A method for detecting scale peeling performance of hot-rolled wire rod

A technology of hot-rolled wire rod and detection method, which is applied to measurement devices, material weighing, instruments, etc., can solve the problems of cumbersome inspection steps, high risk of human error, poor mechanical peeling effect, etc., and achieves simple and accurate inspection steps. Evaluate the effect of accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

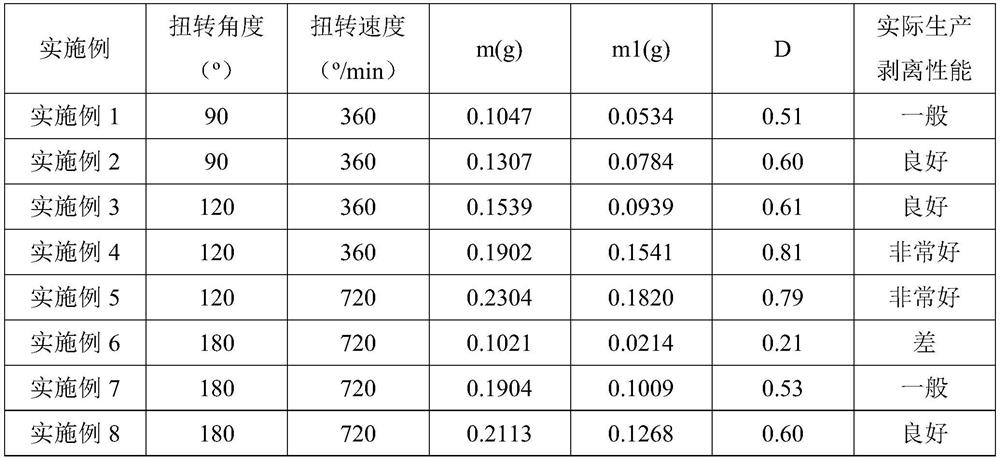

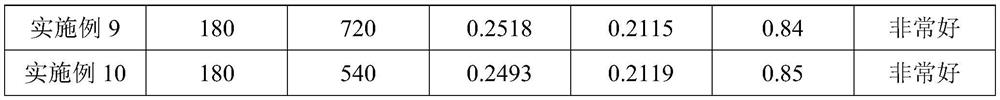

Embodiment 1

[0025] Take a Φ5.5mm SWRH72A hot-rolled wire rod with a length of 290mm, straighten the wire rod with a wooden hammer or a straightening machine, align the clamps of the wire torsion testing machine, clamp the two ends of the sample on the wire torsion testing machine, and twist The speed is 360° / min, and one side is twisted 90°, so that the scale falls off during the twisting process of the sample, and the peeled scale is collected and weighed. The large-scale scale, m1 is 0.0534g, and the calculated stripping performance index D is 0.51.

Embodiment 2

[0027] Take a Φ5.5mm LX72A hot-rolled wire rod with a length of 290mm. After straightening the wire rod with a wooden hammer or a leveler, align the clamps of the wire torsion testing machine, and clamp the two ends of the sample on the wire torsion testing machine. The torsion speed is 360° / min, and the one-side twist is 90°, so that the scale falls off during the twisting process of the sample, and the peeled scale is collected and weighed. The m is 0.1307g, and the scale is screened with a 6-mesh sieve and weighed The m1 of the screened large scale scale is 0.0784g, and the calculated stripping performance index D is 0.60.

Embodiment 3

[0029] Take a Φ5.5mm LX72A hot-rolled wire rod with a length of 290mm. After straightening the wire rod with a wooden hammer or a leveler, align the clamps of the wire torsion testing machine, and clamp the two ends of the sample on the wire torsion testing machine. The torsion speed is 360° / min, and the one-side twist is 120°, so that the scale falls off during the twisting process of the sample, and the peeled scale is collected and weighed. The m is 0.1539g, and the scale is screened with a 6-mesh sieve. The large-sized oxide scale, m1 is 0.0939g, and the calculated stripping performance index D is 0.61.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com