Thin film transistor and manufacturing method thereof

A technology for thin film transistors and fabrication methods, which are applied in transistors, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as high cost and complex process, reduce electric field intensity, simplify process process, and suppress hot carrier effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present disclosure may be practiced. In the figures, structurally similar elements are denoted by the same reference numerals.

[0026] The implementation process of the embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings.

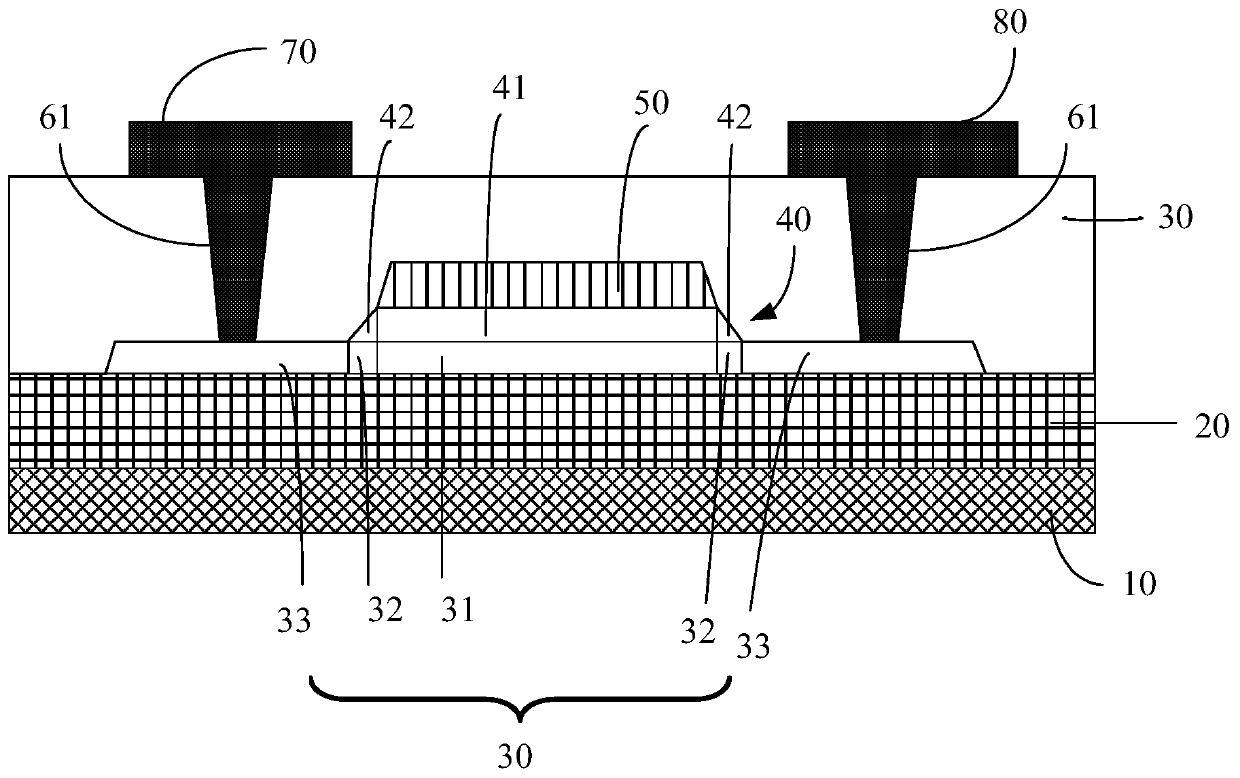

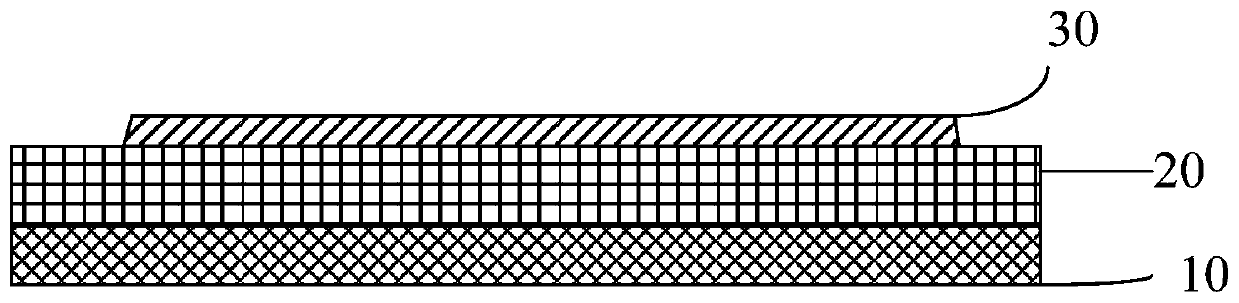

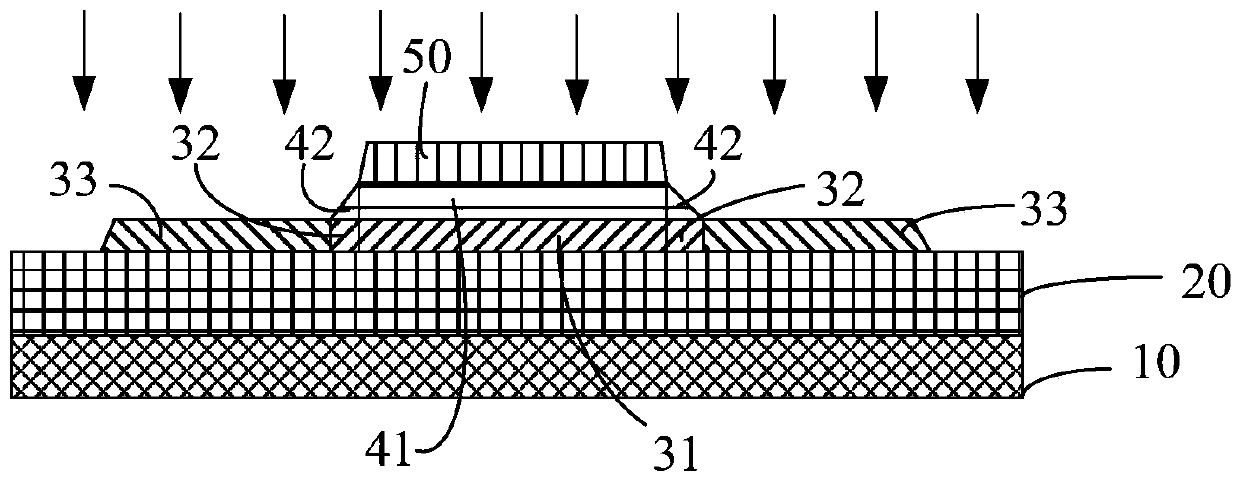

[0027] see Figure 1 to Figure 2A -2C, figure 1 It is a schematic diagram of the structure of the disclosed thin film transistor. Figures 2A-2C It is a schematic flow chart of the manufacturing method of the thin film transistor disclosed herein. The disclosure provides a thin film transistor, comprising: a substrate 10; a buffer layer 20 disposed on the substrate 10; a polysilicon layer 30 disposed on the buffer layer 20, the polysilicon layer 30 comprising a channel region 31, two lightly doped regions 32 arranged on both sides of the channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com