Epoxy resin-based composite insulating material and preparation method thereof

An epoxy resin, composite insulation technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problem of low breakdown field strength of composite insulation materials, and achieve stable DC breakdown field strength and good breakdown strength. , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

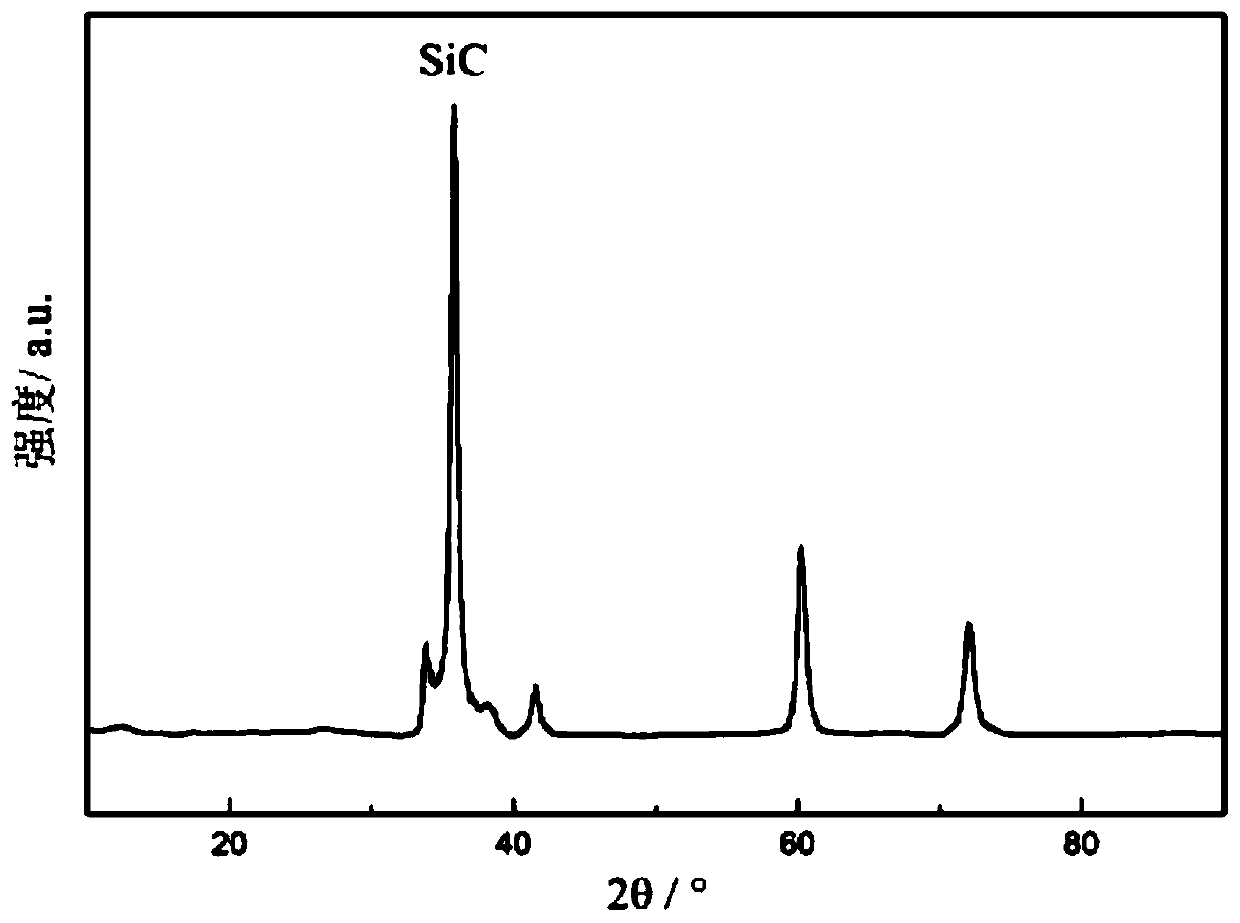

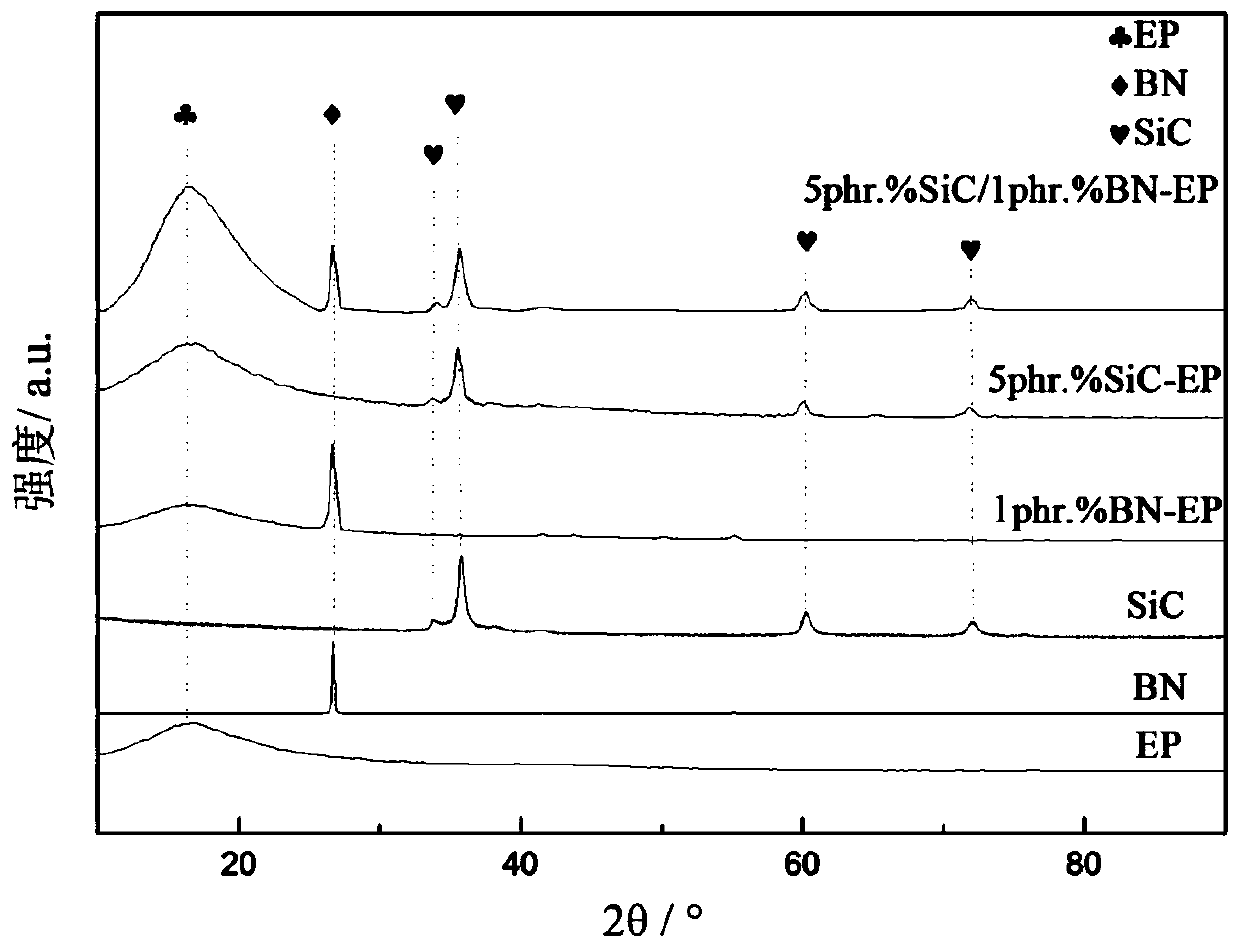

[0031] An epoxy resin-based composite insulating material, comprising the following components in parts by mass: 1.45-4.09 parts of silicon carbide nanoparticles, 0.47 parts of hexagonal boron nitride sheet, 25 parts of epoxy resin, 22 parts of curing agent and 0.03 parts of accelerator .

Embodiment 2

[0033] An epoxy resin-based composite insulating material, comprising the following components in parts by mass: 1.45-4.09 parts of silicon carbide nanoparticles, 0.47 parts of hexagonal boron nitride sheet, 25 parts of epoxy resin, 22 parts of curing agent and 0.03 parts of accelerator .

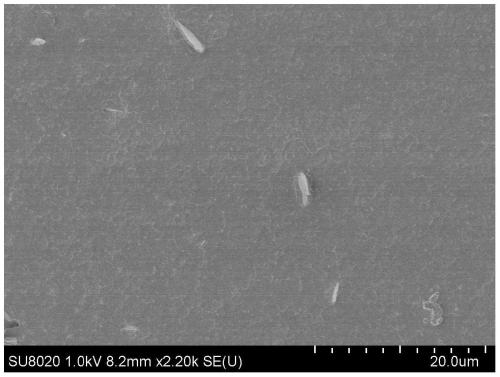

[0034] In this embodiment, the particle size of the silicon carbide nanoparticles is 30-50 nm, the thickness of the hexagonal boron nitride sheet is 80-150 nm, and the diameter is 3-5 μm.

Embodiment 3

[0036] An epoxy resin-based composite insulating material, comprising the following components in parts by mass: 1.45-4.09 parts of silicon carbide nanoparticles, 0.47 parts of hexagonal boron nitride sheet, 25 parts of epoxy resin, 22 parts of curing agent and 0.03 parts of accelerator , wherein the silicon carbide nanoparticles have a particle size of 30-50 nm, the hexagonal boron nitride sheet has a thickness of 80-150 nm, and a diameter of 3-5 μm.

[0037] In this embodiment, the epoxy resin is E-51 type phenolic propane polyester resin, E-44 type epoxy resin, bisphenol A type epoxy resin, polyphenol type glycidyl ether epoxy resin or glycidyl ester type One of the epoxy resins; the curing agent is methyl hexahydrophthalic anhydride, and the accelerator is 2-ethyl-4-methylimidazole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com