A special sliding waste engine oil recovery device for automobiles

A recovery device and sliding technology, which is applied in the installation/connection of lubricant purification devices, lubricating parts, pressure lubricants, etc., can solve the problems of waste engine oil turbidity, pollution, high viscosity, etc., and reduce the time for cleaning the ground , reduce the workload, the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

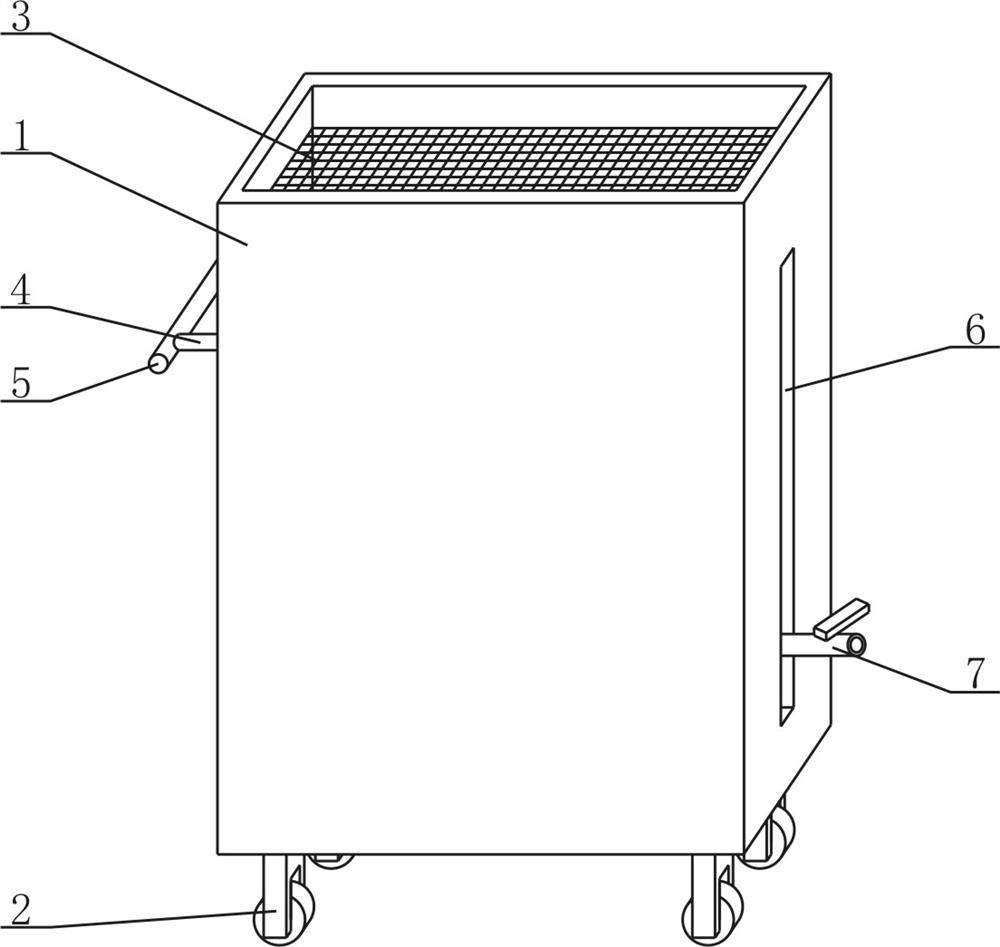

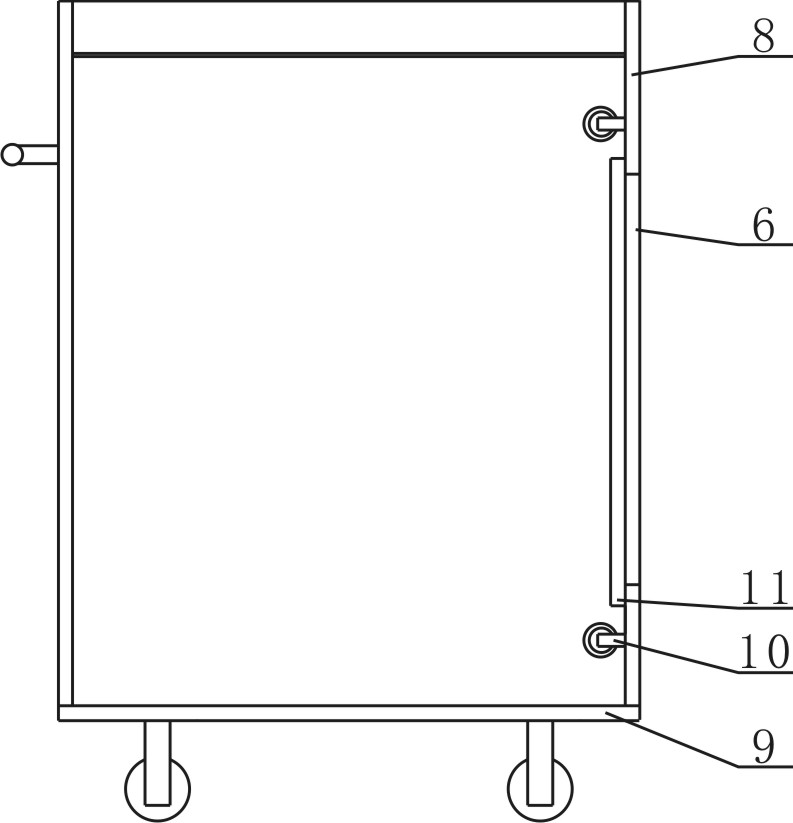

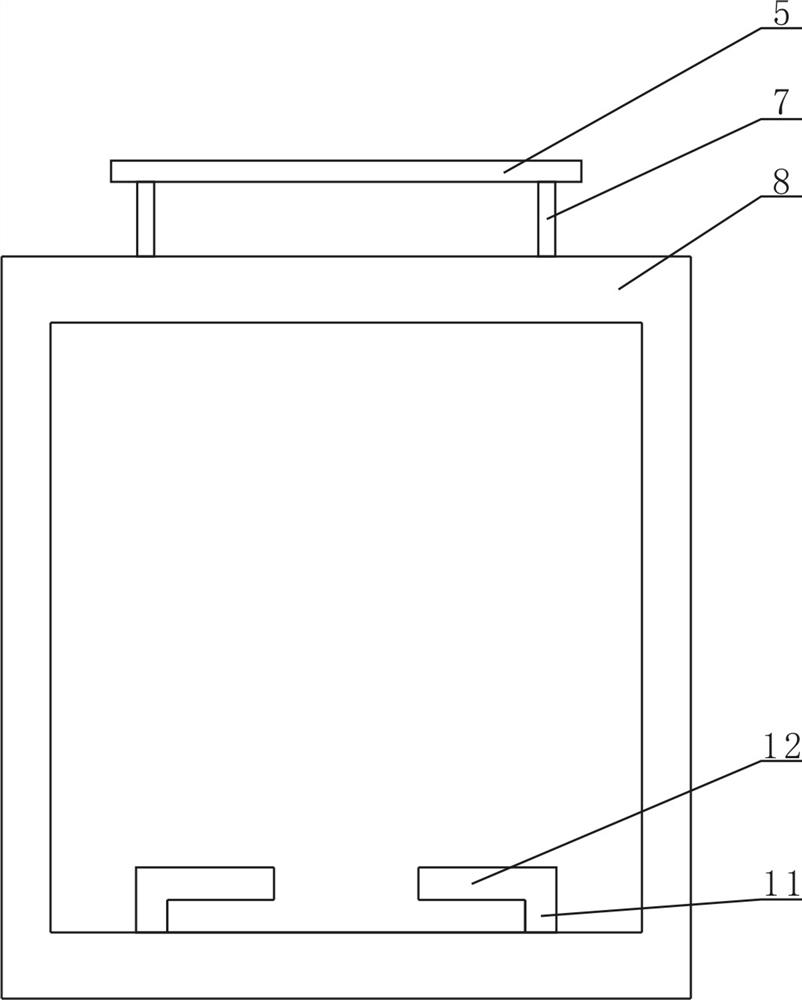

[0024] combined with Figure 1~5 A sliding type waste engine oil recovery device for automobiles, comprising a holding cylinder 1, wheels 2, connecting rod 4, grip rod 5, isolation net 3, fixing device, rotating device, fixing belt 15 and valve 7, on the holding cylinder 1 Be provided with wheel 2 and connecting rod 4, be provided with isolation net 3, rotating device and fixing device in the holding tube 1, be provided with handle bar 5 on the connecting rod 4, be provided with fixing band 15 on the fixing device, set on the fixing band 15 Valve 7 is arranged, and fixing device is made of connecting plate 11 and fixing plate 12, and connecting plate 11 is provided with fixing plate 12, and rotating device is made of fixing rod 10, rotating shaft 13 and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com