Protective agent for improving self-protection capability of cement concrete in active service and preparation method of protective agent

A technology of cement concrete and protective agent, applied in the direction of anti-corrosion paint, coating, etc., can solve the problems of falling off, weakened protective effect, loss, etc., and achieve the effect of improving waterproof, low application cost and simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing a protective agent for improving the self-protection ability of cement concrete in active service, which is used to prepare the above-mentioned protective agent for improving the self-protection ability of cement concrete in active service. Specifically, the method may include the following steps:

[0040] Step 1. According to the above formula of the protective agent for improving the self-protection ability of the active cement concrete, weigh the methyl silicone resin, orthosilicic acid and double alkali solution.

[0041] Step 2, firstly add the double alkali solution to the open reaction kettle, then slowly add the silicic acid and the orthosilicic acid to the reaction kettle while stirring in random order, and the stirring speed can be 60 ~120 rev / min, to avoid the one-time dosage is too large and the temperature rises too fast, the temperature in the reaction kettle is controlled between 70 ℃ ~ 90 ℃, and t...

Embodiment 1

[0059] A protective agent for improving the self-protection ability of active cement concrete, the preparation method of which comprises the following steps:

[0060] Step 1A, the preparation of silicone resin: add distilled water in the empty reactor, then add monomethyltrichlorosilane to the reactor while stirring, the weight ratio of the monomethyltrichlorosilane to the distilled water Be 1:8, regulate and control the temperature of described reaction kettle, make the liquid temperature in described reaction kettle controlled at 50 ℃, the stirring blade rotation speed that described reaction kettle stirs is 60 rev / min, the reaction time is 150 minutes, a methyl Trichlorosilane is distilled and hydrolyzed to obtain a mixture containing silicone resin; the mixture containing silicone resin is filtered with a 50-micron screen, the liquid part is removed, and the liquid part is stored in a storage tank for continued use in the next production, obtaining Solid phase substance; a...

Embodiment 2

[0072] A protective agent for improving the self-protection ability of active cement concrete, the preparation method of which comprises the following steps:

[0073] Step 1B, preparation of silicone: the same as step 1A in Example 1 of the present invention.

[0074] Step 2B, preparation of orthosilicic acid: the same as step 2A in Example 1 of the present invention.

[0075] Step 3B, preparation of double alkali solution: the same as step 3A in Example 1 of the present invention.

[0076] Step 4B, synthesis: it is basically the same as step 4A in Example 1 of the present invention, and the difference is only that: the weight ratio of the silicone resin to the orthosilicic acid and the double alkali solution is 2:3:5 , not 3:2:5.

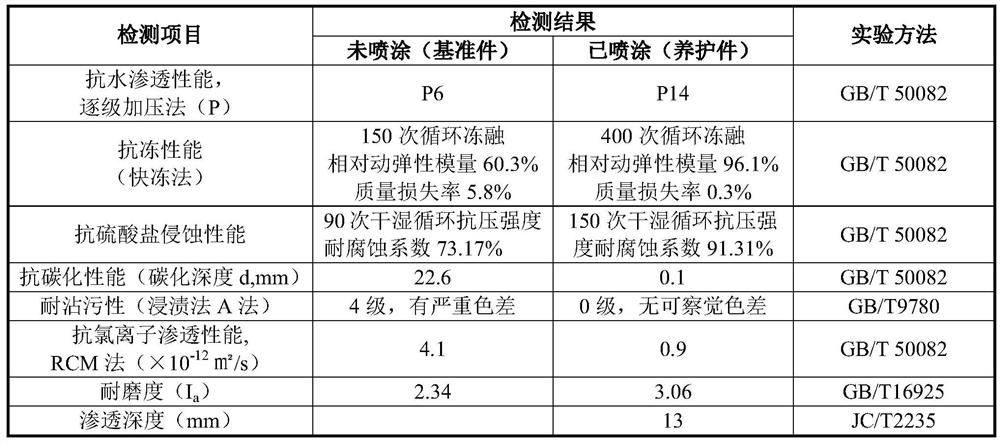

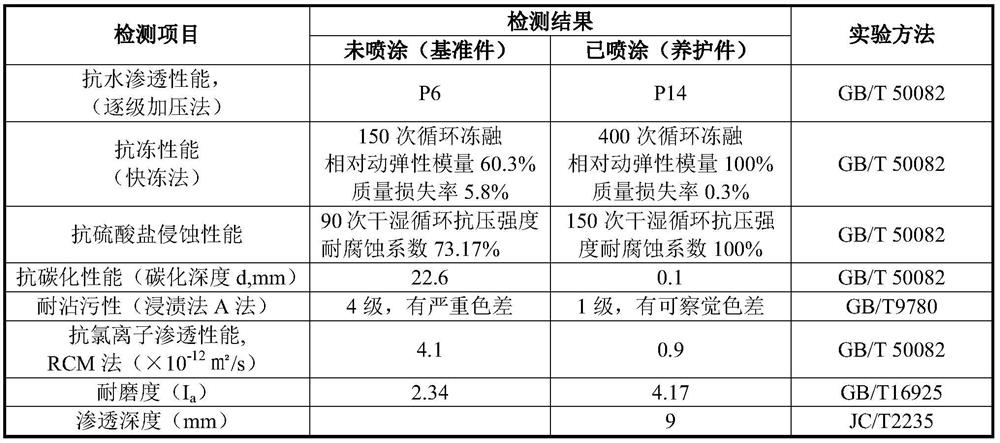

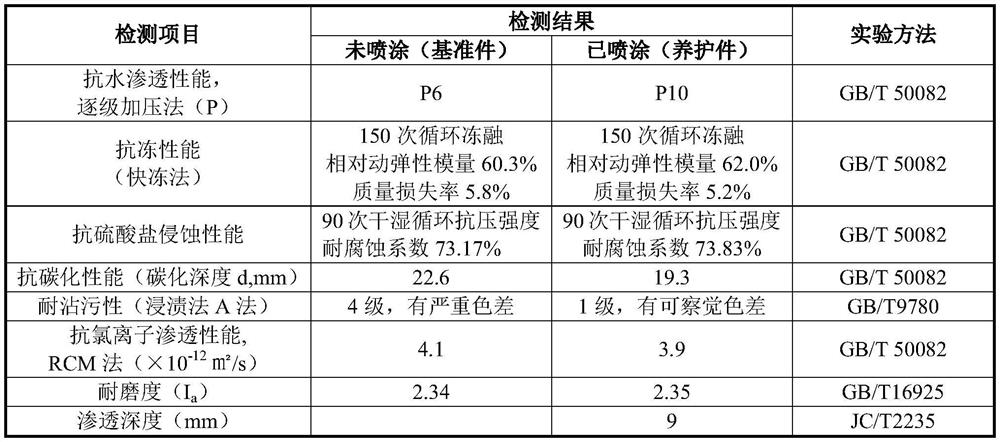

[0077] Specifically, the protective agent that improves the self-protection ability of active cement concrete prepared by the embodiment of the present invention 2 is subjected to the detection of the following product properties and protective p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com