Tool turret device applied to machine tool with Y axis

A Y-axis and turret technology, which is applied in the field of machine tools, can solve problems such as impracticability, and achieve the effects of centering adjustment, widening the processing range, and convenient centering adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

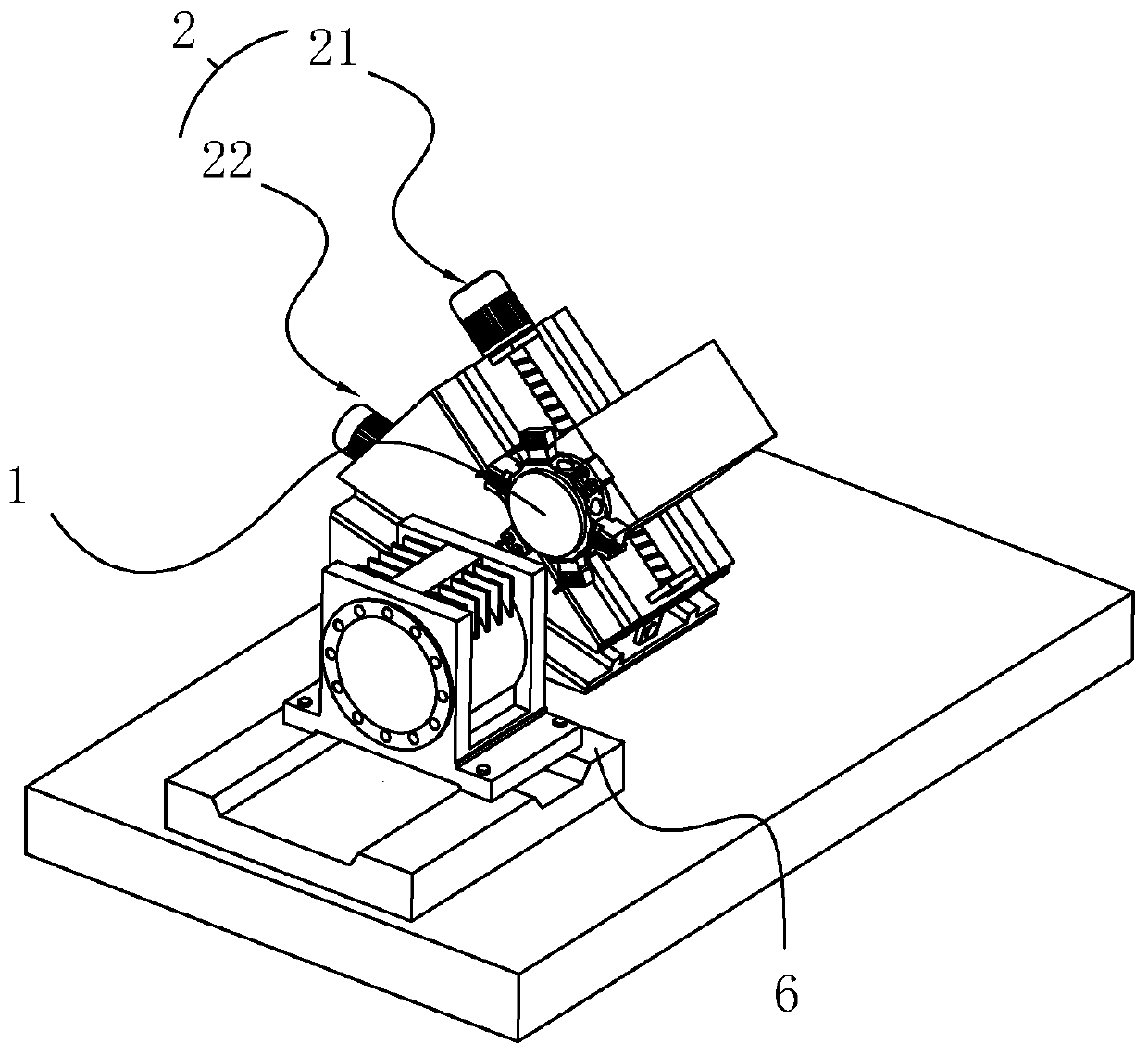

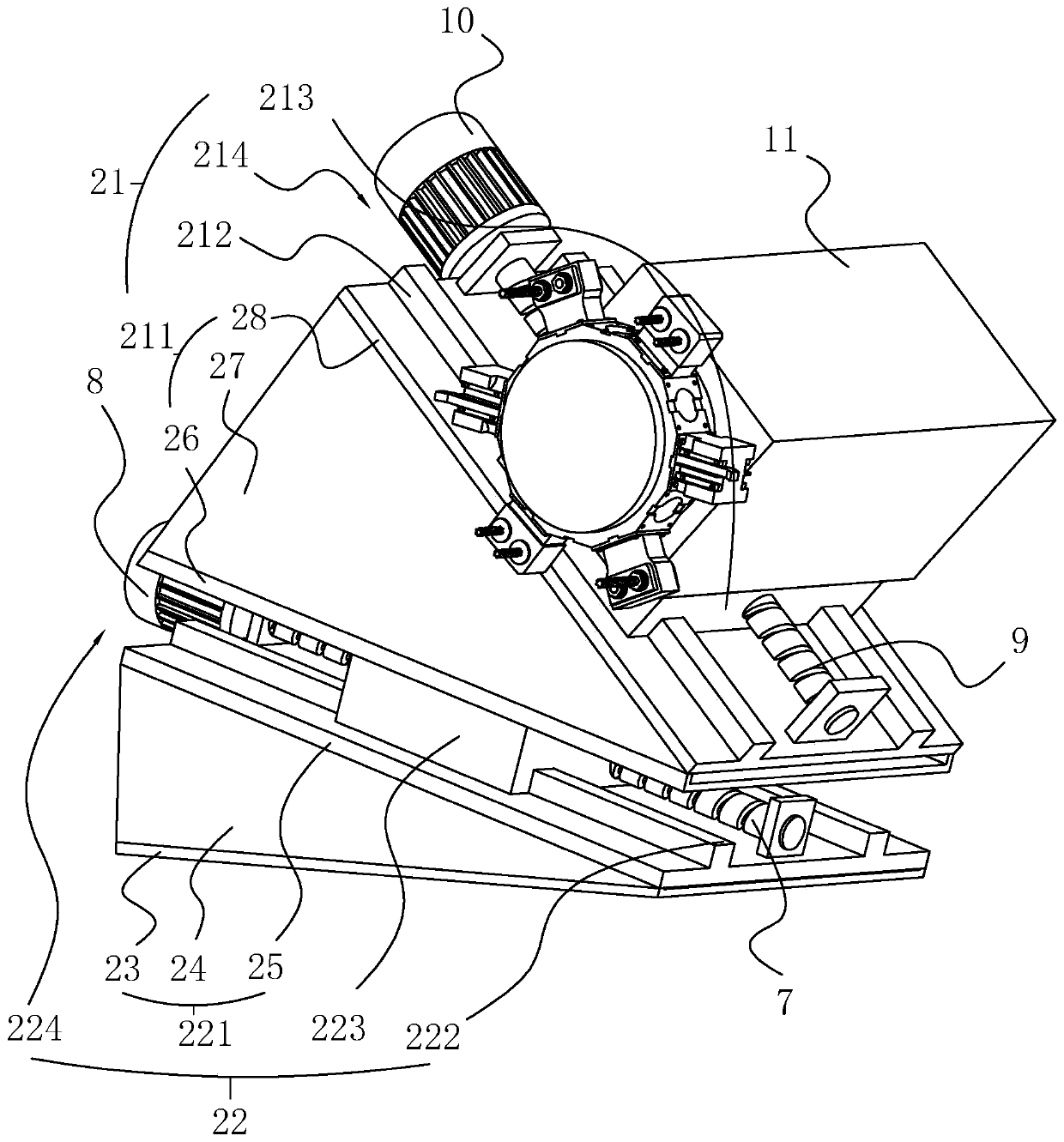

[0035] A kind of turret device applied to a machine tool with Y axis, refer to figure 1 As shown, it includes a turret 1 and a drive mechanism 2. The drive mechanism 2 includes an X-axis drive assembly 21 and a Y-axis drive assembly 22. The Y-axis drive assembly 22 drives the X-axis drive assembly 21 to move, and the X-axis drive assembly 21 Drive the turret 1 to move, and under the action of the Y-axis drive assembly 22, the moving direction of the X-axis drive assembly 21 forms an angle of 15° with the spindle installation reference plane 6. Under the action of the X-axis drive assembly 22, the movement direction of the turret 1 The direction of movement is 30° to the spindle installation datum plane 6 .

[0036] refer to figure 2 As shown, the Y-axis drive assembly 22 includes a Y-axis slant support plate 221 fixedly installed on the machine bed. The Y-axis slant support plate 221 includes a Y-axis base plate 23 fixed on the machine bed. The reference plane 6 is parallel...

Embodiment 2

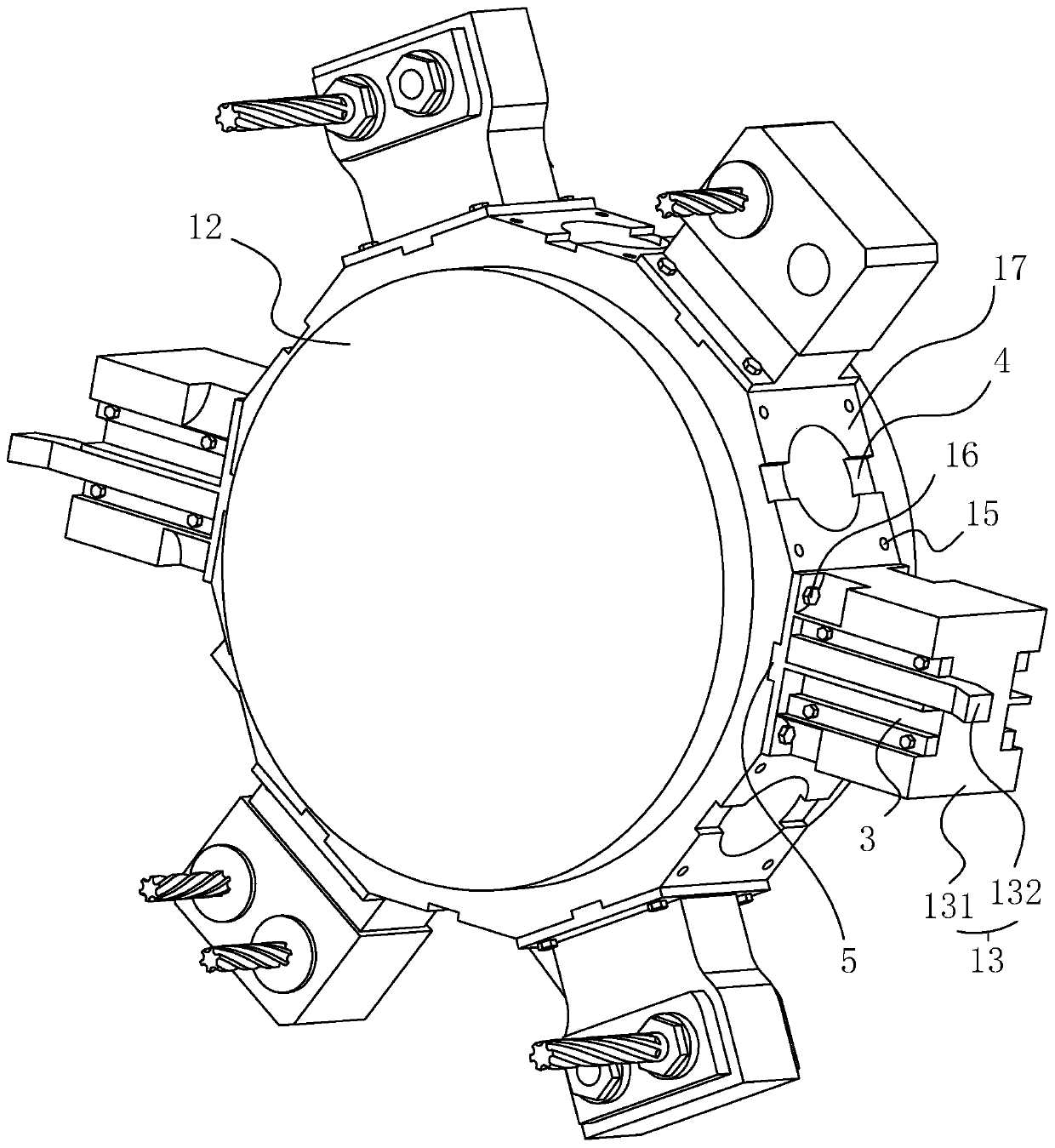

[0042] A turret device applied to a machine tool with a Y axis, the difference from Embodiment 1 is that, refer to Figure 4 As shown, the installation position 3 is at least two installation holes opened along the central axis of the cutter head 12 on the side wall of the fixed knife seat 131 parallel to the end face of the cutter head 12, and a cutter head 132 can be inserted into the installation holes. , The cutter head 132 is a drill bit or a milling cutter, and is locked by a locking bolt.

Embodiment 3

[0044] A turret device applied to a machine tool with a Y axis, the difference from Embodiment 1 is that, refer to Figure 5 As shown, on the mounting surface 17 of the cutter head 12, there are fixed holes 18 arranged radially along the cutter head 12, and a power tool 14 can be installed in the fixed hole 18. The power tool 14 is a power head, and the power head can be selected to have at least Two-axis drilling / milling driven tool holder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com