Lifter automatic welding system

An automatic welding and lifting technology, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems such as welding of parts that cannot be lifted, to improve clamping efficiency, easy to operate, and save auxiliary working time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

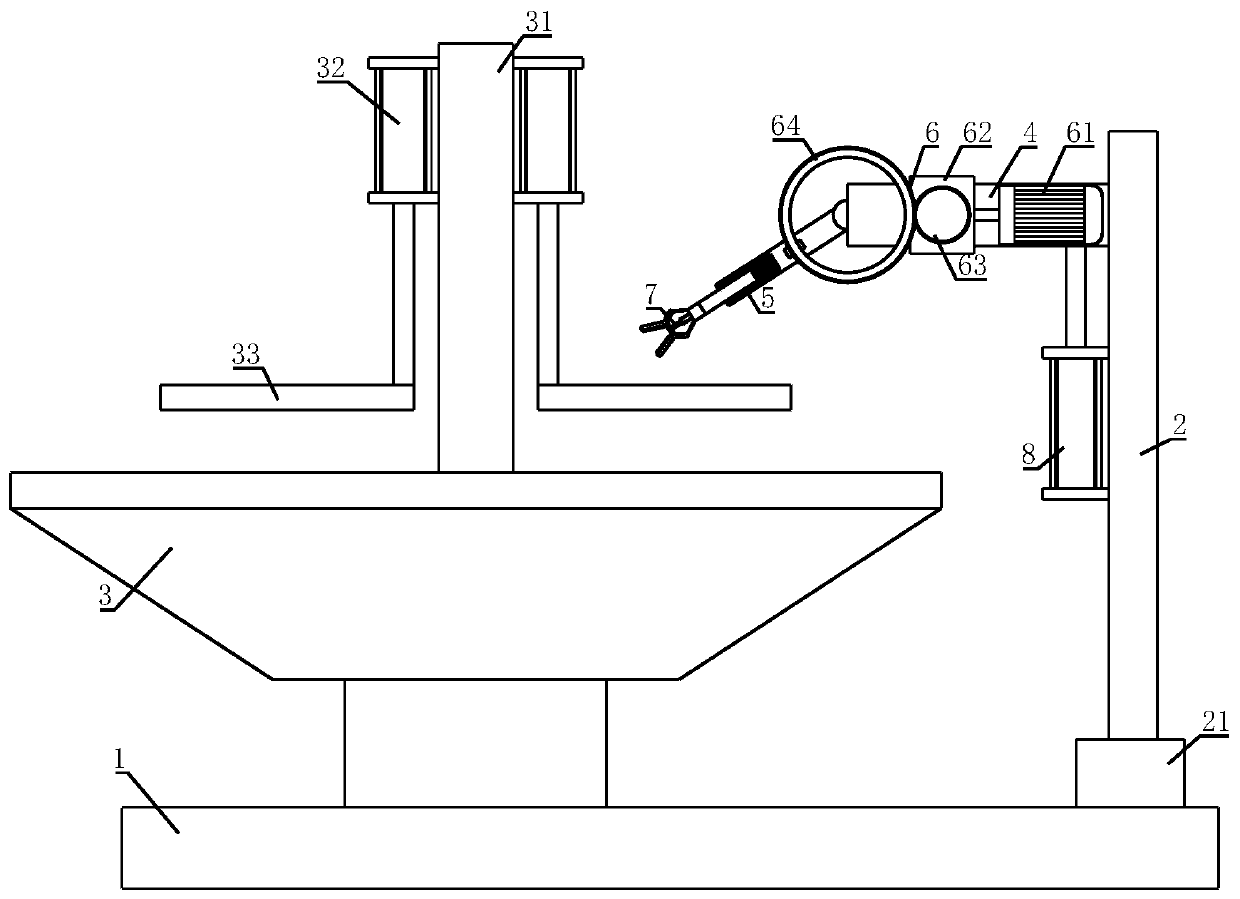

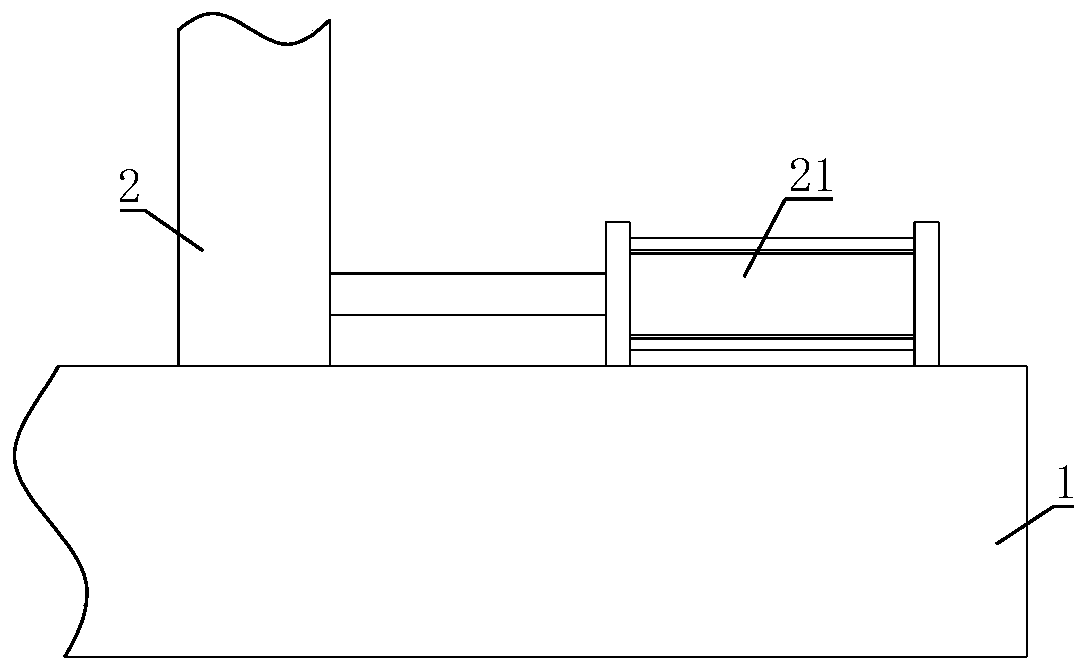

[0027] Such as figure 1 , figure 2 As shown, an automatic welding system for an elevator is characterized in that it includes a base 1, a slide groove is provided on the base 1, a bracket 2 is sleeved in the slide groove, and a traverse cylinder 21 for driving the movement of the bracket 2 is installed on the base 1. , The piston rod of the traverse cylinder 21 is fixed to the bracket 2. The base 1 is also installed with a welding table 3, the bracket 2 is installed with a lifting frame 4, the other end of the lifting frame 4 is hinged with a tilting mechanism 5, and the lifting frame 4 is installed There is a driving mechanism 6 for driving the tilting mechanism 5 to tilt, the other end of the driving mechanism 6 is connected with the tilting mechanism 5; the other end of the tilting mechanism 5 is connected with a clamping mechanism 7 for clamping the welding rod; on the welding table 3 A fixing frame 31 is installed, a pressing cylinder 32 is installed on the fixing frame 31...

Embodiment 2

[0030] On the basis of the first embodiment, the driving mechanism 6 includes a bidirectional motor 61, the output shaft of the bidirectional motor 61 is connected with a reducer 62, the bidirectional motor 61 and the reducer 62 are both installed on the lifting frame 4, the output of the reducer 62 A driving gear 63 is connected to the shaft, a driven gear 64 is fixed on the tilting mechanism 5, and the driving gear 63 meshes with the driven gear 64.

[0031] The driving mechanism 6 includes a bidirectional motor 61. After the bidirectional motor 61 is started, the reducer 62 drives the driving gear 63 to rotate, and the driving gear 63 drives the driven gear 64 on the tilting mechanism 5 to rotate, and the tilting mechanism 5 tilts accordingly, and the electrode The angle of inclination is adjusted to facilitate the welding rod to extend into the hidden position of the workpiece.

Embodiment 3

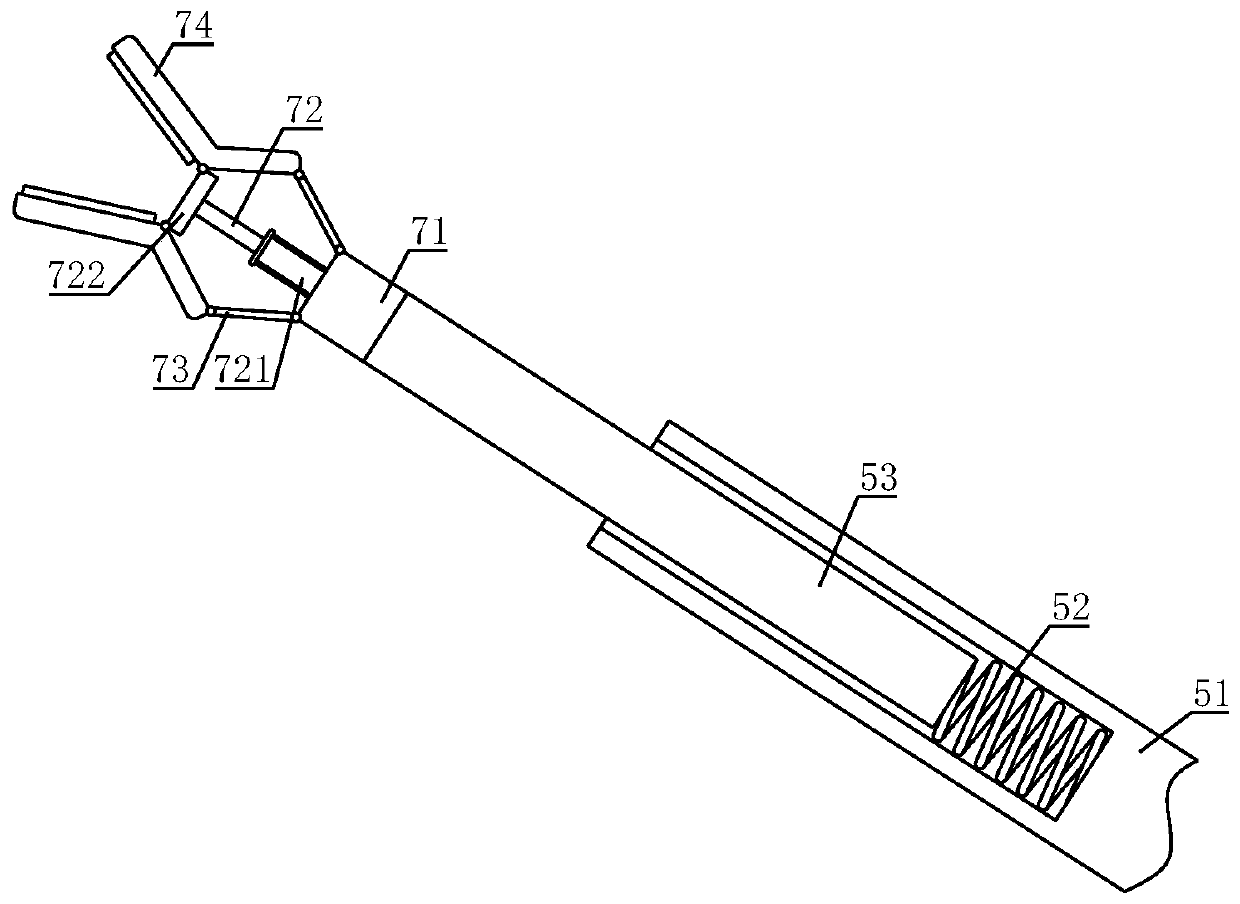

[0033] Such as image 3 As shown, on the basis of Embodiment 1 or Embodiment 2, the clamping mechanism 7 includes a fixing block 71, one end of the fixing block 71 is connected with the tilting mechanism 5, and the other end of the fixing block 71 is respectively connected with a stretching assembly 72 and two rockers 73, the stretching assembly 72 is fixed with the fixed block 71, the rocker 73 is hinged with the fixed block 71, the other end of the rocker 73 is hinged with a clamping claw 74, the middle of the two clamping claws 74 are respectively connected with One end of the stretching assembly 72 away from the fixed block 71 is hinged.

[0034] The rocker 73, the clamping claw 74, and the stretching assembly 72 form a rocker slider mechanism. When the stretching assembly 72 is retracted, the two clamping claws 74 rotate toward each other under the pulling of the stretching assembly 72, so that the two clamping claws 74 can clamp the welding rod, which realizes the rapid cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com