Structural part and overload protection mechanism of torque measuring device

A technology of torque measurement and overload protection, which is applied in the direction of measuring devices, torque measurement, power measurement, etc., can solve the problems of high precision machining of coaxial holes, lack of protection of strain bodies, difficulty in uniform spacing control, etc., to achieve The effect of improving service life, improving accuracy and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

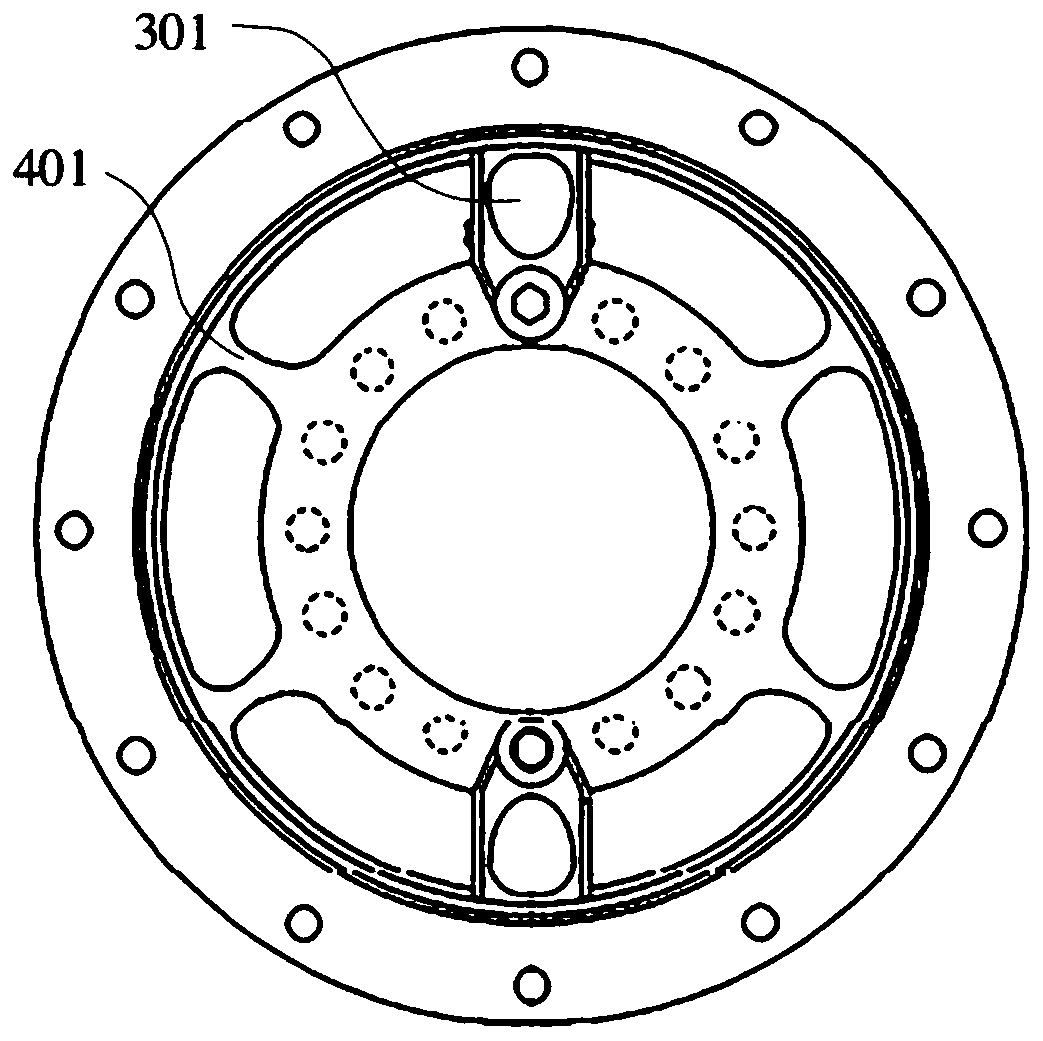

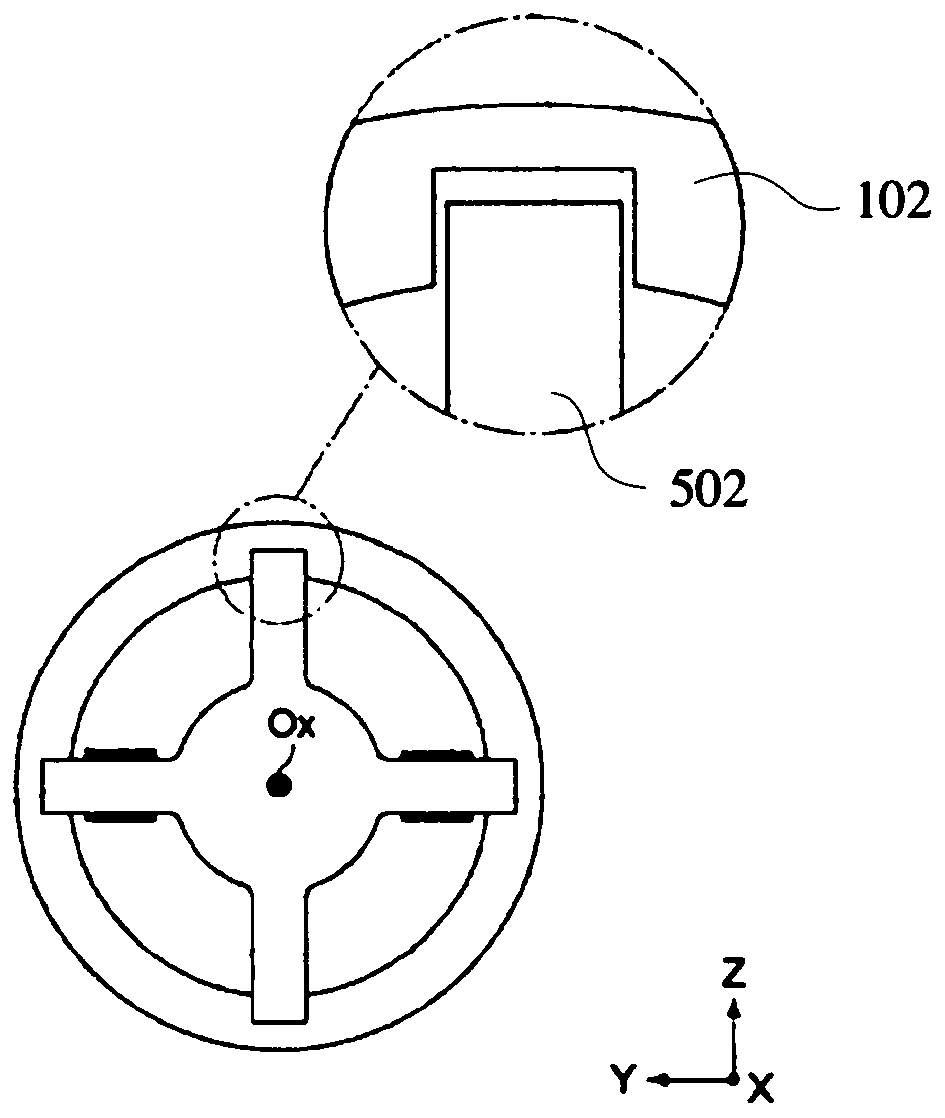

Embodiment 1

[0084] The structure of this embodiment is Figure 5 As described, the anti-bending moment connecting portion is a straight connecting piece 410, and the straight connecting piece 410 may also be called a connecting beam. The structure is composed of an outer ring 110, an inner ring 210, a strain body 310 and a straight connecting piece 410. The above-mentioned components are obtained by integral processing and molding of the same material. In order to improve the rigidity of the robot against bending moment, the straight connecting piece 410 is processed by wire cutting or laser cutting. The outer ring 110 and the inner ring 210 are concentric circles, and the gap between the two is roughly a circular ring. The straight connecting piece 410 connects the outer ring 110 and the inner ring 210, that is, the straight connecting piece 410 is arranged on the outer ring 110 and the inner ring 210. The gap position. The distribution requirement of the straight connecting member 410 i...

Embodiment 2

[0092] The function of the anti-bending moment connection part is to resist the bending moment. It is required that the size in the axial direction of the structural member is as large as possible, that is, as "thick" as possible, so that it has higher bending rigidity; and in the other direction, it is required It reduces the impact on the measured torque as much as possible, that is, it is required that the bending moment connection part is as thin as possible in this direction; this is a contradiction. Moreover, it is not only difficult to process the bending moment-resistant connection part to be very thin, but also has the risk of fracture. Under the processing conditions of acceptable cost, the minimum thickness of the bending moment connection part is about 0.5mm.

[0093] In order to solve the above contradiction, such as Picture 10 As shown, the anti-bending moment connecting portion is processed into a folding connecting piece 420 connected between the outer ring 110 a...

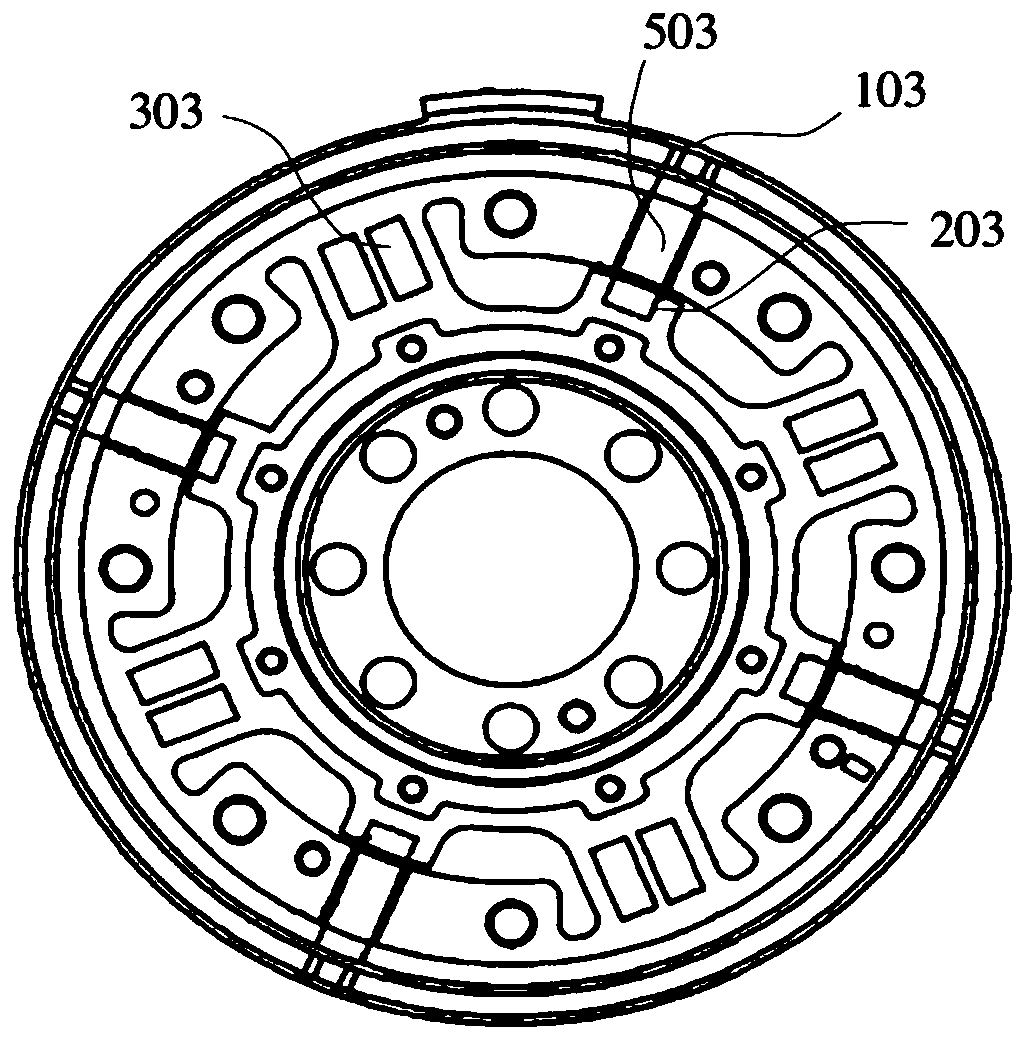

Embodiment 3

[0095] Such as Picture 11 versus Picture 12 As shown, this embodiment is another alternative to improve the bending moment resistance of the torque measuring device. A detachable connector 430 is added between the outer ring 110 and the inner ring 210. One end of the body 431 of the connector 430 is fixed to the outer ring 110 by a screw 433, the other end of the body 431 is mounted with a roller 432, and the shaft of the roller 432 is mounted on the Inside the body 431. The rolling surface of the roller 432 is in contact with a surface of the inner ring 210, which can appropriately increase the preload contact force. The axis of the roller 432 extends along the radial direction of the inner ring, that is, the axis of the roller 432 and the rotation axis of the torque measuring device are perpendicular and intersect. When the outer ring 110 and the inner ring 210 move relative to each other due to torque, the roller 432 rolls on the surface of the inner ring 210 without affe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com