Method of dyeing high-flame-retardant tooling fabric

A dyeing method and high flame retardant technology, applied in the field of fabrics in the textile industry, can solve problems such as restricting the application and promotion of fibers, and achieve the effects of preventing whitening, facilitating adsorption, and overcoming poor hygroscopicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

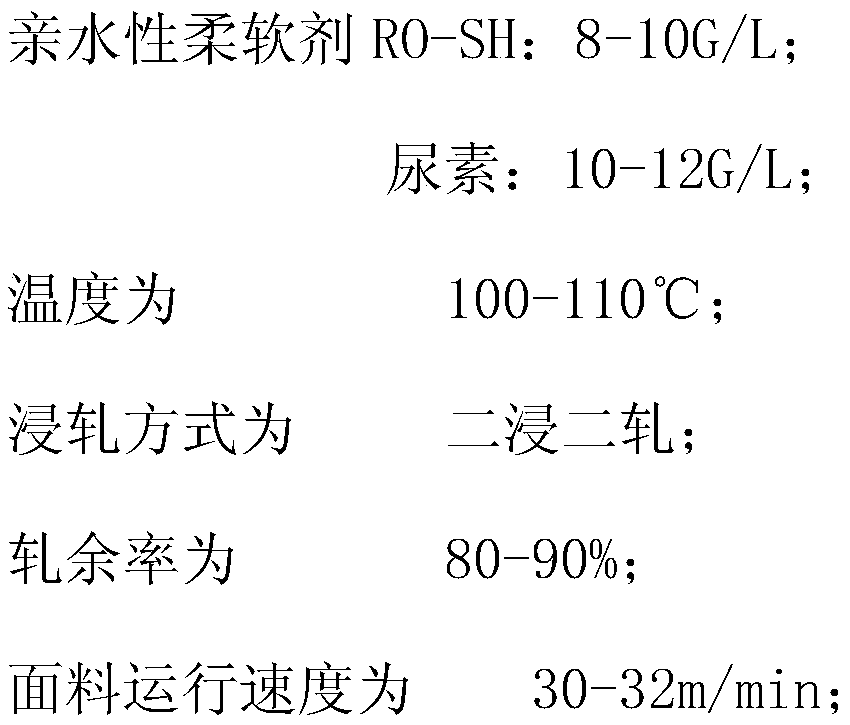

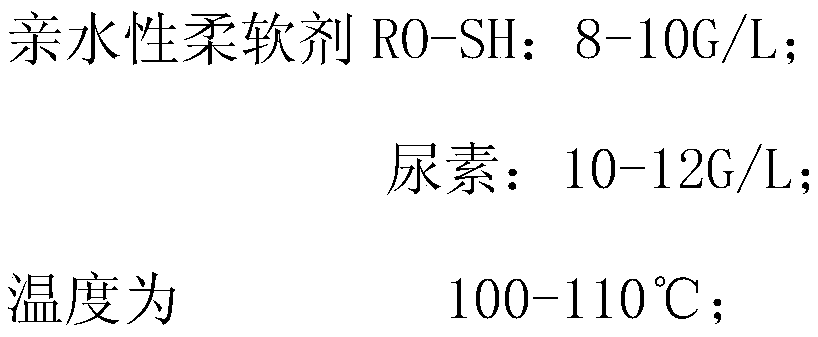

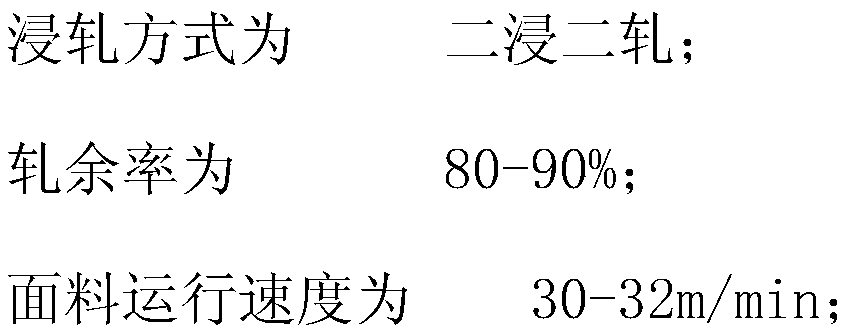

[0026] The present invention adopts warp yarn 14.5tex * weft yarn 14.5tex, 100% polyimide yarn, warp density 120 per inch * weft density 90 per inch, width 152-154 centimeters, plain weave tooling fabric, the fabric is soaked Roll the pre-treatment liquid with strong hydrophilicity and hygroscopicity, and then carry out digital printing of nano-coating ink on the front and back sides, drying, baking and setting, and produce high flame-retardant, multi-color tooling fabrics, ignition 6 It can't burn in minutes, and the flame-retardant effect reaches the level of incombustibility. It is suitable for the functional requirements of clothing in special protective industries such as firefighting, steelmaking, and forest firefighting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com