Prestressed concrete cylinder pipe preparation method

A technology of concrete pipes and prestressed steel, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of impact resistance, low load-bearing capacity, inconvenient operation, easy damage, etc., to achieve enhanced load-bearing capacity, cost savings, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

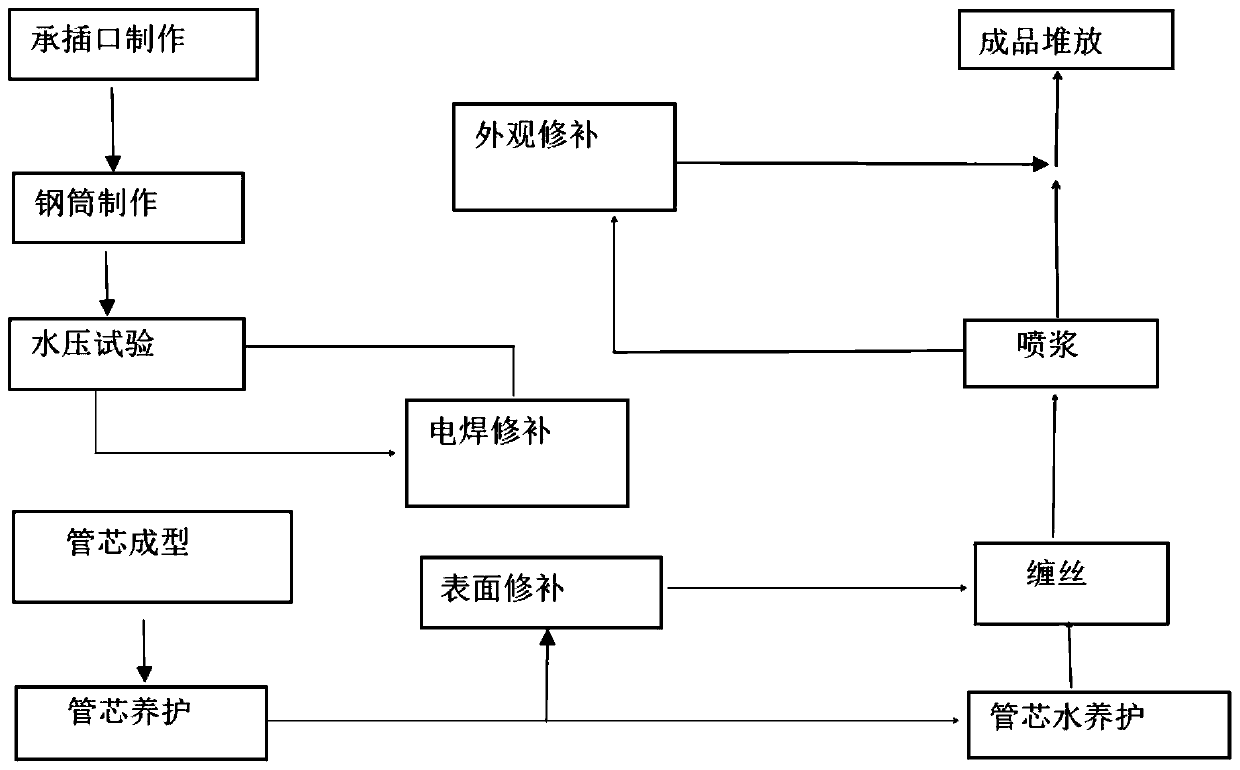

[0038] A kind of preparation method of prestressed steel cylinder concrete pipe, such as figure 1 Shown, including socket production, steel cylinder production, hydrostatic test, electric welding repair, tube core forming, tube core maintenance, surface repair, tube core water curing, wire winding, spraying, appearance repair and finished product stacking, specific operation steps as follows:

[0039] S1: Place the coil plate with a thickness of 1.5mm as the raw material on the unwinding mechanism of the spiral welding machine, install the mandrel according to the required specifications, and make the steel cylinder;

[0040] S2: Cut the socket plate and socket plate to length, preliminarily roll the socket plate and socket plate on the rolling machine, and weld the joint seam;

[0041] S3: Lift the initially rounded socket ring to the pressure roller of the edging machine, and edge the socket;

[0042] S4: Assemble the rounded socket rings and socket rings on the socket ass...

Embodiment 2

[0052] As the second embodiment of the present invention, the concrete batching parameters are shown in the following table:

[0053]

[0054]

[0055] It is worth noting that the table in this embodiment is a reference table, and the actual use is produced according to the concrete mix ratio issued by the technical department.

Embodiment 3

[0057] As a third embodiment of the present invention, the process parameters of the die are shown in the following table:

[0058]

[0059] It is worth noting that the speed is measured by speed-regulating motor revolutions per minute, and the time is measured by minutes. The slow and medium speeds should be gradually increased within the range, and the interval between each increase is about 1 minute; the fast time can be based on the temperature, concrete slump The speed and rotation speed can be increased or decreased as appropriate; the fast rotation speed should be adjusted appropriately depending on the smoothness of the pipe mold operation to ensure safety.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com