Low temperature formation of high quality silicon oxide films in semiconductor device manufacturing

A semiconductor, silicon oxide layer technology, applied in semiconductor/solid state device manufacturing, electrical components, gaseous chemical plating, etc., can solve problems such as film cracking, reliability problems, affecting electrical and optical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

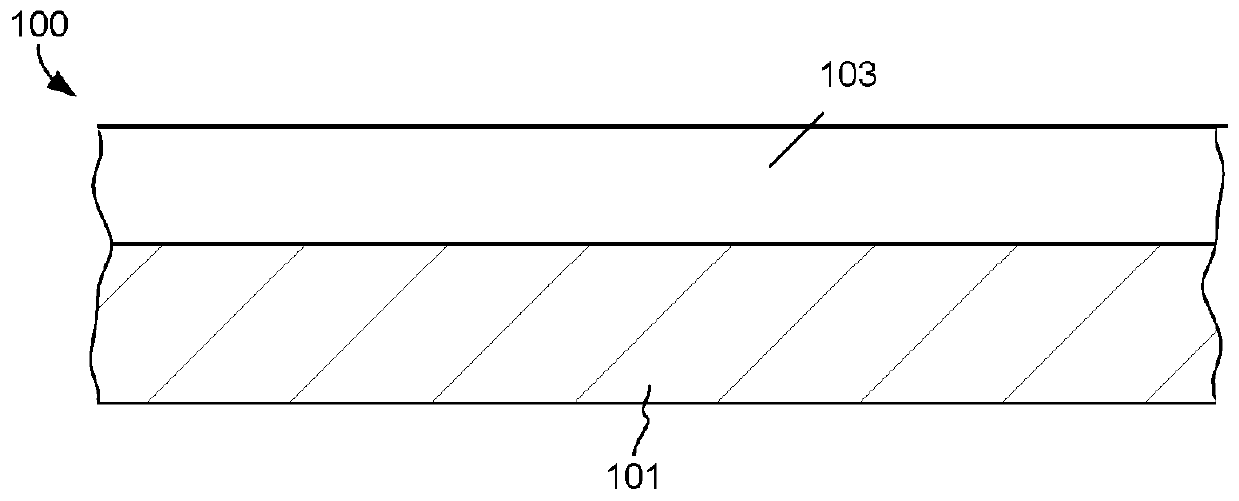

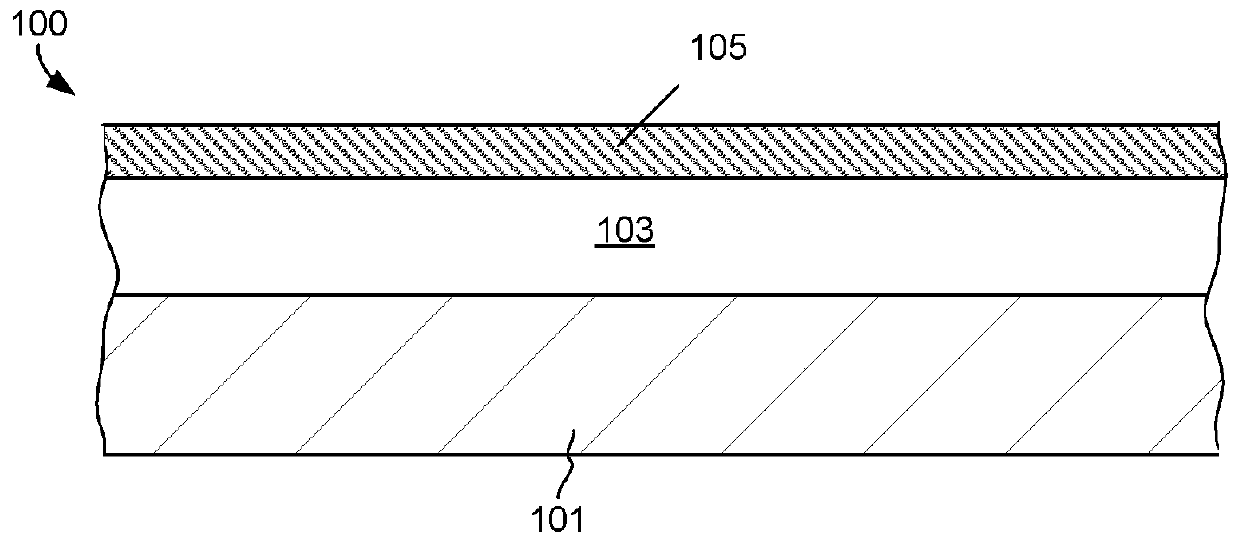

[0089] Example 1. Formation of a silicon oxide film with low stress and high density.

[0090] A number of silicon oxide films were deposited by PECVD on flat 300 mm wafers in a Vector PECVD reactor available from Lam Research Corporation, Fremont CA, at a temperature of 180° C. and a pressure of 2.5 Torr to 3.5 Torr. The process gas used during deposition consists of SiH 4 (provided at 30sccm), CO 2 (provided at 4200 sccm) and He composition. The plasma is generated in the process gas using 13.56MHz HF RF at a power level of 100-400W. Deposition proceeds for 5 seconds; then stops SiH 4 and CO 2 flow into the processing chamber while plasma and helium flows are maintained for 5 seconds to 4 and CO 2 Purge out of chamber. Next, the plasma power was increased to 500-1000 W and the helium flow rate was increased to 1000-4000 sccm, and the deposited silicon oxide film was subjected to plasma treatment for 6-20 seconds under these conditions. The temperature and pressure of...

Embodiment 2

[0091] Example 2. Structure of the formed low stress film.

[0092]Acquisition of FT IR spectra of low stress silicon oxide materials. Films were formed as described in Example 1 using the following process parameters: temperature 180 °C, pressure 3.5 Torr, plasma power 100 W (generated at 13.56 Mhz), SiH 4 Flow rate 30sccm, CO 2 Flow rate 4200 seem and He flow rate 1250 seem. The stress of the formed film is less than -40 MPa. It can be seen that the FT IR spectrum at about 2250cm -1 There is no Si-H peak at , which is usually present in silicon oxide films deposited by low-temperature PECVD without plasma post-treatment. This indicates that the plasma post-treatment reduces the hydrogen concentration in the formed film.

Embodiment 3

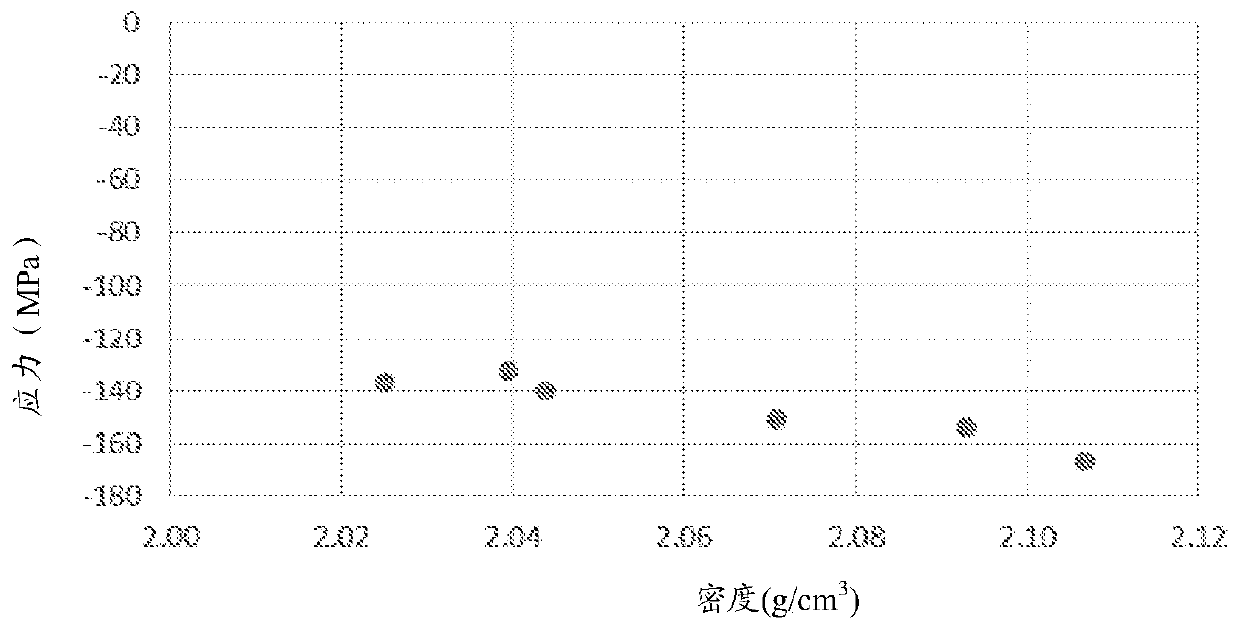

[0093] Example 3. Improvement of stress, density and RI by plasma post-treatment.

[0094] Silicon oxide films were deposited by low-temperature PECVD to a thickness of 411 angstroms, and their stress, density, and RI were measured. 30 sccm of SiH at a temperature of 180°C and a pressure of 3.5 Torr using a plasma power of 100W (13.56Mhz) 4 Flow Rate, 4200sccm CO 2 flow rate and a He flow rate of 1250 seem for deposition.

[0095] Another silicon oxide film was deposited by low-temperature PECVD using the same process conditions as those used in the deposition of the comparative film above, and then at a temperature of 180° C. using a plasma power of 500 W (13.56 Mhz) and a He flow rate of 1000 sccm, Plasma treatment was performed at a pressure of 3.5 Torr. The stress, density and RI of the treated films were measured.

[0096] Parameters for the comparative and treated membranes are provided in Table 4.

[0097] Table 4. Improvement in stress, density and RI upon plasma ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com