Complete equipment using zero-valent iron to reduce and couple microorganisms to prepare Schwertmannite

A technology of Schwittmannite and complete sets of devices, applied in the field of environmental engineering, can solve the problems of cost, low amount of synthetic minerals in batches, low total iron precipitation rate, etc., achieves easy operation, improves mineral production efficiency, and maintains ore-forming rate. and lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

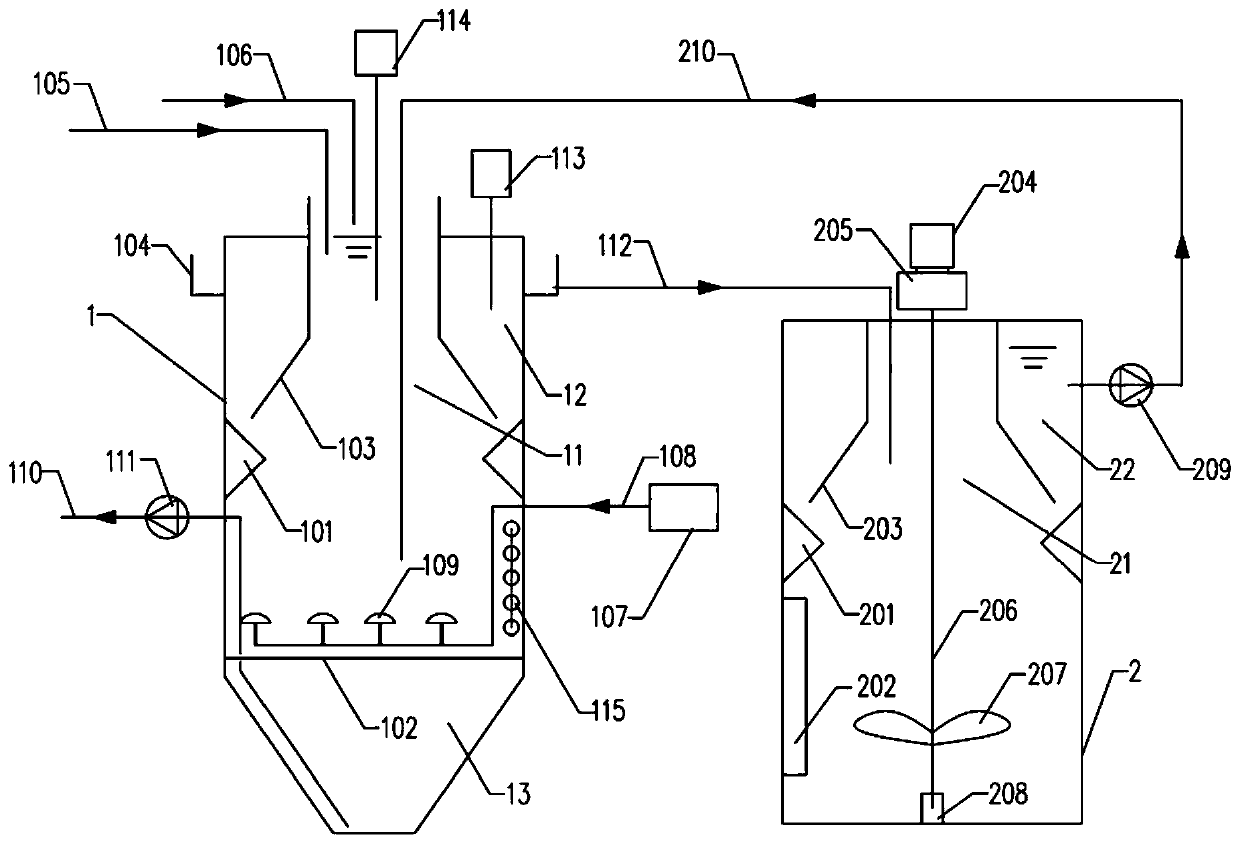

[0035] According to the complete set of equipment mentioned in the present invention, this embodiment establishes a set of complete set of equipment for preparing Schwittmannite minerals based on zero-valent iron reduction coupling microorganisms, as shown in the attached figure 1 shown.

[0036] In this embodiment, the total amount of the mixed solution is 1500L (but not limited thereto), wherein the volume of the mixed solution in the biological oxidation unit 1 is 1200L, the volume of the mixed solution in the reduction unit 2 is 300L, and the total system hydraulic retention time (HRT) is 3 days.

[0037] Bio-oxidation unit 1 is inoculated with 2×10 8 A. ferrooxidans LX5 bacterial broth, initial FeSO 4 ·7H 2The zero concentration is 22.24g / L, and the pH value is 2.1-2.3. The blower 107 continuously aerates and supplies oxygen in the biological oxidation unit 1, so that the Fe in the biological oxidation unit 1 2+ Oxidation occurs under the action of microorganisms, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com