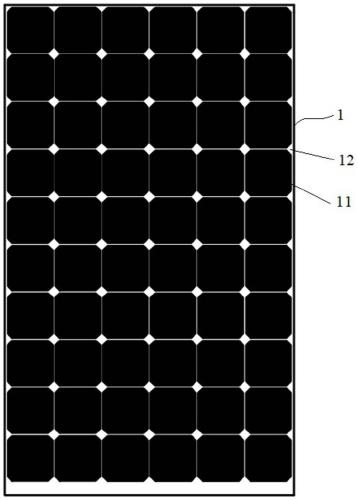

Patterned photovoltaic backplate and preparation method thereof

A photovoltaic backplane and patterning technology, applied in the field of solar cells, can solve the problems of difficult construction of reflective coatings and attenuation of adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepare the ink according to the formula listed in Table 1, use a transparent base layer, and screen-print the surface (EVA surface) that is in contact with the packaging material. The graphite position corresponds to the gap position of the solar cell, and then bake in a 160°C oven After 3 minutes, a patterned photovoltaic backplane was prepared, wherein the thickness of the ink layer was 30 microns.

[0036] Table 1

[0037] Types of

[0038] Note: The proportions in the table are weight ratios.

Embodiment 2

[0040] Prepare the ink according to the formula listed in Table 2, use a white base layer, and screen-print the surface (EVA surface) that is in contact with the packaging material. The position of the graphite corresponds to the gap position of the solar cell, and then bake in an oven at 150°C After 2.5 minutes, a patterned photovoltaic backplane was prepared, in which the thickness of the ink layer was 20 microns.

[0041] Table 2

[0042] Types of

[0043] Note: The proportions in the table are weight ratios.

Embodiment 3

[0045] Prepare the ink according to the formula listed in Table 3, use a transparent base layer, and screen-print the surface (EVA surface) that is in contact with the packaging material. The position of the graphite corresponds to the gap position of the solar cell, and then bake in a 100°C oven After 5 minutes, a patterned photovoltaic backplane was prepared, wherein the thickness of the ink layer was 30 microns.

[0046] table 3

[0047] Types of

[0048] Note: The proportions in the table are weight ratios.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com