Box type winding device for belt material storage

A material storage and strip technology, which is applied in the field of disposable sanitary products, can solve the problems of unsmooth production, easy failure of equipment, and high labor intensity of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

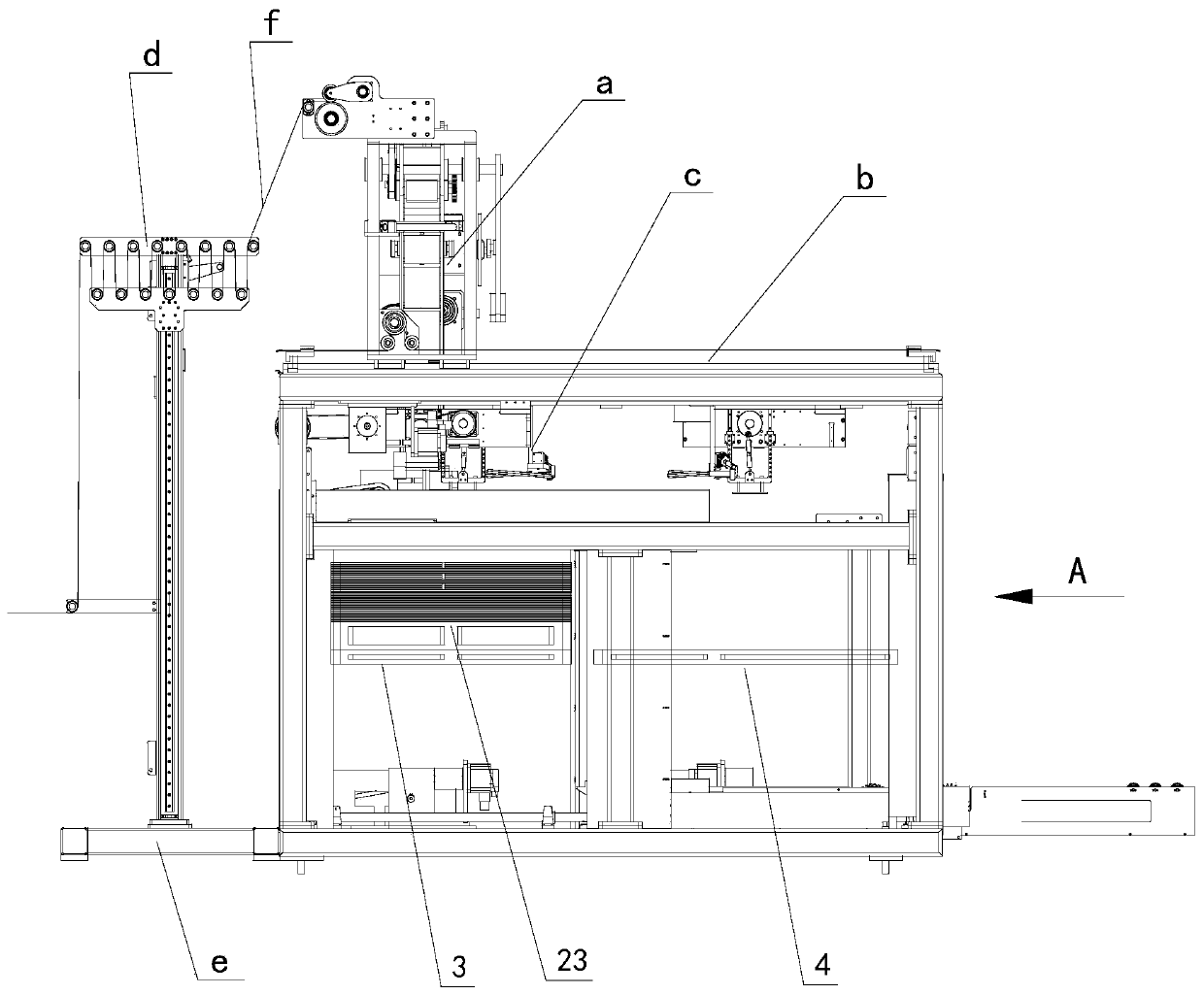

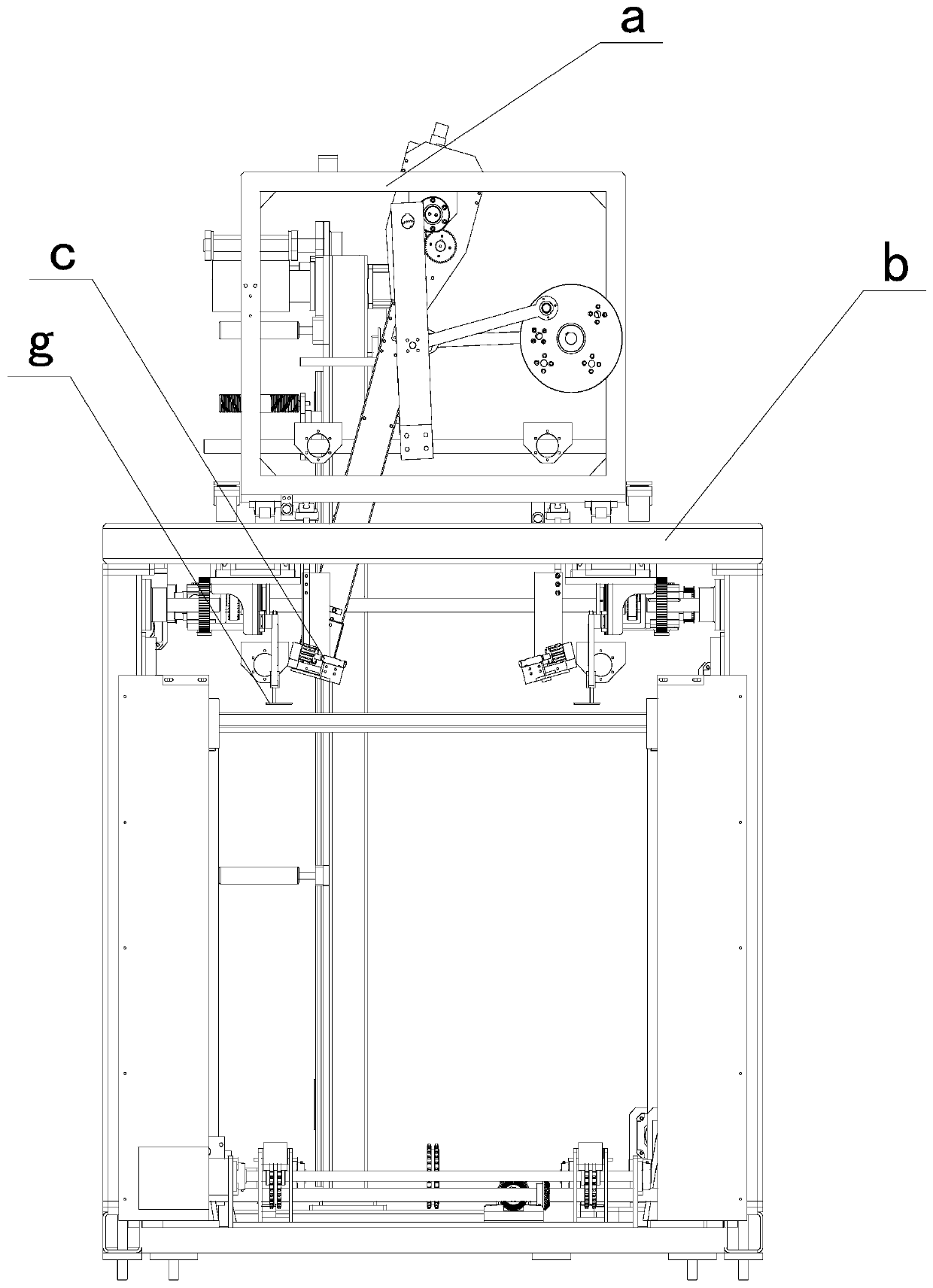

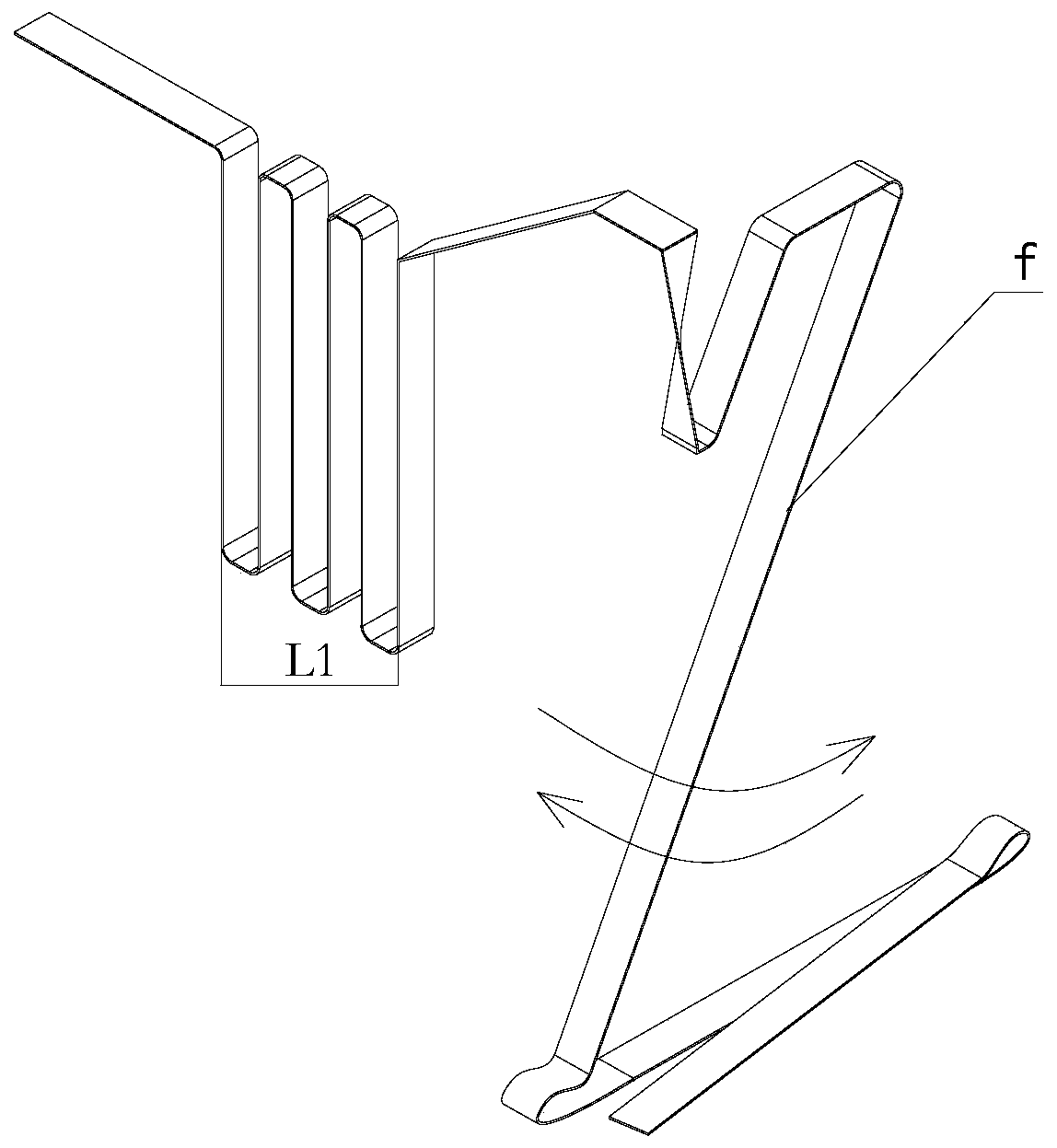

[0054] A kind of box-type rewinding equipment that present embodiment is used for strip material storage, such as figure 1 or figure 2 As shown, it includes a swing-type folding device a and a storage device b. The storage device is provided with a strip storage station 3 and a pallet backup station 4. The strip storage station is also provided with a cutting mechanism c . When the box-type winding equipment is used, its principle is: the strip f on the strip production line is continuously fed into the swing-type folding device by the feeding mechanism d at the end, and the strip storage station in the storage device is set There is a pallet for material storage, and the swing-type folding device performs a swinging action and a translation action on the strip material storage station at the same time, so that the strip is continuously folded on the pallet (such as figure 2 Indicated by the arrow in ), finally forming a box-like storage state (such as image 3 shown); wh...

Embodiment 2

[0083] A kind of box-type winding equipment that this embodiment is used for strip material storage, compares with embodiment 1, and its difference is: as Figure 16 As shown, in the material storage device, a limiting part 24 is also provided between the strip material storage station and the pallet backup station located below the pallet replacement channel. This structure is mainly used when multiple spare pallets are stored in the pallet spare station for use. During the pallet replacement process, the push rod sends out the top pallet each time, and the bottom pallet is The limit part is blocked and fixed on the supporting plate spare station. After the uppermost supporting plate is sent out, the lower supporting plate is lifted up for use.

[0084] In this embodiment, the limiting part is a cross bar arranged between the strip material storage station and the pallet backup station. Or slightly greater than the height of a single pallet, this structure is more convenient...

Embodiment 3

[0093] This embodiment is a kind of box-type winding equipment for strip material storage. Compared with Embodiment 2, its difference lies in: (1) in the first lifting mechanism on the strip material storage station, the first connection The shaft and the second connecting shaft are connected by a synchronous belt assembly, and a synchronous pulley is arranged at the end or middle of the first connecting shaft and the second connecting shaft, and a synchronous belt is arranged between the two synchronous pulleys, so that the first The connecting shaft and the second connecting shaft realize synchronous rotation; the first conveyor belt in the first lifting transmission assembly is a chain, and correspondingly, the first transmission wheel is a sprocket. (2) In the second lifting mechanism on the pallet backup station, the fourth connecting shaft and the fifth connecting shaft are also connected by a synchronous belt assembly, respectively at the end or middle of the fourth conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com