014] To ensure a long service life and function as designed, metal components used in automotive cooling systems must be protected from corrosion by engine coolant. Additionally, engine coolant should be compatible with non-metals used in the cooling system such as hoses, gaskets and plastics. Excessive corrosion or degradation of materials used in cooling systems can lead to significant loss of material or component strength, loss of coolant from the system and subsequent failure in one or more cooling system components. All of these events can lead to engine failure. Additionally, even relatively mild corrosion can result in the formation of corrosion products that can form scale or deposits on heat transfer surfaces. These scales or deposits can greatly reduce the rate of heat transfer. The thermal conductivity of non-porous scale is about 1.04 W / mK to 3.46 W / mK at 25°C, and the thermal conductivity of sediment or porous scale may be about 0.35 W / mK at 25°C. These valu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com