A kind of preparation method and application of bis(n-(4-carboxy)phenyl)peryleneimide zinc complex catalyst

A technology of zinc peryleneimide and peryleneimide, which is applied in the field of preparation of bisphenyl) peryleneimide zinc complex catalysts, can solve the problems of large catalyst consumption and high reaction pressure, and achieve a simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

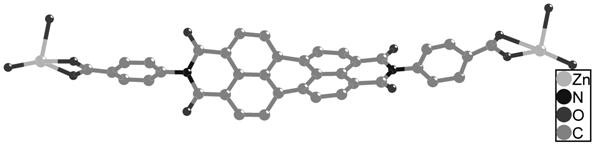

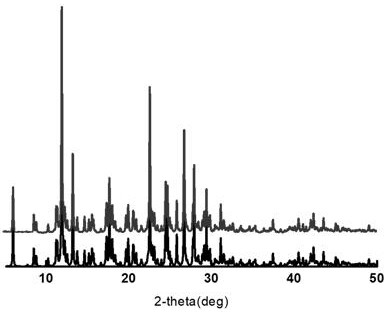

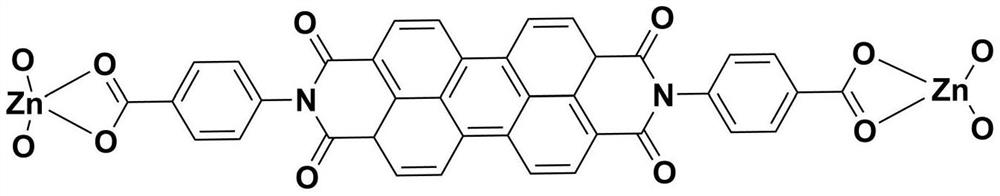

[0028] Embodiment 1: Compound Zn(C 38 h 18 N 2 o 8 ) preparation

[0029] Add bis(N-(4-carboxy)phenyl)peryleneimide (3mmol), triethylamine (5mmol), Zn(OAc) successively in a clean hydrothermal reaction kettle 2 (2mmol), water (8mL) and N,N'-dimethylimide (2mL), stirred vigorously for 2h, then put it into a stainless steel reaction kettle, raised the temperature to 90°C, reacted for 72h, cooled to room temperature after the reaction, A dark red substance was obtained. Yield about 34%.

Embodiment 2

[0030] Embodiment 2: Compound Zn(C 38 h 18 N 2 o 8 ) preparation

[0031] Add bis(N-(4-carboxy)phenyl)peryleneimide (4mmol), triethylamine (8mmol), Zn(OAc) successively in a clean hydrothermal reaction kettle 2 (4mmol), water (10mL) and N,N'-dimethylimide (5mL), stirred vigorously for 3h, then put it into a stainless steel reaction kettle, raised the temperature to 100°C, reacted for 96h, cooled to room temperature after the reaction, A dark red substance was obtained. Yield about 43%.

Embodiment 3

[0032] Embodiment 3: Compound Zn(C 38 h 18 N 2 o 8 ) preparation

[0033] Add bis(N-(4-carboxy)phenyl)peryleneimide (6mmol), triethylamine (13mmol), Zn(OAc) successively in a clean hydrothermal reaction kettle 2 (7mmol), water (15mL) and N,N'-dimethylimide (5mL), stirred vigorously for 5h, then put it into a stainless steel reaction kettle, raised the temperature to 120°C, reacted for 80h, cooled to room temperature after the reaction, A dark red substance was obtained. Yield about 56%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com