Formation method of nickel-metal hydride battery

A chemical formation method and nickel-metal hydride battery technology, which is applied in the charging/discharging of nickel storage batteries, alkaline storage batteries, secondary batteries, etc., can solve the problems of not considering the impact of battery performance as a whole, increasing battery internal resistance, and deteriorating battery performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

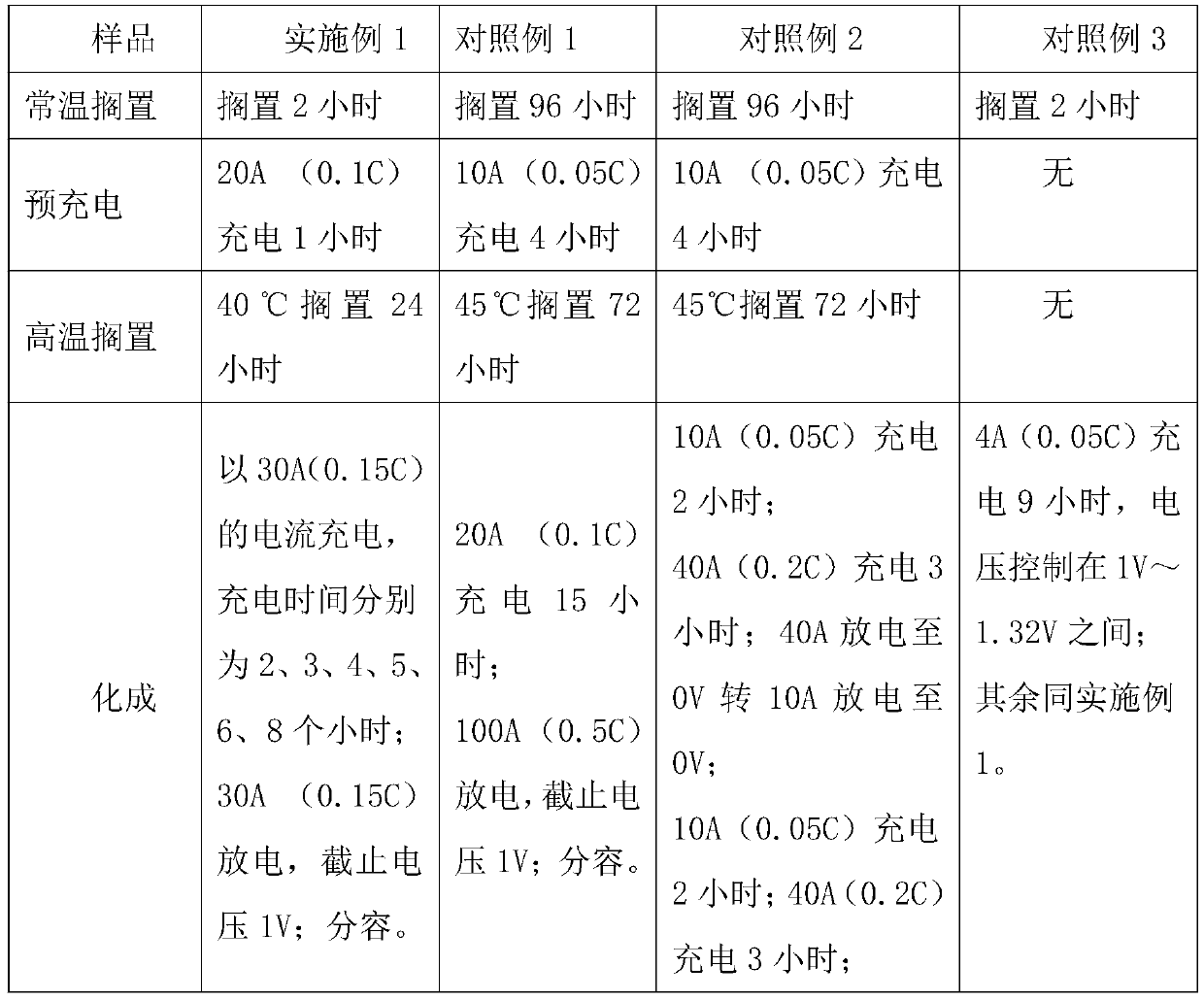

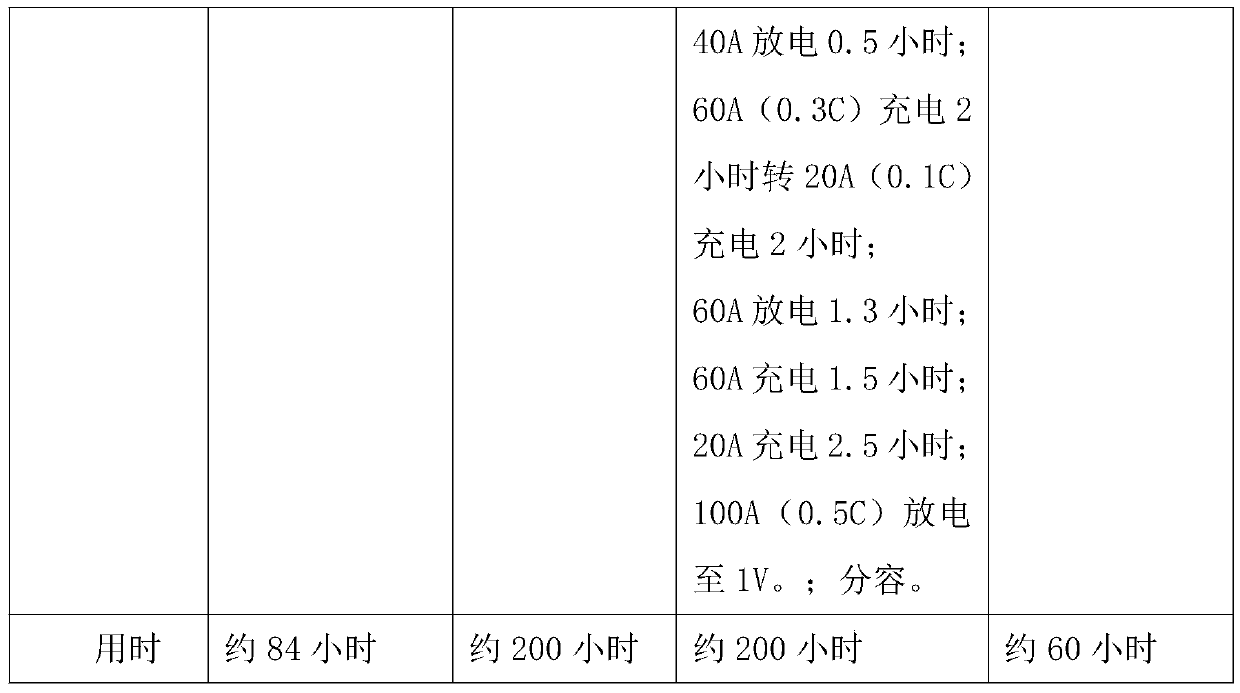

[0019] A method for forming a nickel-hydrogen battery, the steps of which are:

[0020] (1) Leave the injected battery at room temperature for 1 to 5 hours, and then charge it with a current of 0.1C for 1 hour;

[0021] (2) Place the charged battery in a dry oven, set the oven temperature to 40°C, and leave it for 24 hours;

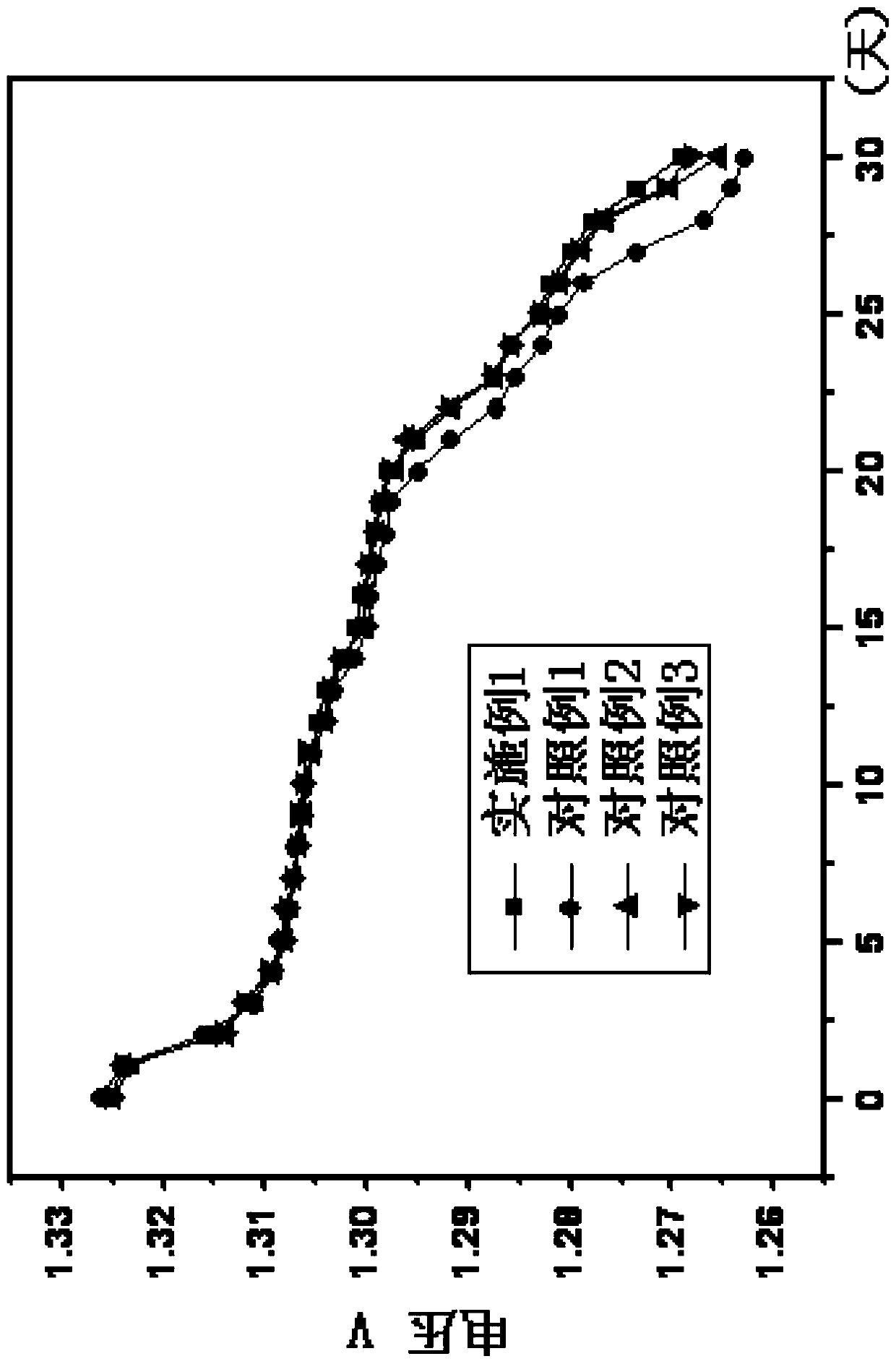

[0022] (3) Take the battery out of the drying oven and put it on hold at 25°C±5°C until the battery case cools down to room temperature. Then discharge with a current of 0.15C, the discharge cut-off voltage is 1V; after emptying the battery, charge and discharge the battery with a current of 0.15C, the charging time is 2, 3, 4, 5, 6, 8 Hours, the discharge cut-off voltage is set to 1V; finally, charge with a current of 0.5C for 0.6 hours, and put it aside for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com