Low-alloy high-strength hot-rolled steel strip suitable for extremely cold area and preparation method thereof

A low-alloy, high-strength, regional technology, used in metal processing equipment, manufacturing tools, casting equipment, etc., can solve the problem of small number of Mg-Ti series composite oxides, insufficient number of small inclusions, and unreasonable feeding of magnesium-containing alloys. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Any feature disclosed in this specification, unless specifically stated, can be replaced by other alternative features that are equivalent or have similar purposes. Unless expressly stated otherwise, each feature is only one example of a series of equivalent or similar features. The description is only to help the understanding of the present invention, and should not be regarded as a specific limitation on the present invention.

[0056] The billet composition of embodiment sees the following table 3;

[0057] Table 3 embodiment billet composition

[0058]

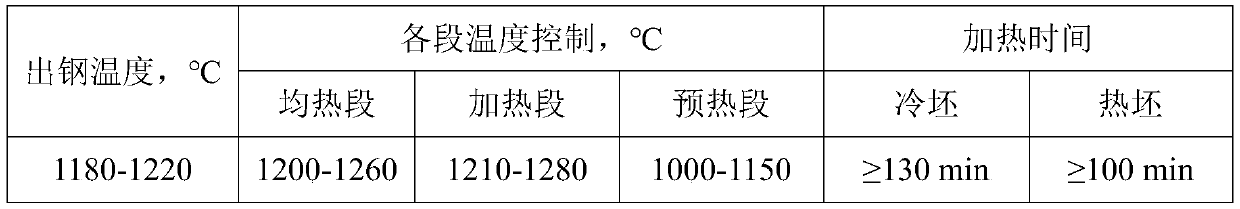

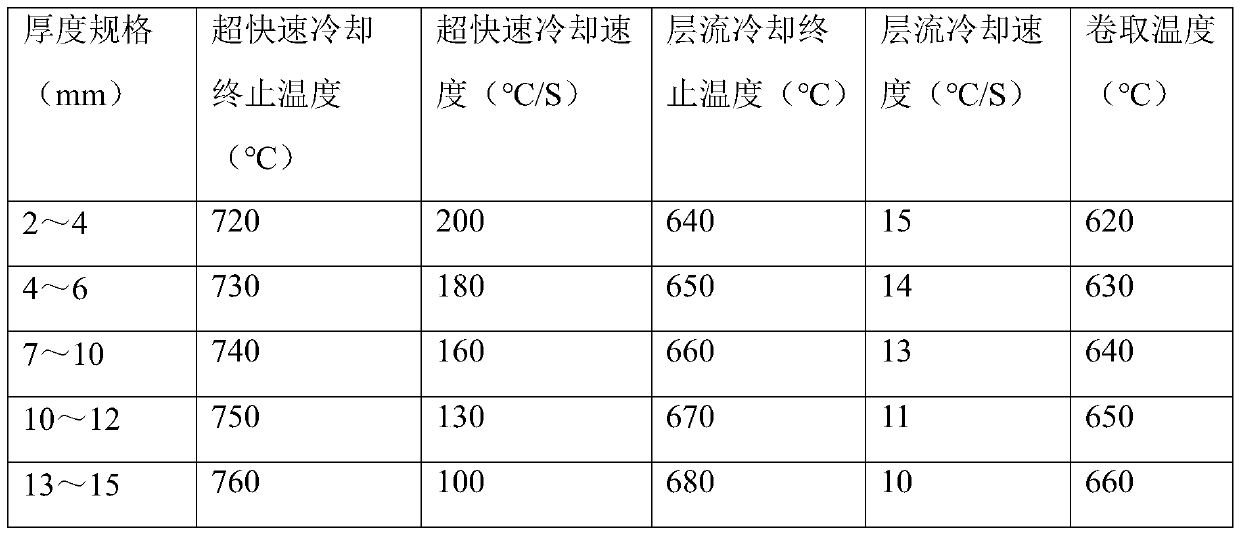

[0059] The technical process of the embodiment adopts the technical process described in the summary of the invention, and the rolling and post-rolling cooling process of the embodiment are shown in Table 4 below;

[0060] The rolling of table 4 embodiment and post-rolling cooling process

[0061]

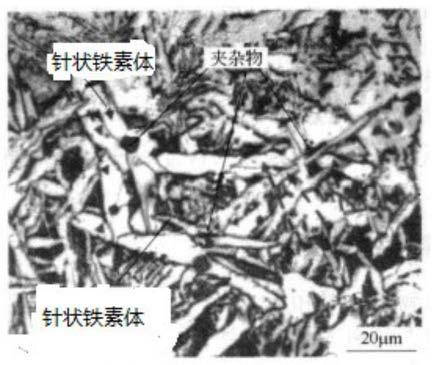

[0062] The density of inclusions, mechanical properties, and organization of the rolling material of the embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com