Low-wind-speed wind generating set variable speed turning system and method

A technology for wind turbines and low wind speed, which is applied to wind turbines, assembly of wind turbines, and wind power generation. It can solve problems such as small ground space, difficulty in hoisting large impellers, and difficulty in requisitioning machine positions, achieving improved safety, The effect of overcoming large resistance and various uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

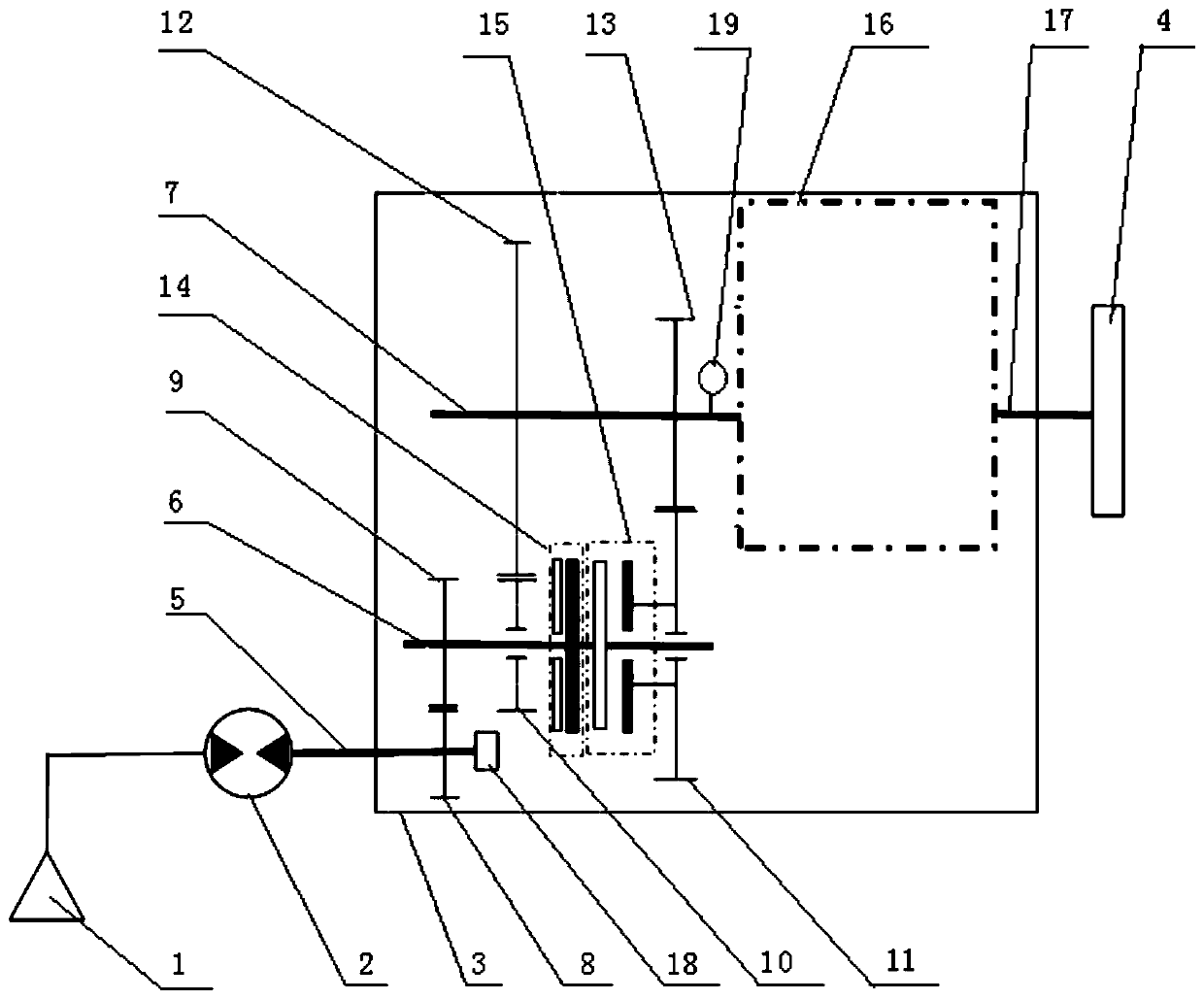

[0032] Refer to attached figure 1 As shown, the variable speed barring system of the low wind speed wind power generating set in this embodiment includes a control mechanism 1 , a motor 2 and a hydraulic gearbox 3 connected thereto.

[0033]In this embodiment, the control mechanism 1 includes a hydraulic power mechanism and a control terminal. The hydraulic power mechanism includes a fuel tank, an oil pump, a cooling motor, an electric control element, a hydraulic element, and related sensors. The hydraulic transmission powers the hydraulic power unit. The control terminal is connected to the power end of the wind turbine cabin cabinet through a cable to meet the power-on requirements for the cranking system. The control terminal also includes various control buttons for controlling the cranking system to perform fast and slow cranking actions. .

[0034] The motor 2 is connected to the oil pump through a hydraulic pipeline, and the hydraulic pipeline is provided with a runn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com