Production method of ultra-warmth digital printing knitted fleece fabric

A digital printing and production method technology, applied in the processing of textile materials, knitting, weft knitting, etc., can solve the problems that restrict the application and promotion of fibers, and achieve the effect of easy adsorption and overcome poor hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

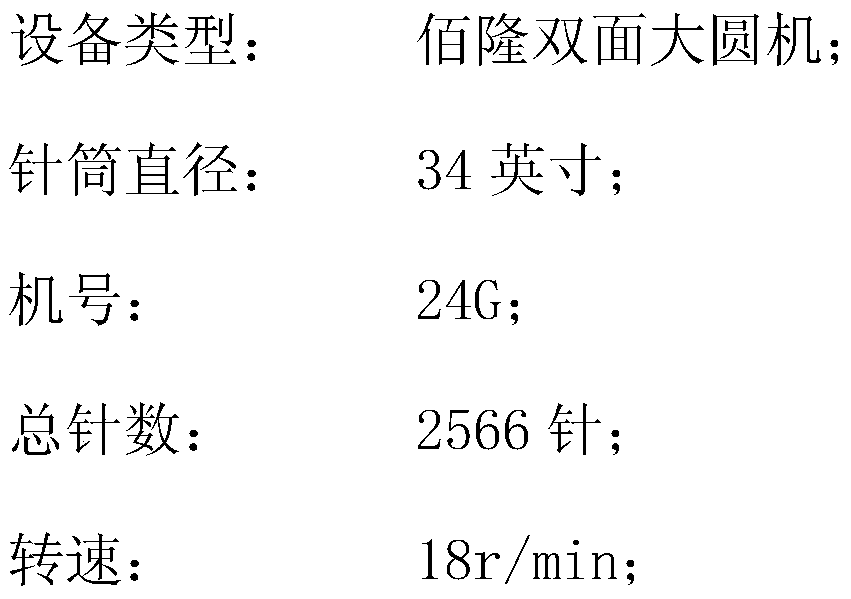

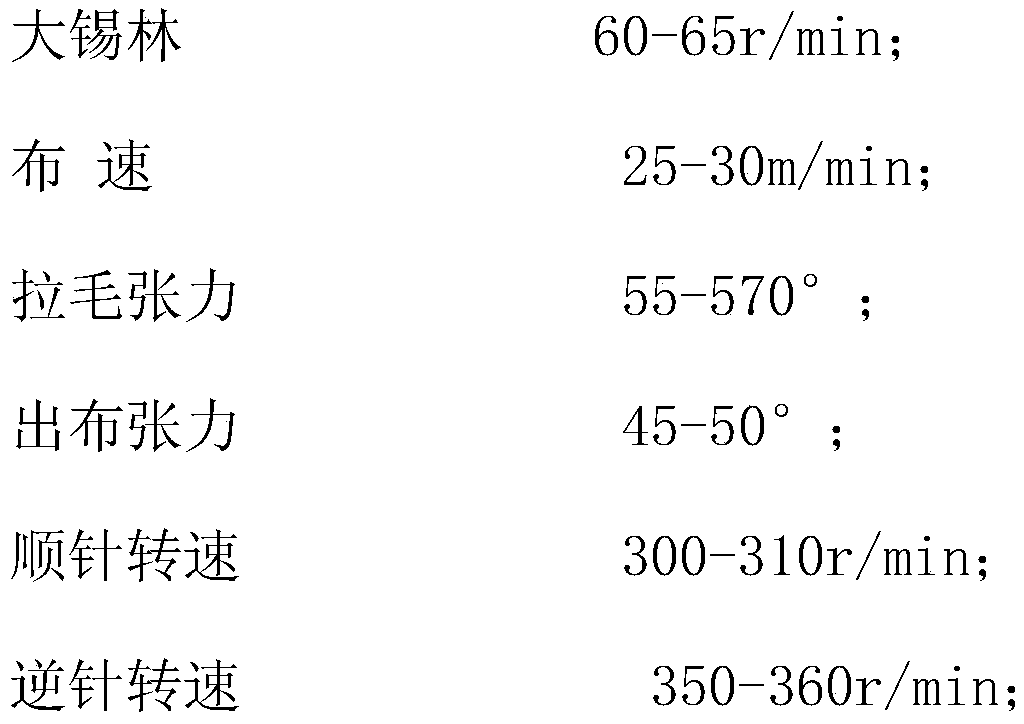

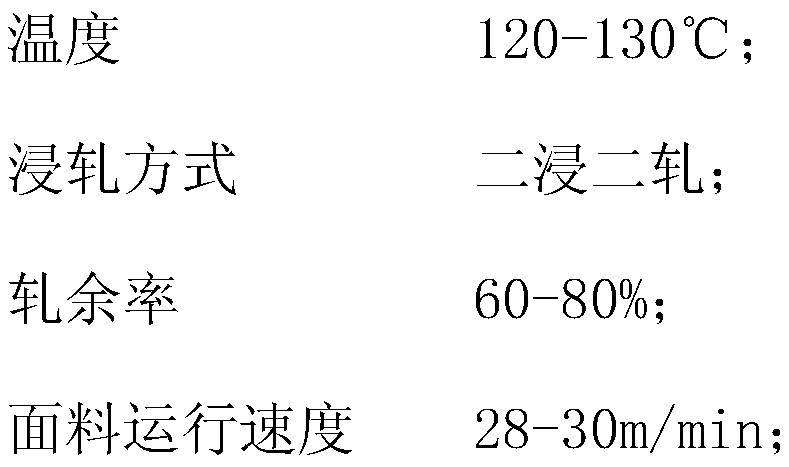

[0031] The present invention adopts 14.5tex, 100% polyimide yarn to weave on a double-sided circular knitting machine, one side is brushed, and the brushed fabric is dipped and rolled twice with a pre-treatment liquid with strong hydrophilicity and hygroscopicity, and at the same time, the pre-treatment liquid is well controlled. The liquid-carrying rate of the treatment liquid adopts nano-scale paint ink for DuPont digital printing to prevent the large pigment particles in ordinary paint from causing poor rubbing fastness. On the non-velvet side of the fabric, white ink is first used as a primer, and then digital printing is carried out, and infrared drying is used to fully cross-link the ink and yarn. After testing, the fabric thermal resistance = 0.17334㎡·k / w, Cro value = 1.11834clo, thermal conductivity = 0.11538w / (m·k), heat transfer coefficient = 5.769w / (㎡·k), which is the existing Among the fibers, it is the fabric with the best heat preservation and heat insulation. It...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com