Prefabricated wall greening planting container and wall greening method

A prefabricated assembly and wall greening technology, applied in the field of building decoration, can solve the problems of inability to industrialize the greening method, small greening area and high greening cost, and achieve the effect of saving the layout of irrigation pipes, easy construction and easy post-maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

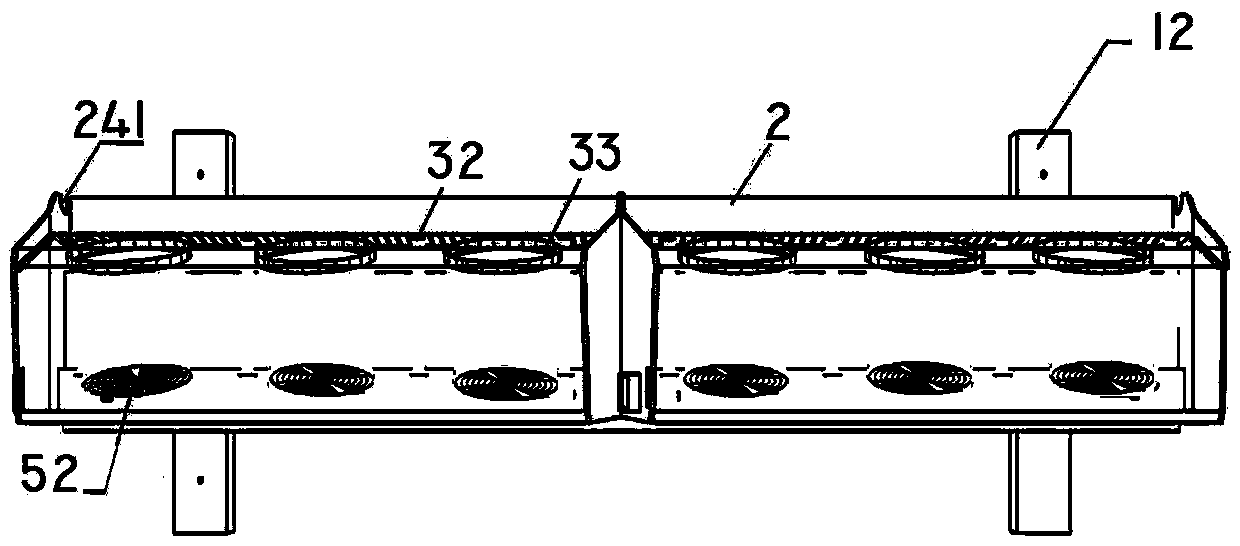

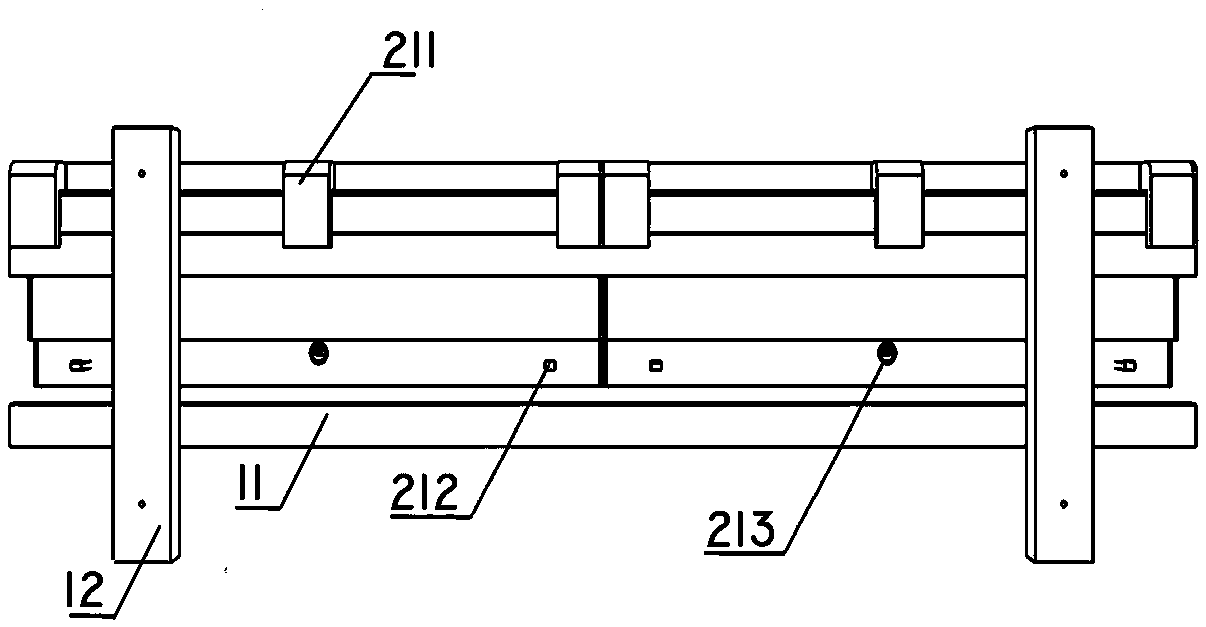

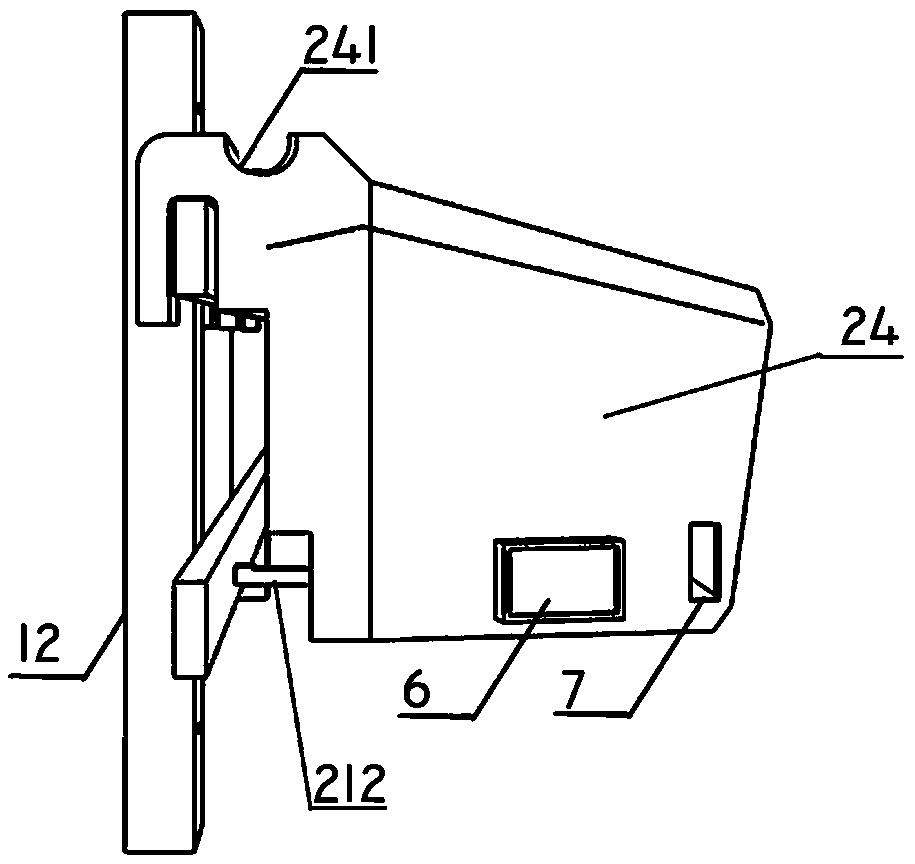

[0058] Such as figure 1 with Figure 4 As shown, one aspect of the present invention provides a prefabricated wall greening planting container with simple structure, controllable cost and easy later maintenance, including a wall structure 1, a planting box body 2 and a planting box body arranged in the planting box body 2 planting module. Such as Figure 12 with Figure 13 As shown, the connecting wall structure 1 is in the shape of a well, including a transverse secondary keel 11 and a vertical main keel 12, and the connecting wall structure 1 and the wall are connected by expansion bolts. The transverse secondary keel 11 and the vertical main keel 12 can be steel bars with a length of 300 mm and a width of 50 mm and a length of 1050 mm and a width of 30 mm. The top and bottom of the vertical main keel 12 are respectively reserved with holes for expansion bolts. The greening planting container can be quickly assembled and spliced at a designated site, and the installatio...

Embodiment 2

[0075] Embodiment 2, the prefabricated wall greening planting container and wall greening method, is the same as Embodiment 1, except that the planting module is a multi-slot modular container 5 . Such as Figure 11 As shown, the multi-slot module includes at least three cylindrical planting buckets 51 with a diameter of 90 mm. A support block 52 is provided at the center of the lower end surface of the bottom plate of the planting bucket 51; a circular hollow is arranged on the bottom plate of the planting bucket 51. The spacing between the shape cutouts is 5mm. The diameter of the bottom surface of the supporting block 52 is 8mm, and the height is 10mm. The top of the planting barrel 51 is provided with an edge sunken groove design extending outward by 5mm and recessed downward by 7mm. The distance between adjacent planting barrels 51 is 60mm.

[0076] The prefabricated and assembled wall greening planting container and the wall greening method provided by the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com