Regular microporous film and preparation method and application thereof

A microporous membrane and regular technology, applied in the field of microfluidics, can solve the problems of complex microporous membrane technology, difficulty in achieving uniform pore size, controllable pore spacing, etc., and achieve uniform pore size, simple preparation method, environment and equipment. require less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

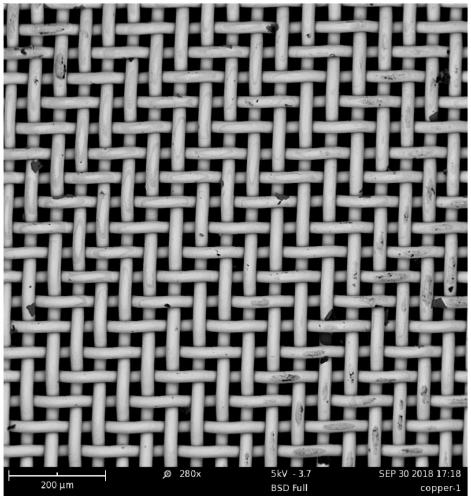

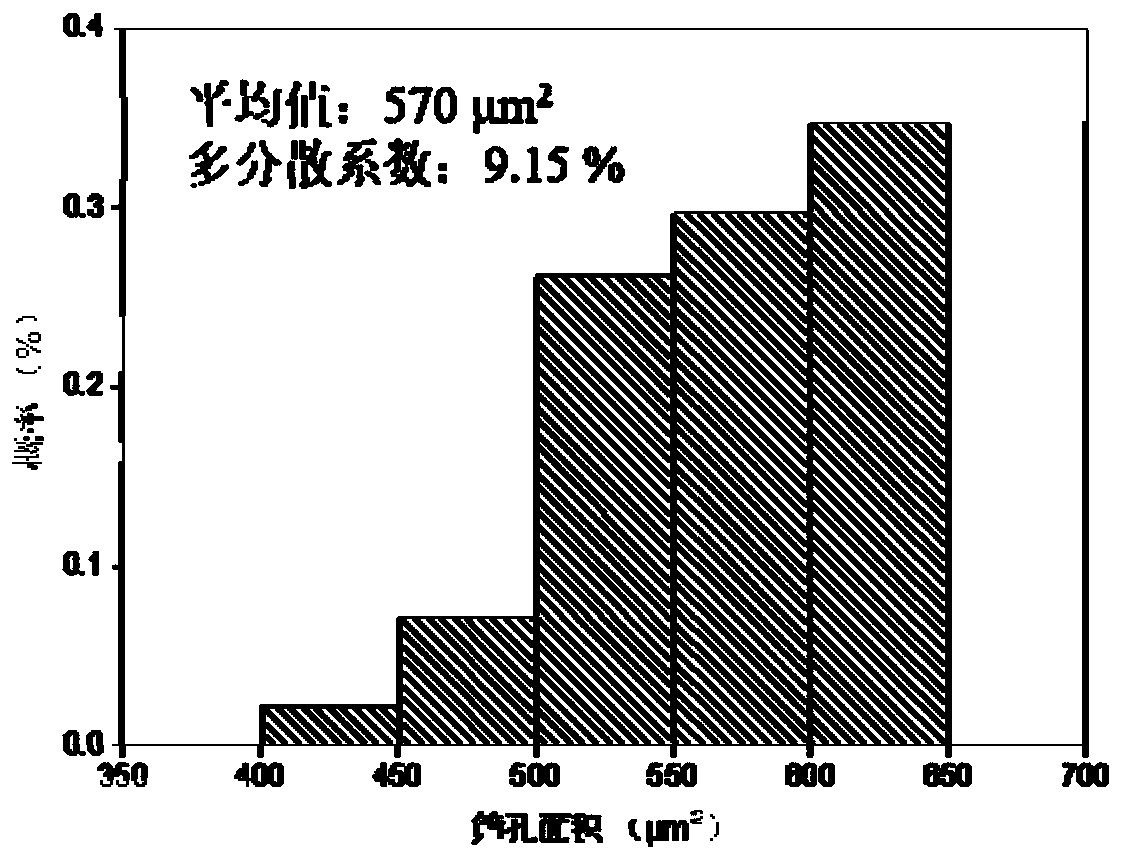

[0051] This embodiment provides a regular microporous membrane.

[0052] Its preparation method comprises the following steps:

[0053] (1) Cut the 500-mesh (aperture 25 μm, hole spacing 24 μm) standard sample screen into small pieces with a width of 0.5 cm and a length of 1 cm;

[0054] (2) The screen cloth obtained in (1) is successively cleaned with deionized water and absolute ethanol;

[0055] (3) Soak the cleaned screen with 1.5% hydrochloric acid until there is no observable rust;

[0056] (4) Immerse the treated screen into 8-12g / L copper, 80-130g / L hydroxyethylidene diphosphate, 6-12g / L potassium tartrate, 40-60g / L potassium carbonate, and 2-4g / L hydrogen peroxide. The plating solution of L is used as the cathode, and a piece of pure copper is used as the anode to immerse in the plating solution;

[0057] (5) Use the digital source meter as the power supply, the power supply mode is a constant current of 10mA, and the power supply lasts for 1 hour.

[0058] Among th...

Embodiment 2

[0061] This embodiment provides a regular microporous membrane.

[0062] Its preparation method comprises the following steps:

[0063] (1) Cut the 500-mesh (aperture 25 μm, hole spacing 24 μm) standard sample screen into small pieces with a width of 0.5 cm and a length of 1 cm;

[0064] (2) The screen cloth obtained in (1) is successively cleaned with deionized water and absolute ethanol;

[0065] (3) Soak the cleaned screen with 1.5% hydrochloric acid until there is no observable rust;

[0066] (4) Immerse the treated screen into 8-12g / L copper, 80-130g / L hydroxyethylidene diphosphate, 6-12g / L potassium tartrate, 40-60g / L potassium carbonate, 2-4g / L hydrogen peroxide The plating solution of L is used as the cathode, and a piece of pure copper is used as the anode to immerse in the plating solution;

[0067] (5) Use the digital source meter as the power supply, the power supply mode is a constant current of 10mA, and the power supply lasts for 2 hours.

[0068] Among them...

Embodiment 3

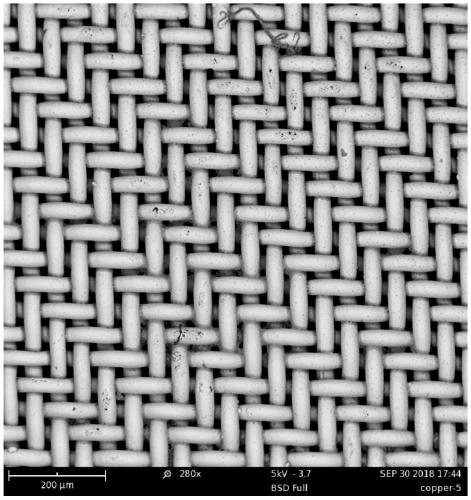

[0071] This embodiment provides a regular microporous membrane.

[0072] Its preparation method comprises the following steps:

[0073] (1) Cut the 500-mesh (aperture 25 μm, hole spacing 24 μm) standard sample screen into small pieces with a width of 0.5 cm and a length of 1 cm;

[0074] (2) The screen cloth obtained in (1) is successively cleaned with deionized water and absolute ethanol;

[0075] (3) Soak the cleaned screen with 1.5% hydrochloric acid until there is no observable rust;

[0076] (4) Immerse the treated screen into 8-12g / L copper, 80-130g / L hydroxyethylidene diphosphate, 6-12g / L potassium tartrate, 40-60g / L potassium carbonate, and 2-4g / L hydrogen peroxide. The plating solution of L is used as the cathode, and a piece of pure copper is used as the anode to immerse in the plating solution;

[0077] (5) Use the digital source meter as the power supply, the power supply mode is a constant current of 10mA, and the power supply lasts for 3 hours.

[0078] Among...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com