Method for preparing light-duty composite artificial stone profiles using yellow phosphorus slag

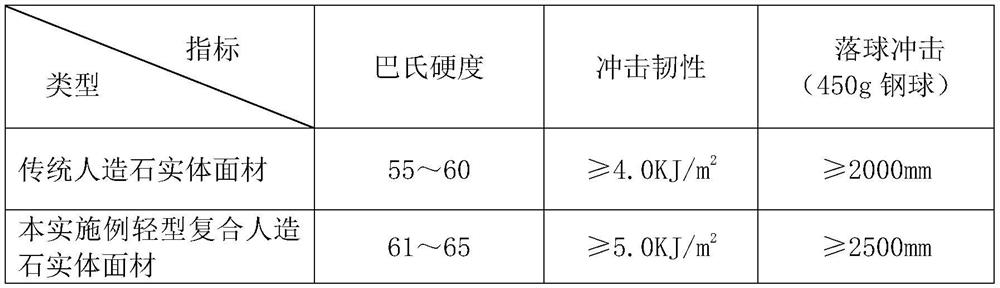

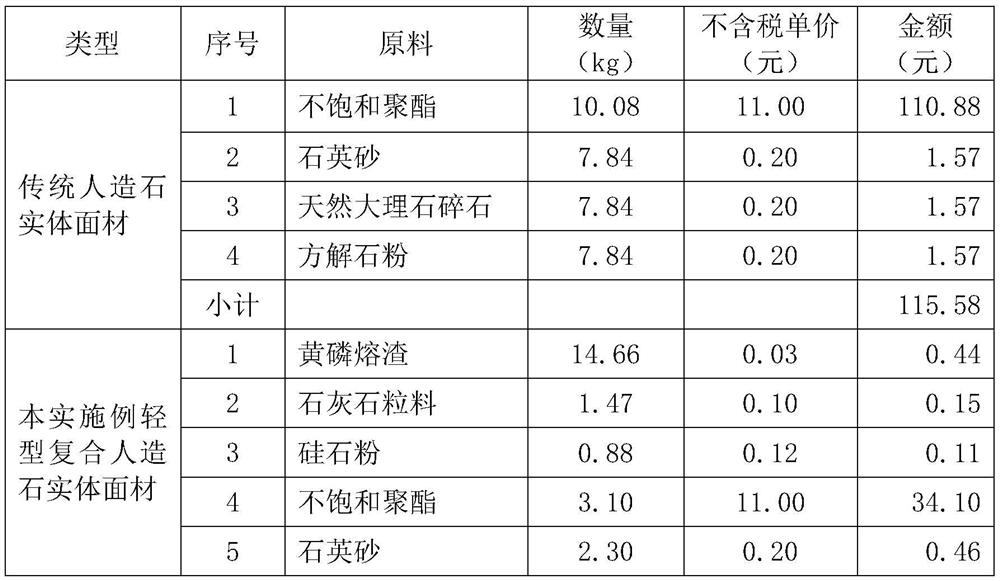

An artificial stone and slag technology, applied in the fields of metallurgy, chemical industry and building materials, can solve problems such as visual pollution and environmental pollution, and achieve the effects of reducing specific gravity, solving easy peeling, and promoting cyclic clean production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

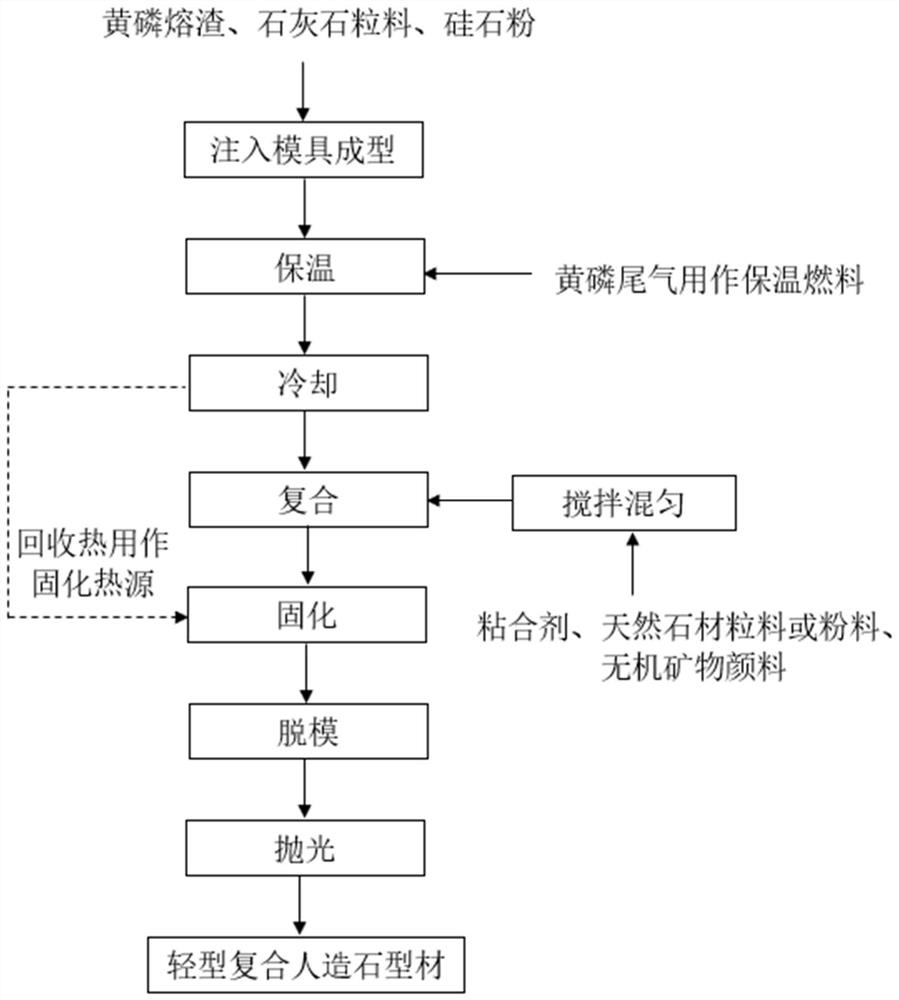

[0026] see figure 1 Shown, the specific embodiment that the present invention provides is as follows:

[0027] The method of using yellow phosphorus slag to prepare light-duty composite artificial stone profiles in this embodiment, the method includes:

[0028] S1. Preparation of air-porous base layer: mix silica powder and limestone granules and evenly arrange them on the bottom of the base-layer forming mold, then pour yellow phosphorus slag into the base-layer forming mold, and make the air-hole base layer profile after heat preservation, cooling and cutting processes ; Among them, the base forming mold is made of materials resistant to 1600 ° C or above, such as mullite shed board;

[0029]S2. Preparation of surface layer and molding of light-duty composite artificial stone profiles, mixing and stirring the adhesive with natural stone granules or powders, and inorganic mineral pigments to obtain a mixture, and putting the pore-based base profile into the bottom of the art...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com