Enclosure system including wire mesh and thin non-porous membrane panels

A package and panel technology, which is applied to the components, pump components, electrical components, etc. of the pumping device for elastic fluid, can solve the problems of increasing capital cost, and achieve the effect of suppressing unintentional discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

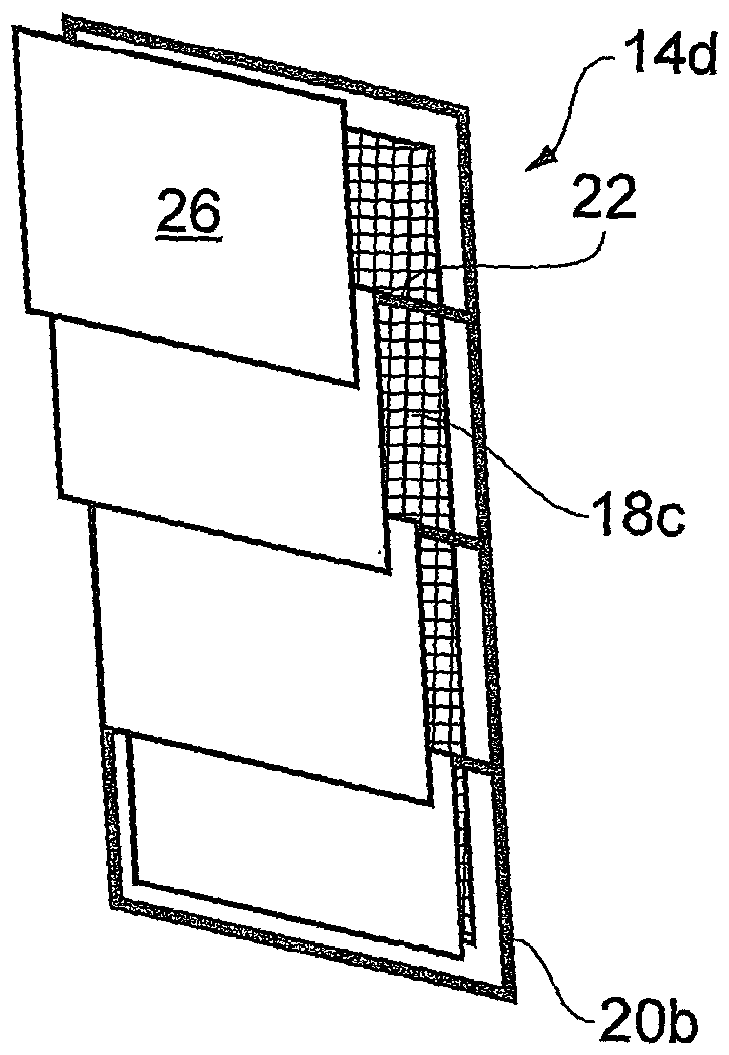

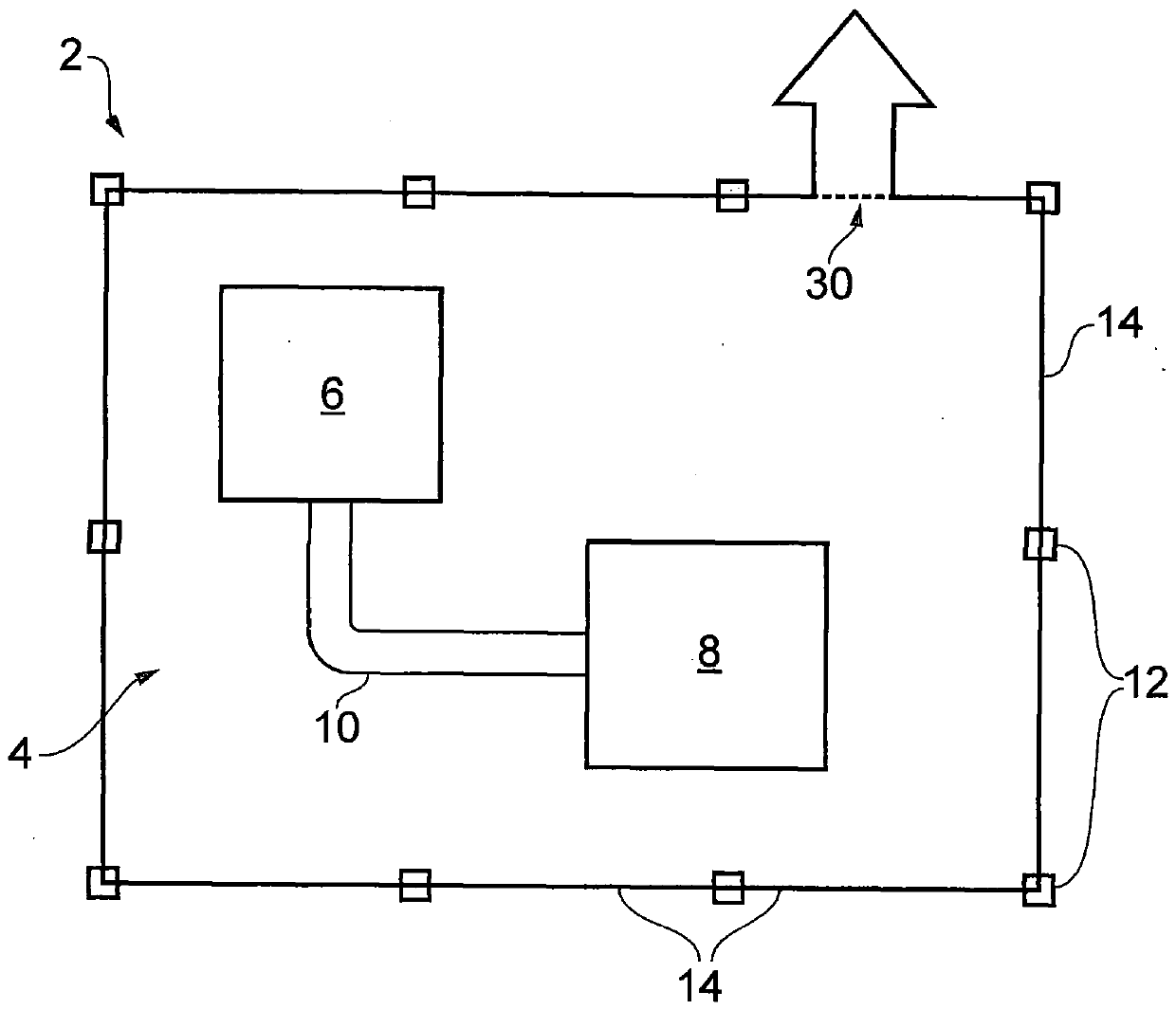

[0031] figure 1 A wrapping element system 2 according to the invention is illustrated. The enclosure system 2 is configured to enclose one or more pieces of equipment. The equipment represents a collection of equipment located downstream of a semiconductor processing chamber that, in operation, receives harsh process gases from the semiconductor processing chamber. The process gas includes unused precursor gases and by-products formed during processing within the chamber. In this example, the rear chamber equipment 4 comprises a vacuum pump 6 connected via a conduit 10 to an abatement unit 8 . One or more valves (not shown) will also be incorporated into the equipment 4 . The equipment is in fluid communication with a processing chamber (eg, an epitaxy chamber (not shown)) via another conduit or foreline (not shown).

[0032] The enclosure system 2 comprises a metal frame 12 configured to describe an outer enclosure surrounding the workspace of the back room equipment 4 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com