Drill splitting trolley for tunnel excavation

A technology of tunnel excavation and trolley, which is applied in the direction of tunnels, drilling equipment, earthwork drilling and mining, etc. It can solve the problems that affect the utilization rate of drilling operation time, the difficulty of controlling over-excavation and under-excavation in blasting, and the harmful effects of surrounding rocks and other problems, to achieve the effect of reducing support workload, simple and convenient construction process, and reducing the rate of over- and under-excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

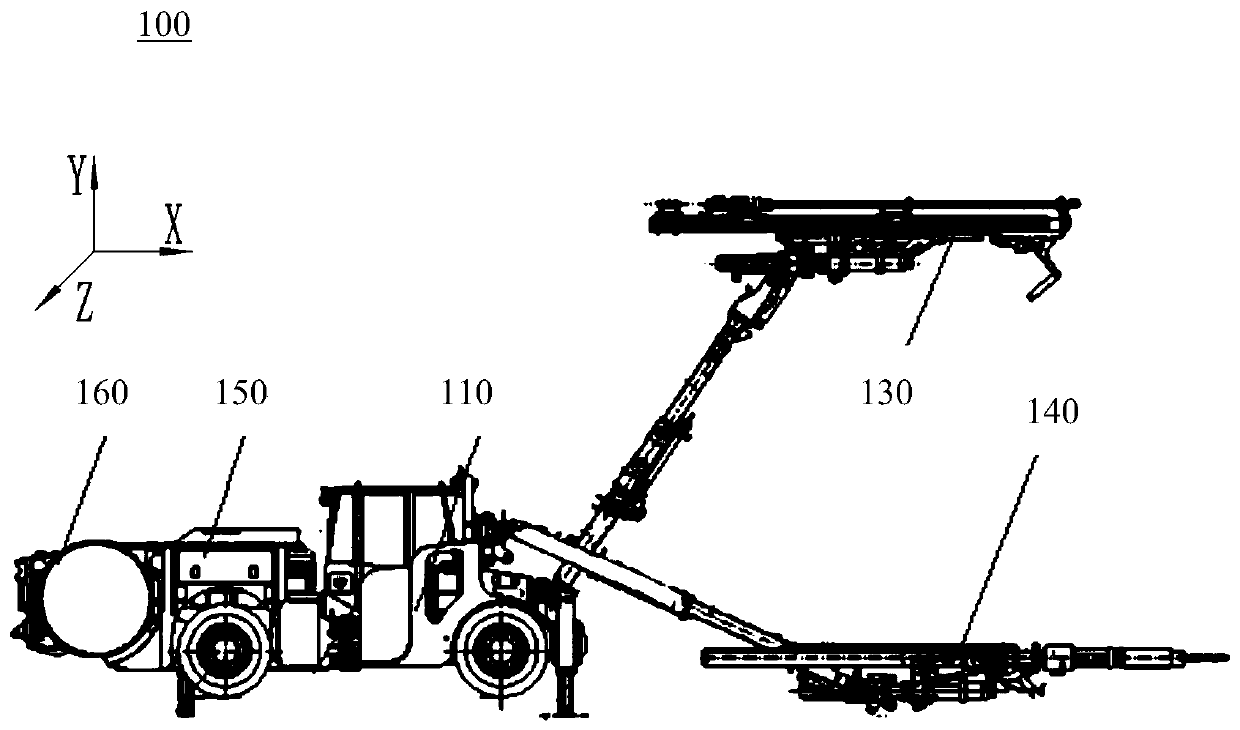

[0033] The present invention is introduced below by accompanying drawing.

[0034] In this application, it should be noted that the directional terms or qualifiers "upper", "lower", "left", "right", "front", "rear" etc. used in this application are for the for the accompanying drawings. specifically with figure 1 The coordinate indication in , the direction indicated by X is defined as the front or similar terms, and the opposite direction is defined as the rear or similar terms, that is, the forward end of the drilling and splitting rig used for tunnel excavation is defined as the front end or similar terms , and the end opposite to the forward end is defined as the back end or similar terms. The direction indicated by Y is defined as up or similar terms, and the direction opposite thereto is defined as down or similar terms. The direction indicated by Z is defined as right or a similar term, and the direction opposite thereto is defined as left or a similar term. They ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com