Classified recycling treatment method for medical injection and puncture instruments

A technology for recycling and processing syringes, applied in the medical field, can solve the problems of damage to the structure of the metal needle tube, waste of production processes, etc., and achieve the effects of rapid separation, complete separation, and avoidance of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

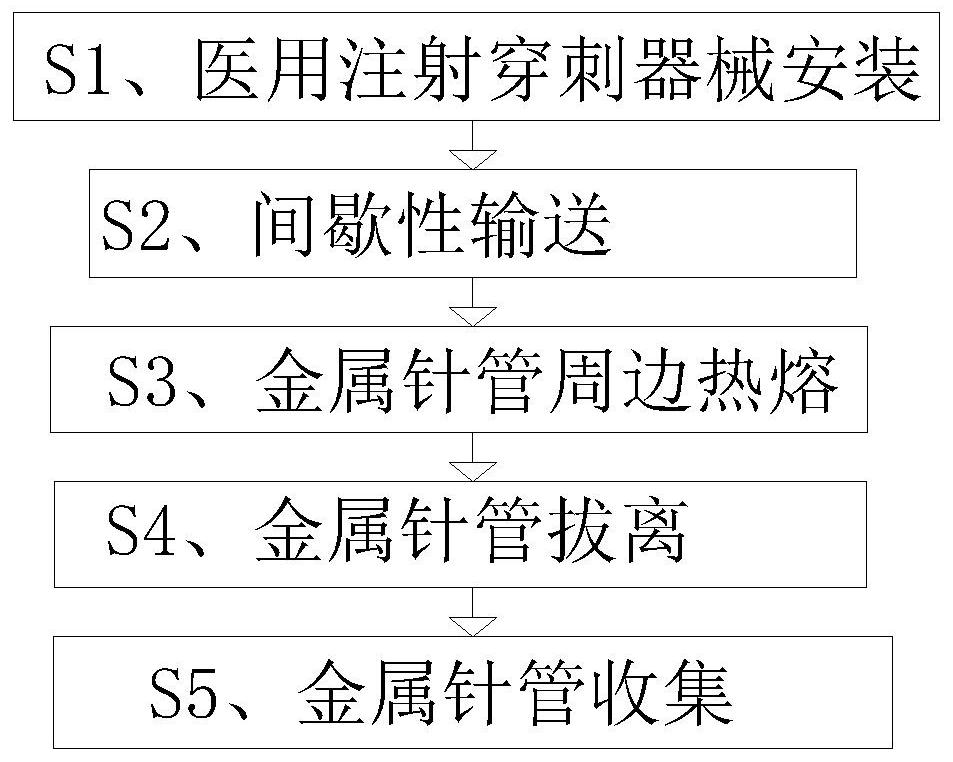

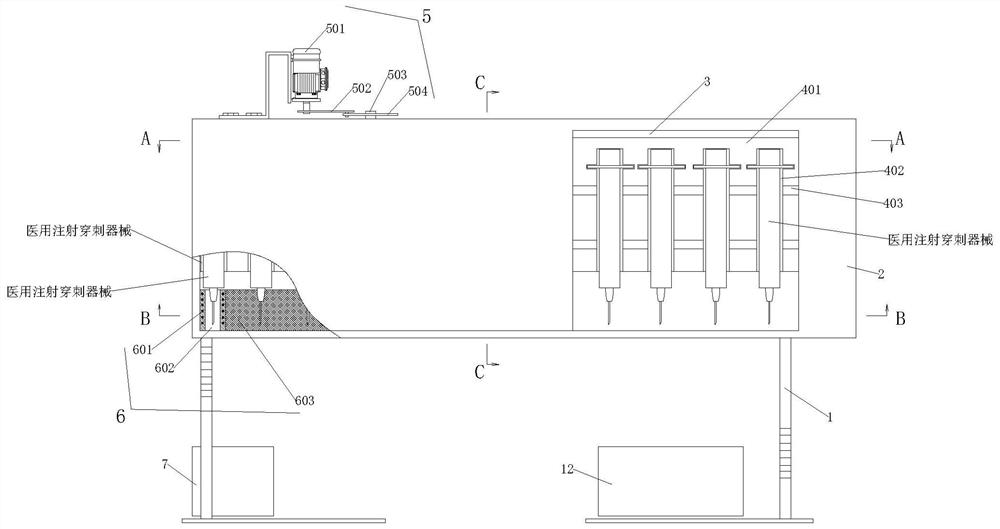

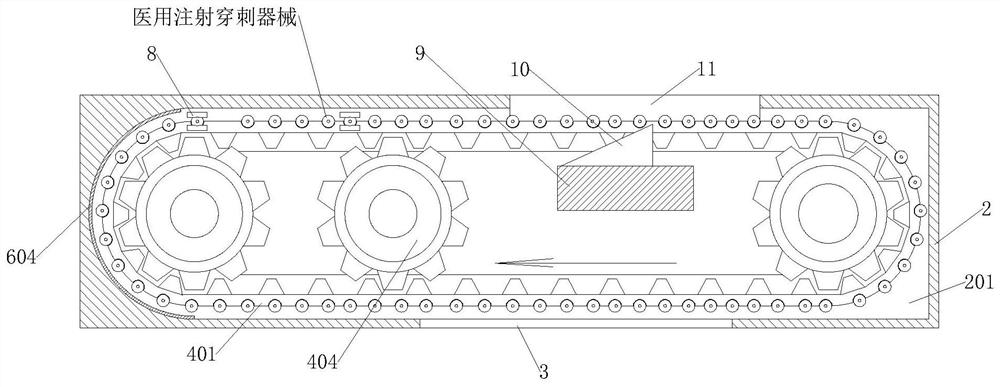

[0053] see Figure 1-10 It is a schematic diagram of the overall structure of a sorting recovery treatment method for medical injection puncture instruments;

[0054] A sorting and recycling treatment method for medical injection puncture instruments, comprising the following steps:

[0055] S1. Installation of medical injection puncture instruments: fix and install the recovered medical injection puncture instruments on the conveyor belt at equal intervals according to a certain interval;

[0056] S2. Intermittent delivery: intermittent delivery and transfer of the medical injection puncture instruments fixed at equal intervals in step S1;

[0057] S3. Heat melting around the metal needle tube: heat-melt the metal needle tube periphery at the bottom of the medical injection puncture device intermittently transported in step S2, transfer through intermittent transport, and use the arc transfer of the conveyor belt to make the bottom of the medical injection puncture device M...

Embodiment 2

[0074] see Figure 1-10 It is a schematic diagram of the overall structure of a sorting recovery treatment method for medical injection puncture instruments;

[0075] A sorting and recycling treatment method for medical injection puncture instruments, comprising the following steps:

[0076] S1. Installation of medical injection puncture instruments: fix and install the recovered medical injection puncture instruments on the conveyor belt at equal intervals according to a certain interval;

[0077]S2. Intermittent delivery: intermittent delivery and transfer of the medical injection puncture instruments fixed at equal intervals in step S1;

[0078] S3. Heat melting around the metal needle tube: heat-melt the metal needle tube periphery at the bottom of the medical injection puncture device intermittently transported in step S2, transfer through intermittent transport, and use the arc transfer of the conveyor belt to make the bottom of the medical injection puncture device Mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com