Method for synthesizing ortho-amino aromatic ketone from aromatic carboxylic acid

A technology for amino aromatic ketones and aromatic carboxylic acids, which is applied in the preparation of carboxylic acid nitriles, chemical instruments and methods, and the preparation of organic compounds. It can solve problems such as poor functional group compatibility, harsh reaction conditions, and excessive acylating reagents. Residue, the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

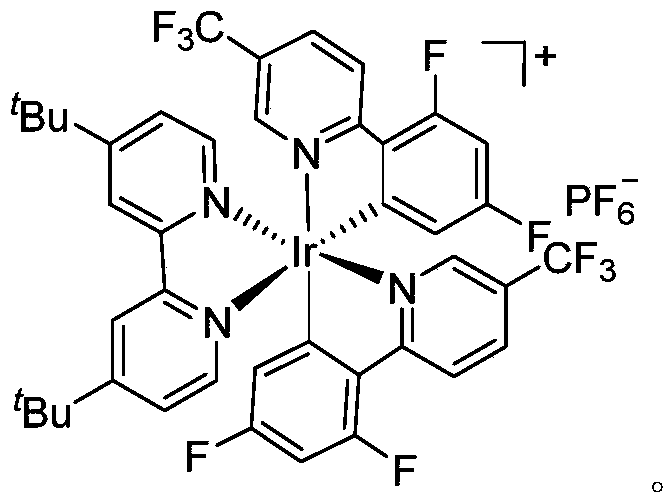

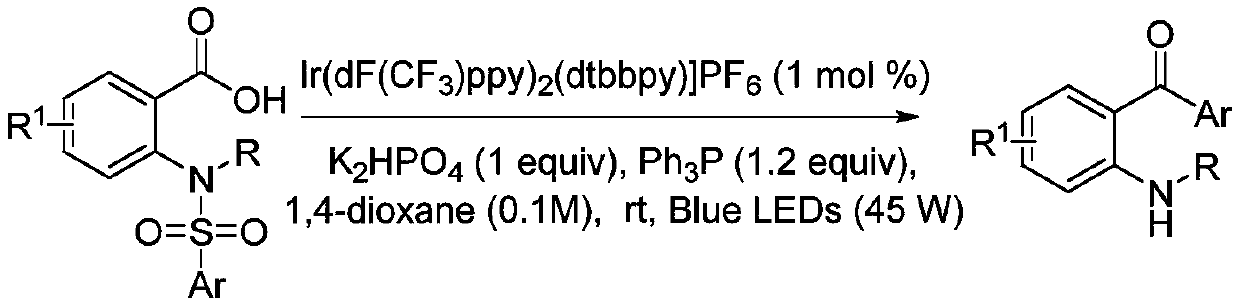

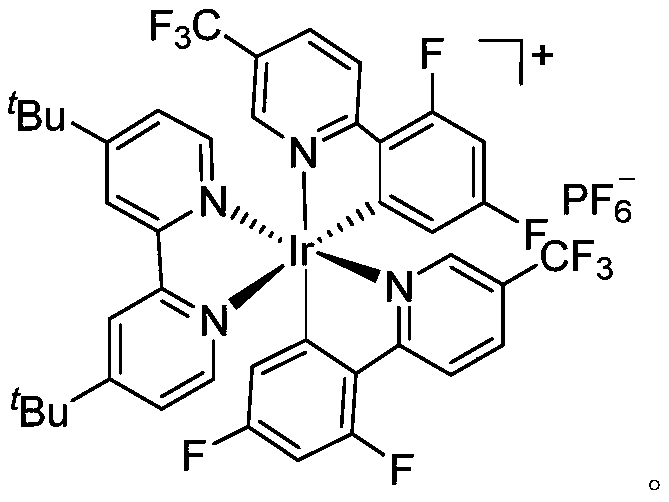

[0024] Weigh first (55.4mg, 0.2mmol), photocatalyst Ir[dF(CF 3 )ppy] 2 (dtbbpy)PF 6 (2.3mg, 1mol%), K 2 HPO 4 (34.8mg, 0.2mmol, 1.0equiv.), triphenylphosphine (62.9mg, 0.24mmol, 1.2equiv.), added to the reaction tube, pumped through the vacuum line for three times, under argon atmosphere, added 2mL1,4 -Dioxane, and then placed under the irradiation of two 45W blue light lamps, and reacted at room temperature for 8 hours. Dry loading, column chromatography (300-400 mesh chromatography silica gel) to obtain the product 29.0mg, (eluent: petroleum ether-ethyl acetate, 5:1, the same below), yield 74%, 1 H NMR (400MHz, CDCl 3 )δ7.65 -7.62(m, 2H), 7.52(t, J=7.3Hz, 1H), 7.45(dd, J=7.9, 6.4Hz, 3H), 7.31-7.27(m, 1H), 6.74(d ,J=8.3Hz,1H),6.60(t,J=7.6Hz,1H),6.11(s,2H). 13 C NMR (100 MHz, CDCl 3 )δ 199.1, 150.9, 140.1, 134.6, 134.3, 131.1, 129.1, 128.1, 118.2, 117.0, 115.5.

Embodiment 2

[0026] Weigh first (58.2mg, 0.2mmol), photocatalyst Ir[dF(CF 3 )ppy] 2 (dtbbpy)PF 6 (2.3mg, 1mol%), K 2 HPO 4 (34.8mg, 0.2mmol, 1.0equiv.), triphenylphosphine (62.9mg, 0.24mmol, 1.2equiv.), added to the reaction tube, pumped through the vacuum line for three times, under argon atmosphere, added 2mL 1, 4-dioxane, and then placed under the irradiation of two 45W blue light lamps, and reacted at room temperature for 8 hours. Dry loading, column chromatography (300-400 mesh chromatography silica gel) to obtain the product 33.4 mg, 69% yield, 1 H NMR (400MHz, CDCl 3 )δ7.56(d, J=8.0Hz, 2H), 7.46(d, J=8.0Hz, 1H), 7.32-7.25(m, 1H), 6.73(d, J=8.3Hz, 1H), 6.60( t,J=7.6Hz,1H),6.00(s,2H),2.43(s,3H). 13 C NMR (100MHz, CDCl 3 )δ198.9, 150.7, 141.7, 137.2, 134.4, 134.0, 129.5, 128.8, 118.5, 117.0, 115.5, 21.6.

Embodiment 3

[0028] Weigh first (61.4mg, 0.2mmol), photocatalyst Ir[dF(CF 3 )ppy] 2 (dtbbpy)PF 6 (2.3mg, 1mol%), K 2 HPO 4 (34.8mg, 0.2mmol, 1.0equiv.), triphenylphosphine (62.9mg, 0.24mmol, 1.2equiv.), added to the reaction tube, pumped through the vacuum line for three times, under argon atmosphere, added 2mL1,4 -Dioxane, and then placed under the irradiation of two 45W blue light lamps, and reacted at room temperature for 8 hours. Dry loading, column chromatography (300-400 mesh chromatography silica gel) to obtain the product 33.4mg, yield 74%, 1 H NMR (400MHz, CDCl 3)δ7.68(d, J=8.8Hz, 2H), 7.46(d, J=9.5Hz, 1H), 7.29(d, J=8.5Hz, 1H), 6.95(d, J=8.8Hz, 2H) ,6.73(d,J=9.1Hz,1H),6.62(t,J=8.1Hz,1H),5.85(s,2H),3.88(s,3H). 13 C NMR (100MHz, CDCl 3 )δ197.8, 162.3, 150.4, 134.0, 133.7, 132.3, 131.8, 119.0, 117.0, 115.6, 113.4, 55.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com