Condensing extraction back-pressure coupling steam extraction integrated system for thermoelectric unit power peak shaving and operation method thereof

A thermoelectric unit and integrated system technology, applied in the direction of steam application, mechanical equipment, steam engine equipment, etc., can solve the problems of steam parameters that cannot meet the demand, residual pressure loss, etc., to improve thermoelectric decoupling operation capacity, reduce utilization, and meet power requirements The effect of peak shaving and FM requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0038] Example.

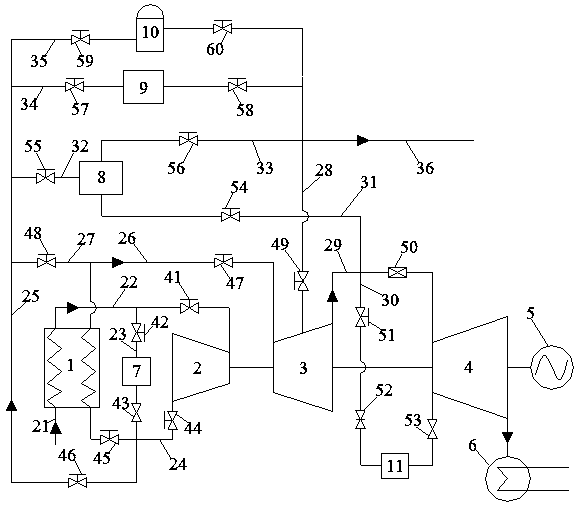

[0039] see figure 1 , the condensate-pump back-coupling steam extraction integrated system for power peak regulation of thermal power units in this embodiment includes: power plant boiler 1, steam turbine high-pressure cylinder 2, steam turbine medium-pressure cylinder 3, steam turbine low-pressure cylinder 4, generator 5, condensing Steam boiler 6, first temperature and pressure reduction device 7, pressure matching device 8, second temperature and pressure reduction device 9, steam heat storage device 10 and temperature reduction device 11.

[0040] The high pressure cylinder 2 of the steam turbine, the medium pressure cylinder 3 of the steam turbine and the low pressure cylinder 4 of the steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com