Preparation device for rubber and plastic mixed high-flame-retardance thermal insulation materials

A thermal insulation and preparation device technology, which is applied in the field of rubber-plastic blended high flame-retardant thermal insulation materials, can solve the problems of insufficient mixing, poor preparation effect, and high operating costs, so as to prevent uneven foaming and accelerate feeding The speed and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

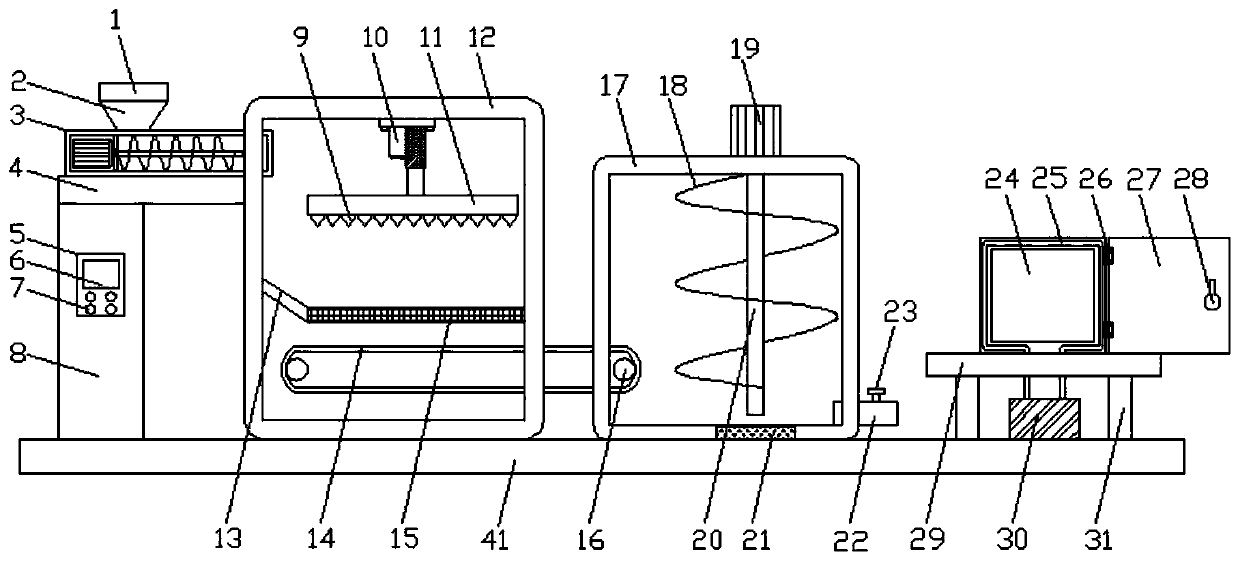

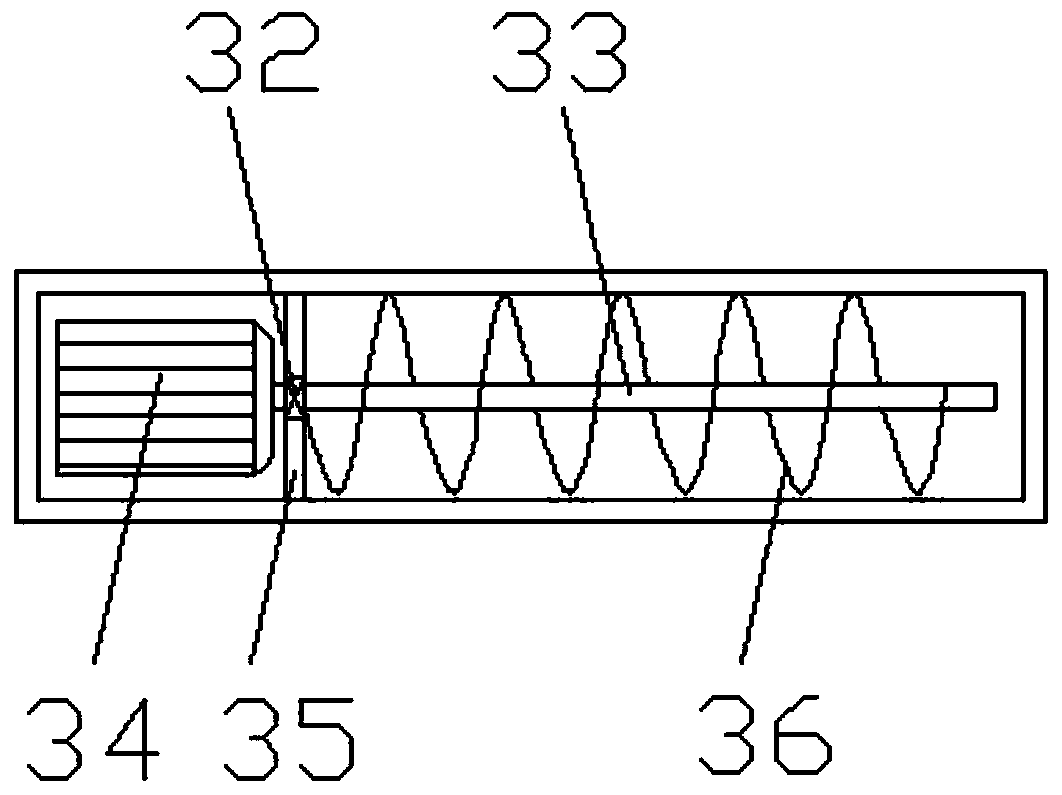

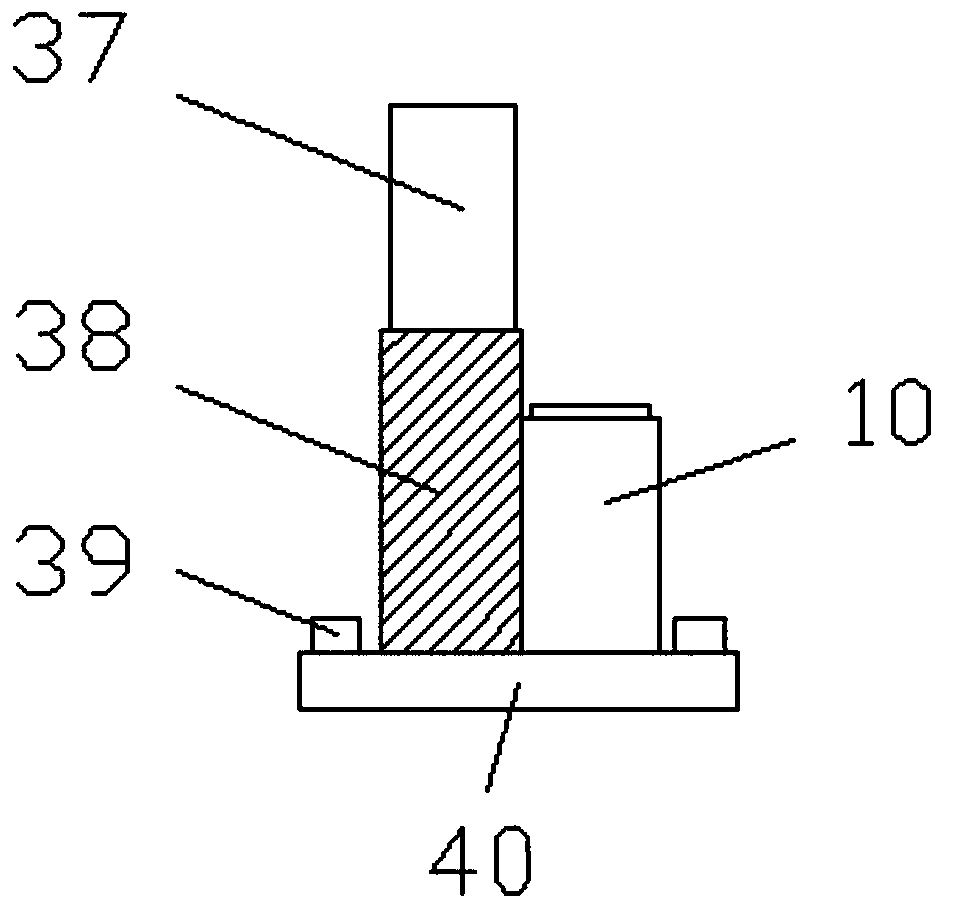

[0025] see Figure 1-3 According to an embodiment of the present invention, a preparation device for a rubber-plastic blended high flame-retardant thermal insulation material includes a crushing chamber 12, a heating chamber 17, and a cooling chamber 24. The top of the crushing chamber 12 is provided with a lifting motor 10, so One side of the lifting motor 10 is provided with a moving plate 11, the bottom of the moving plate 11 is welded with sawtooth 9, and the sawtooth 9 is multiple, and the bottom of the sawtooth 9 is provided with a screen 15, and one of the screen 15 is The side is connected with a slide plate 13, the other end of the slide plate 13 is welded to the inner wall of the crushing chamber 12, a heating chamber 17 is provided on one side outside the crushing chamber 12, a conveyor belt 14 is provided at the bottom of the screen 15, and the Bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com