Method and device for detecting deviation degree of camera image plane in vertical optical axis direction

A technology of optical axis direction and detection method, which is applied in measurement devices, optical devices, optical performance testing, etc., can solve the problems of imaging quality deviation and complex detection methods, and achieves improved manufacturing quality, improved imaging quality and consistency, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

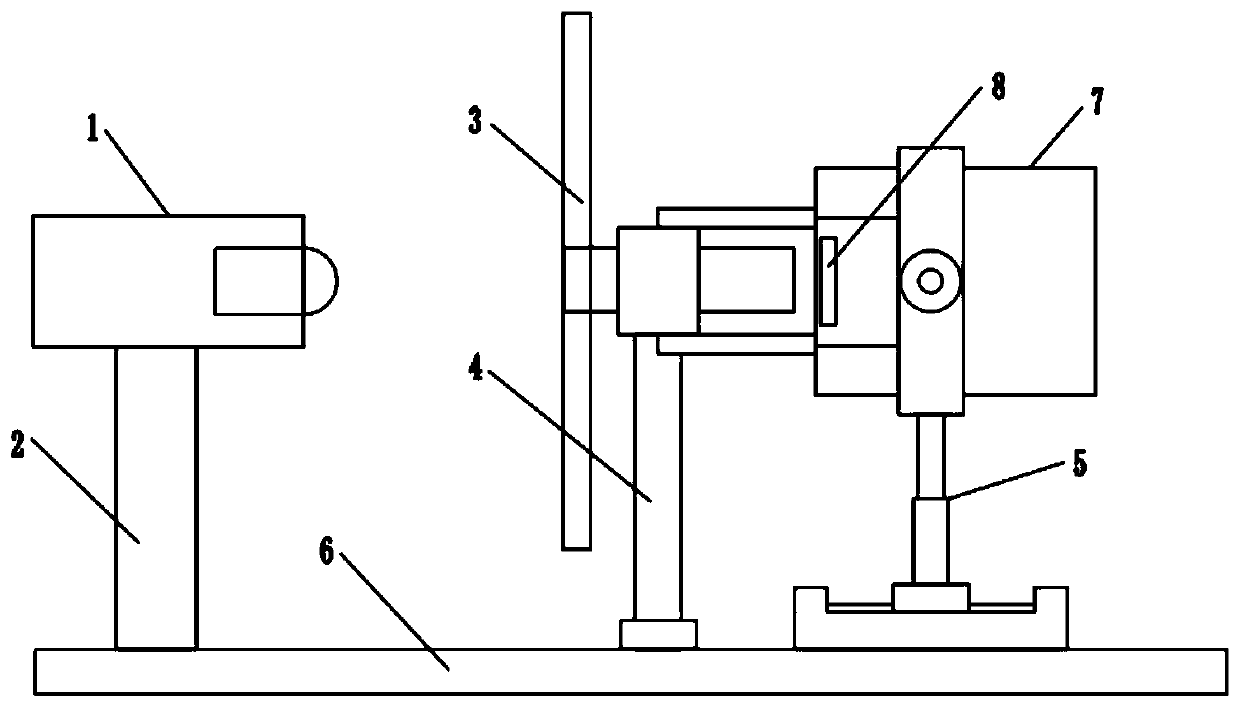

[0026] as attached Figure 1~5 The method for detecting the deviation degree of the vertical optical axis of the camera image plane includes steps A, coaxial adjustment, B, light source irradiation, C, light and shadow acquisition and capture, D, deviation degree calculation, and the specific steps are as follows:

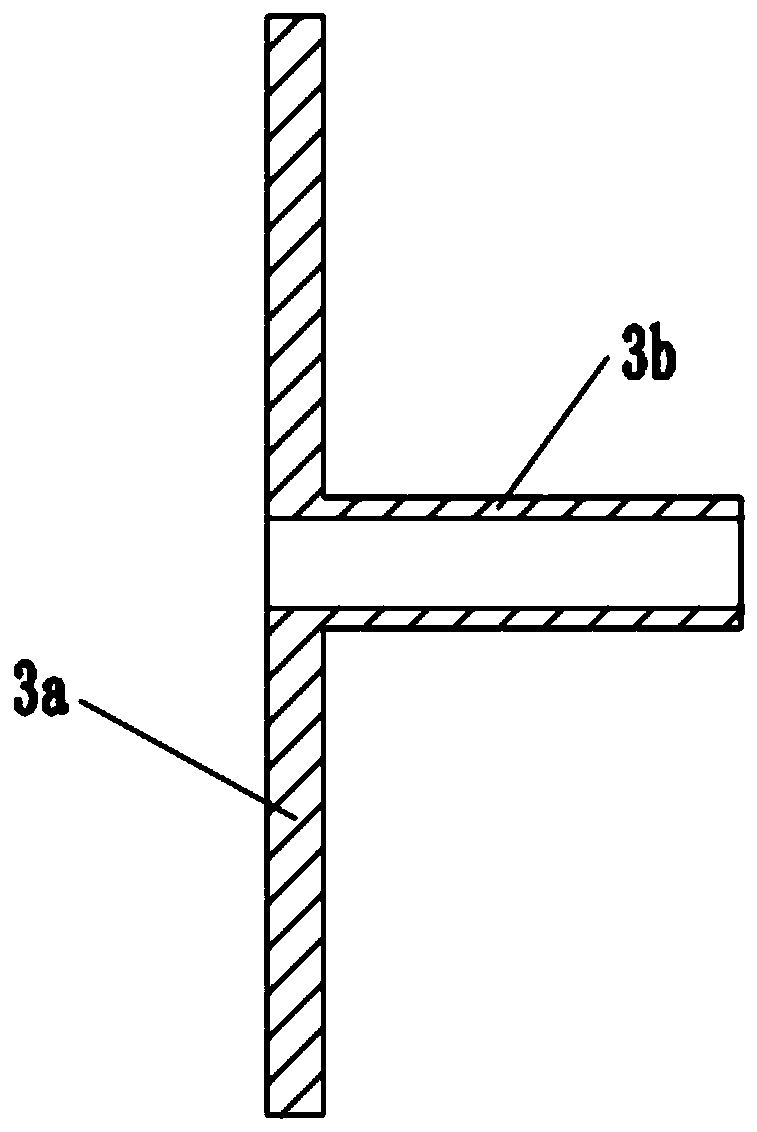

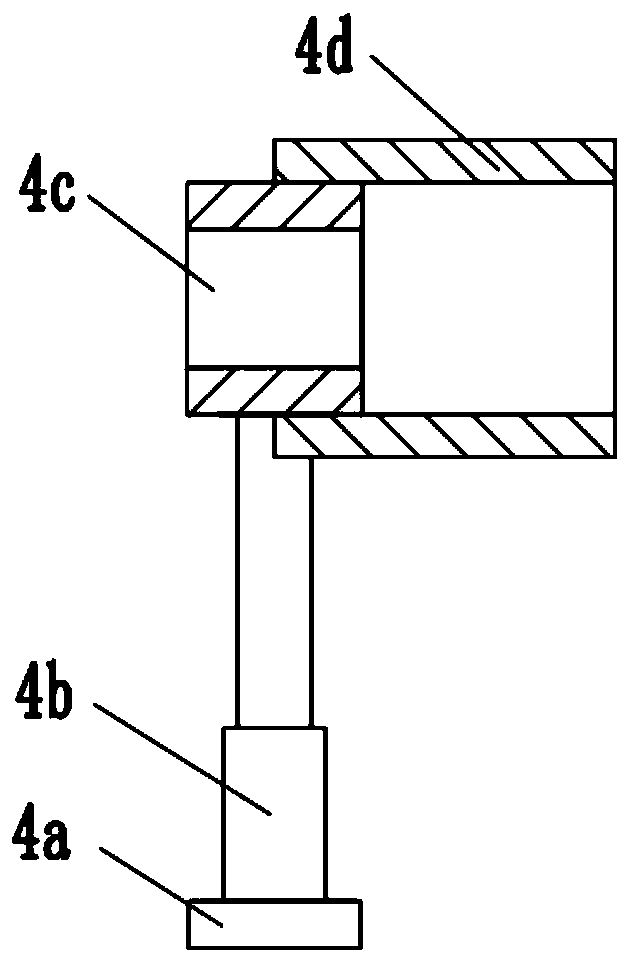

[0027] A. Coaxial debugging, place the camera under test 7 on the detection fixture 5, make the camera under test 7 make the camera image sensor 8 match the detection tube 3b of the detector 3 on the frame 6, and adjust the camera image sensor 8 to approach the detection The detection tube 3b of device 3;

[0028] B, light source 1 irradiation, open the light source 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com