A kind of pretreatment method and system of starch size

A starch slurry and pretreatment technology, applied in the field of starch treatment, can solve the problems of wasting chemical raw and auxiliary materials, increasing the difficulty of sewage treatment, reducing starch reaction efficiency, etc., achieving convenient control, saving raw material costs, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

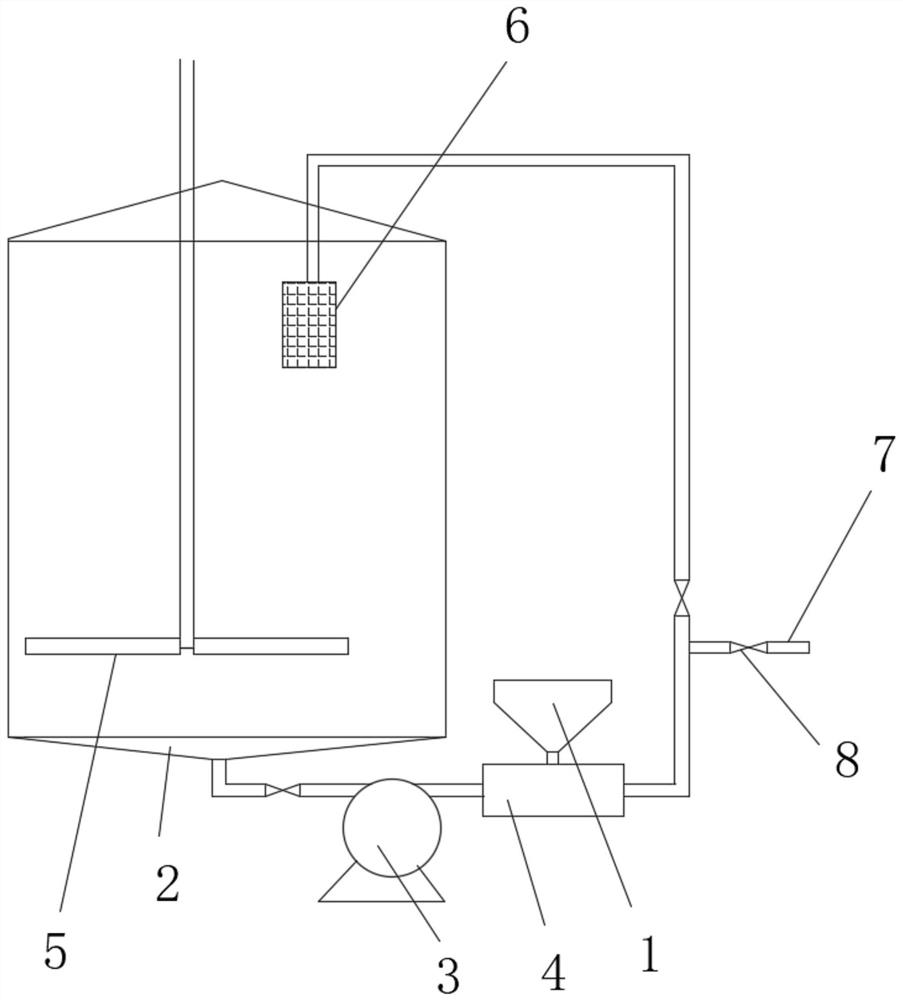

[0034] Such as figure 1 Shown, a kind of pretreatment method of starch slurry comprises the steps:

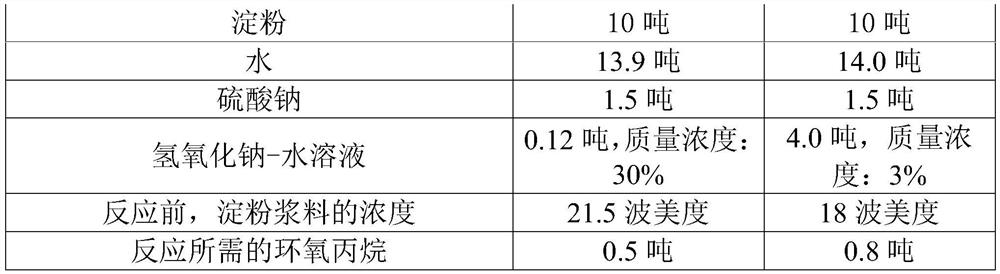

[0035] (A1), take by weight 10 parts of starch, 13.9 parts of water, 0.12 parts of a strong alkali-water solution with a mass concentration of 30%, and set aside;

[0036] (A2), add water and strong alkali-water solution in feeding tank 1 and mix evenly, obtain mixed solution;

[0037] (A3), add the starch that accounts for 40% of the total amount of starch in the step (A1) to the mixed solution obtained in the step (A2) via the feeding tank 1, add the remaining starch after mixing evenly, and then stir evenly, that is Obtain starch slurry.

[0038] The starch is native tapioca starch.

[0039] The step (A2) also includes: before adding water and strong alkali-water solution into the feeding tank 1, cleaning the feeding tank 1 until there is no starch residue.

[0040] In the step (A3), keep the temperature of the mixed solution at 25°C.

[0041] The strong base-water solu...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is:

[0049] Such as figure 1 Shown, a kind of pretreatment method of starch slurry comprises the steps:

[0050] (A1), take by weight 8 parts of starch, 10 parts of water, 0.1 part of a strong alkali-water solution with a mass concentration of 28%, and set aside;

[0051] (A2), add water and strong alkali-water solution in feeding tank 1 and mix evenly, obtain mixed solution;

[0052] (A3), add the starch that accounts for 20% of the total amount of starch in the step (A1) to the mixed solution obtained in the step (A2) through the feeding tank 1 at one time, add the remaining starch after mixing evenly, and then stir evenly, that is Obtain starch slurry.

[0053] In the step (A3), keep the temperature of the mixed solution at 10°C.

[0054] In the step (A2), after adding water and a strong alkali-water solution, add 1 part by weight of sodium sulfate to the feeding tank 1.

Embodiment 3

[0056] The difference between this embodiment and embodiment 1 is:

[0057] Such as figure 1 Shown, a kind of pretreatment method of starch slurry comprises the steps:

[0058] (A1), take by weight 12 parts of starch, 16 parts of water, 0.14 parts of strong alkali-water solution with a mass concentration of 32%, and set aside;

[0059] (A2), add water and strong alkali-water solution in feeding tank 1 and mix evenly, obtain mixed solution;

[0060] (A3), add the starch that accounts for 80% of the total amount of starch in the step (A1) to the mixed solution obtained in the step (A2) via the feeding tank 1, add the remaining starch after mixing evenly, and then stir evenly, that is Obtain starch slurry.

[0061] In the step (A3), the temperature of the mixed solution was kept at 32°C.

[0062] In the step (A2), after adding water and a strong alkali-water solution, add 2 parts by weight of sodium sulfate to the feeding tank 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com