A high-performance aluminum alloy plate transverse vibration rolling process

An aluminum alloy plate, transverse vibration technology, applied in the direction of metal rolling, can solve the problem of uneven grain refinement, and achieve the effect of improving mechanical properties, good insulation and fast cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

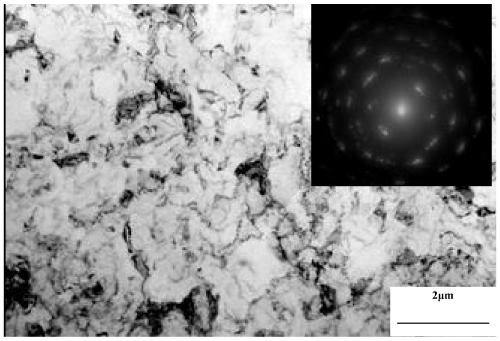

Image

Examples

Embodiment 1

[0053] For the transverse vibration rolling process of AA5052 alloy material, the chemical composition mass fraction of AA5052 alloy is 0.09% Si, 0.24% Fe, 0.02% Cu, 0.06% Mn, 2.3% Mg, 0.19% Cr and 0.1% Zn, and the balance is Al , cut it into a sample with a shearing machine, and the rolling process is as follows:

[0054] (1) Put the AA5052 alloy sample into the heating furnace, raise the temperature to 350°C, heat preservation annealing treatment for 1 hour, and then cool to room temperature with the furnace to eliminate the residual stress of the sheet metal and facilitate subsequent transverse vibration rolling;

[0055] (2) Implement transverse vibration rolling on the annealed plate, the rolling temperature is set to 100 °C, the reduction rate of each rolling pass is 40%, rolling 4 times, the transverse vibration frequency of the lower roll is 5Hz , 4-pass rolling amplitude is selected as 1mm, and the total thickness of transverse vibration rolling is reduced by 87%;

...

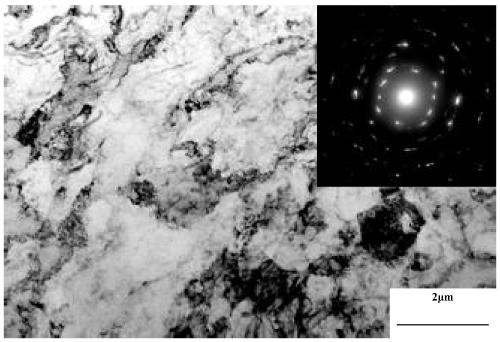

Embodiment 2

[0058] Embodiment 2 The transverse vibration rolling process of the AA5052 alloy material is basically the same as that of Embodiment 1, the difference is that in step (2), the rolling amplitude of the 4 passes is 0mm.

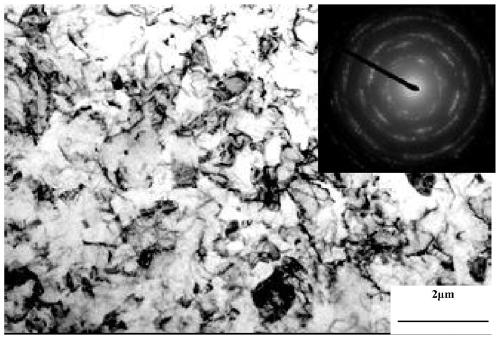

Embodiment 3

[0060] Embodiment 3 The transverse vibration rolling process of the AA5052 alloy material is basically the same as that of Embodiment 1, the difference is that in step (2), the rolling amplitude of the 4 passes is 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com