Low-melting-point nickel-tungsten intermediate alloy and preparation process thereof

A master alloy and preparation technology, which is applied in the field of low melting point nickel-tungsten master alloy and its preparation, can solve the problems of high energy consumption, high melting point, difficulty in adding tungsten elements, etc., and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

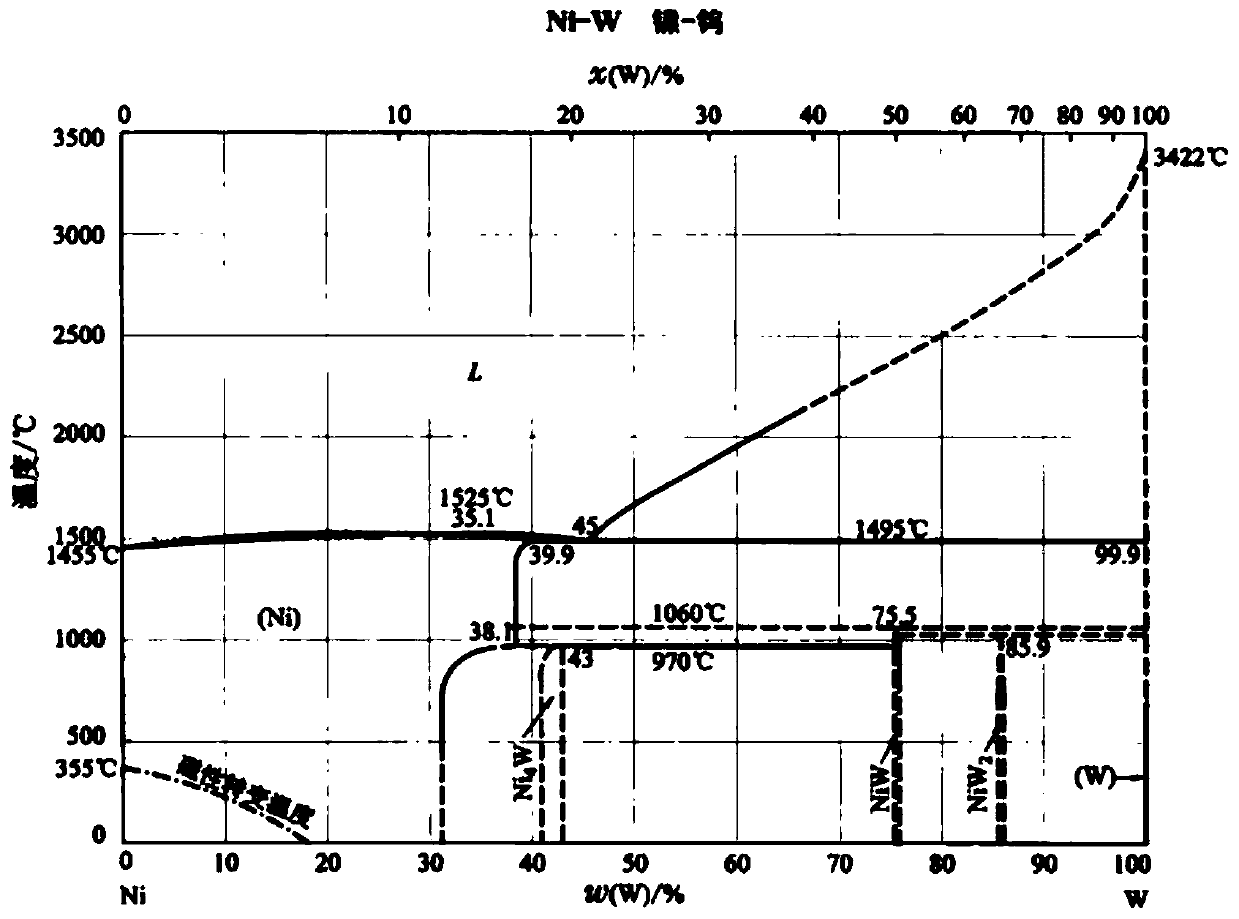

Image

Examples

preparation example Construction

[0032] A preparation process for a low-melting-point nickel-tungsten master alloy, comprising the following steps:

[0033] S1. Raw material preparation:

[0034] Select raw materials according to the following proportions, tungsten powder 38-55%, nickel powder balance,

[0035] Among them, the purity of tungsten powder is ≥99.95%, the particle size is ≥100 mesh, the nickel powder Ni is ≥99.70%, the particle size is ≥100 mesh;

[0036] S2, mixing materials:

[0037] Mix the selected tungsten powder and nickel powder into the mixer for mixing, and the mixing time is ≥4h; the mass ratio of tungsten powder and nickel powder is proportioned according to different grades or user requirements;

[0038] S3, molding:

[0039] The mixed powder is molded on an isostatic press or a hydraulic press to make a round billet or a square billet; the molding pressure is ≥200Mpa / cm 2 ;

[0040] S4. High temperature sintering:

[0041] Carrying out high-temperature sintering of round billet...

Embodiment 1

[0045] A nickel-tungsten master alloy with a low melting point is prepared from the following raw material ratios: 45% tungsten powder and 55% nickel powder; the tungsten powder has a purity of 99.96% and a particle size of 120 mesh; the nickel powder has a purity of 99.80% and a particle size of 150 mesh. The preparation process of nickel-tungsten master alloy in this embodiment, S1, raw material preparation: select raw materials according to the following ratio, tungsten powder 45%, nickel powder 55%; the purity of the tungsten powder is 99.96%, the particle size is 120 mesh; the nickel powder The purity of the powder is 99.80%, and the particle size is 150 mesh; S2, mixing: mix the selected tungsten powder and nickel powder into the mixing machine for mixing, and the mixing time is 5 hours; S3, molding: mix the mixed powder Formed on an isostatic press or hydraulic press to make round or square blanks; the forming pressure is 500Mpa / cm 2 ; S4, high-temperature sintering: ca...

Embodiment 2

[0048] A nickel-tungsten master alloy with a low melting point, which is made of the following raw material ratios: 48% tungsten powder and 52% nickel powder; the tungsten powder has a purity of 99.97% and a particle size of 150 mesh; the nickel powder has a purity of 99.90% and a particle size of 180 mesh. The preparation process of nickel-tungsten master alloy in this embodiment, S1, raw material preparation: select raw materials according to the following ratio, tungsten powder 48%, nickel powder 52%; the purity of the tungsten powder is 99.97%, the particle size is 150 mesh; the nickel powder The powder purity is 99.90%, and the particle size is 180 mesh; S2, mixing: mix the selected tungsten powder and nickel powder into the mixing machine for mixing, and the mixing time is 8 hours; S3, forming: mix the mixed powder Formed on an isostatic press or hydraulic press to make round or square blanks; the forming pressure is 400Mpa / cm 2 ; S4, high-temperature sintering: carry ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com