Mixing machine for bridge wet joint filler

A technology for wet joints and filling materials, which is applied in the direction of unloading device, mixing operation control, cement mixing device, etc., can solve the problem of easy agglomeration of the mixture and the effect of mixing, achieve good screening effect, save materials, The effect of improving the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

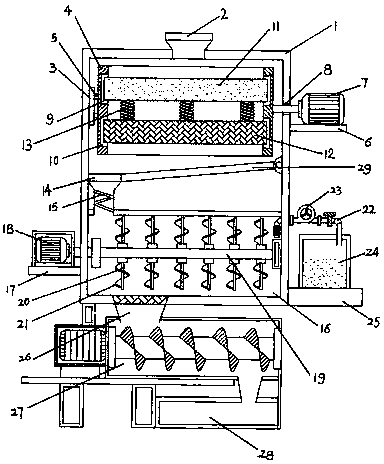

[0012] The present invention is described in detail below in conjunction with accompanying drawing:

[0013] A mixing machine for bridge wet joint filling materials, comprising a tank body 1, the upper part of the tank body 1 is a sieving bin, the lower part of the tank body 1 is a mixing bin 16, and the top surface of the tank body 1 is provided with an inlet The feed port 2 is provided with a discharge port 26 on the bottom end surface of the tank body 1, a support bearing 3 is provided on the left side inner wall of the upper inner part of the tank body 1, and a support bearing 3 is arranged on the right inner side wall of the upper inner part of the tank body 1. There is a sieve frame turning drive motor shaft extending into the hole 8, a sieve frame 4 is arranged in the sieve bin, a sieve frame left support shaft 5 is arranged on the left end outer surface of the sieve frame 4, and the sieve frame left support shaft The outer side end of 5 is arranged in the support beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com