Protection joint of steel beam on outer wall of fabricated steel structure building

A technology for building exterior walls and steel structures, applied to truss structures, buildings, building components, etc., can solve problems such as lack of a relatively complete solution, and achieve the effects of fast construction, simple and clear structure, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

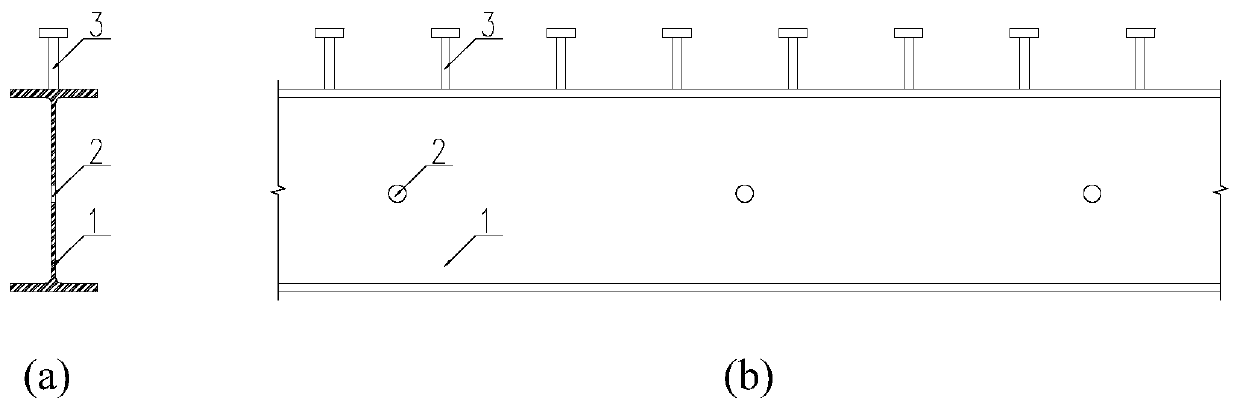

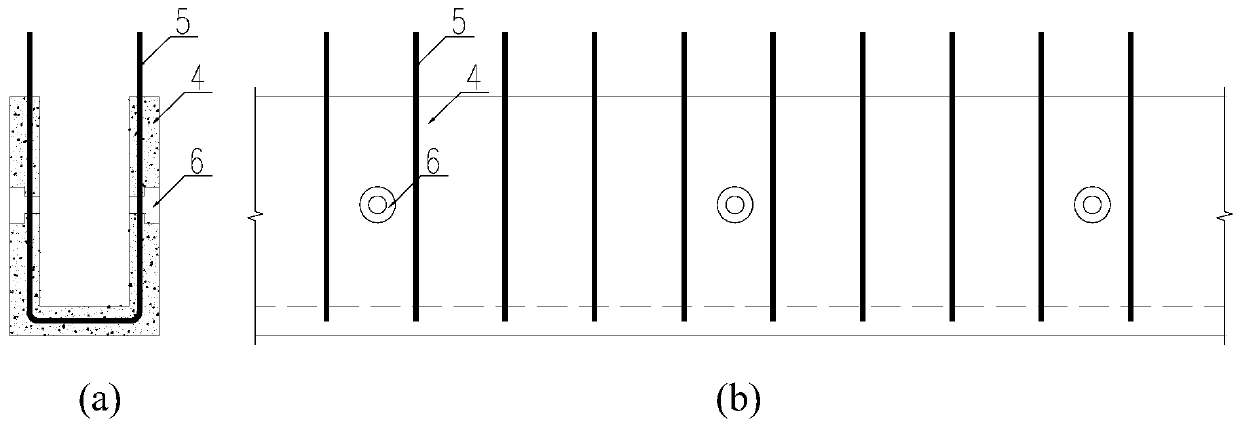

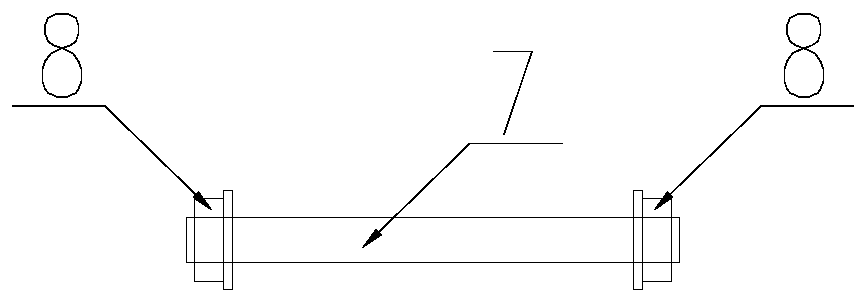

[0032] like Figure 4 As shown, it includes an H-shaped steel beam 1, a stud 3, a precast concrete U-shaped plate 4, a steel bar 5, and an opposite screw 7.

[0033] like figure 2 As shown, the precast concrete U-shaped plate 4 has a U-shaped section and the U-shaped opening is upward, and the precast concrete U-shaped plate 4 is embedded with the same U-shaped steel bar 5. The two ends of the steel bars 5 penetrate upwards out of the precast concrete U-shaped slab 4 and the top surface extends into the concrete floor slab 9, and the U-shaped steel bar 5 protrudes from the upper end of the precast concrete U-shaped slab 4 for a certain distance. The upper end surface of the concrete U-shaped slab 4 is in close contact with the bottom surface of the concrete floor slab 9; an H-shaped steel beam 1 is installed in the middle of the prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com