Setting machine waste gas treatment equipment cluster remote monitoring and operation and maintenance system

A technology for waste gas treatment and remote monitoring, applied in transmission systems, signal transmission systems, measurement devices, etc., can solve the problems of high operation and maintenance costs, scattered treatment equipment layout, high temperature, and reduce manual inspection and maintenance costs. , The effect of improving operation stability and safety, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

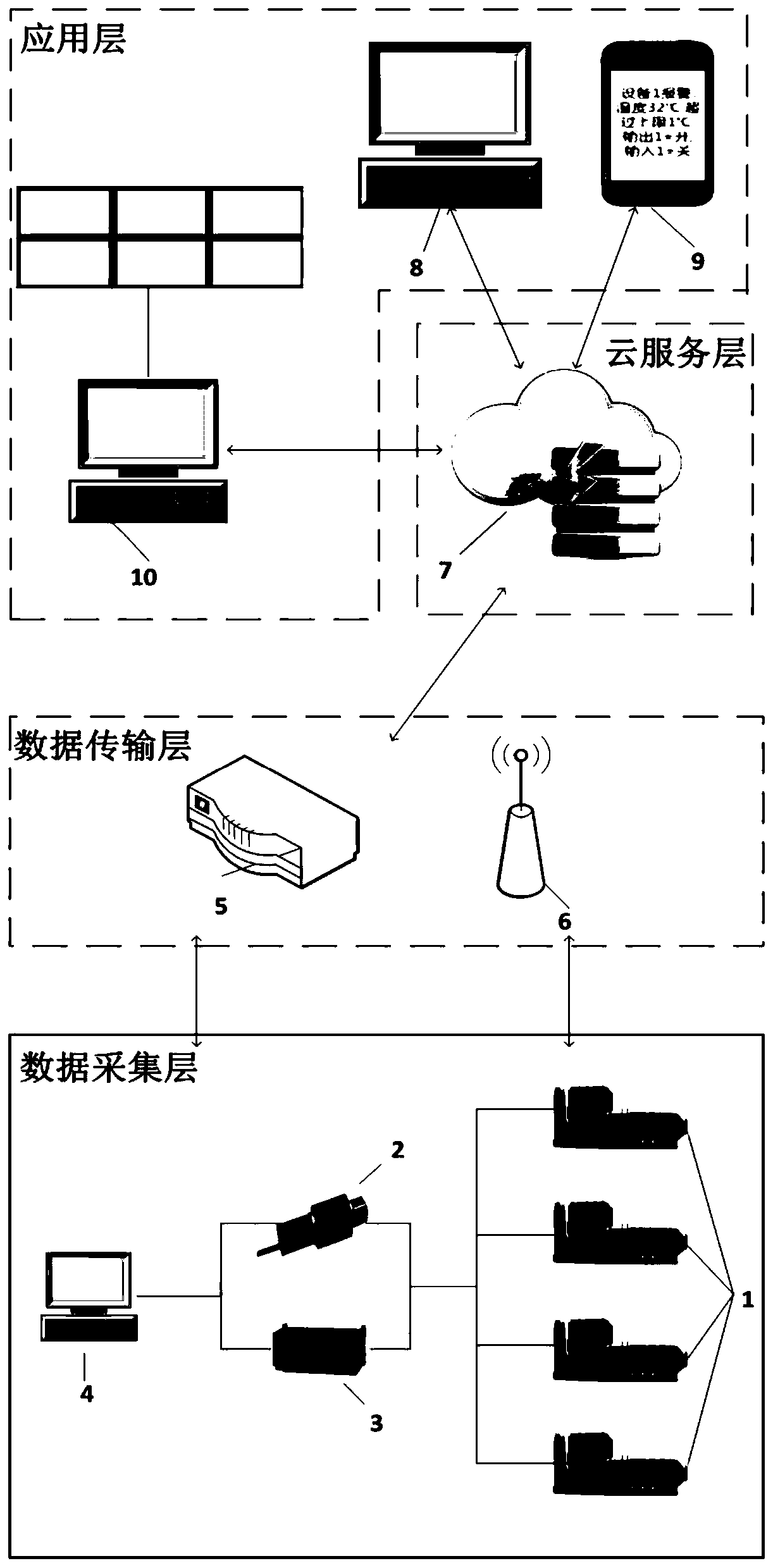

[0034] In this example, combined with figure 1 As shown, the remote monitoring and operation and maintenance system of the exhaust gas treatment equipment cluster of the setting machine includes a data acquisition system, a data transmission system, a cloud service system and a terminal application system. Cloud service system signal connection, the cloud service system and the terminal application system signal connection, this embodiment adopts a layered structure design, through the application of Internet communication and cloud service technology, real-time data display and Monitoring achieves the technical effect of high-efficiency human-computer interaction.

[0035] Such as figure 1 As shown, the remote monitoring and operation and maintenance system architecture diagram of the waste gas treatment equipment cluster of the setting machine in this embodiment is provided, and the operating data and working condition data (including temperature , humidity, spray volume, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com