Mask assembly and exposure method thereof

A component and mask technology, applied in the field of flat panel display, can solve the problem of high cost, achieve the effect of reducing process cost, facilitating cost control, and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

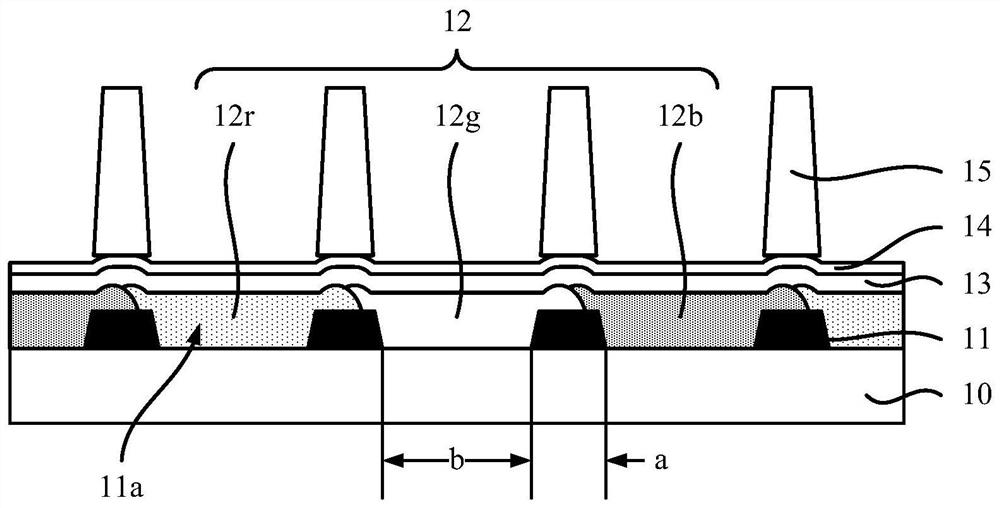

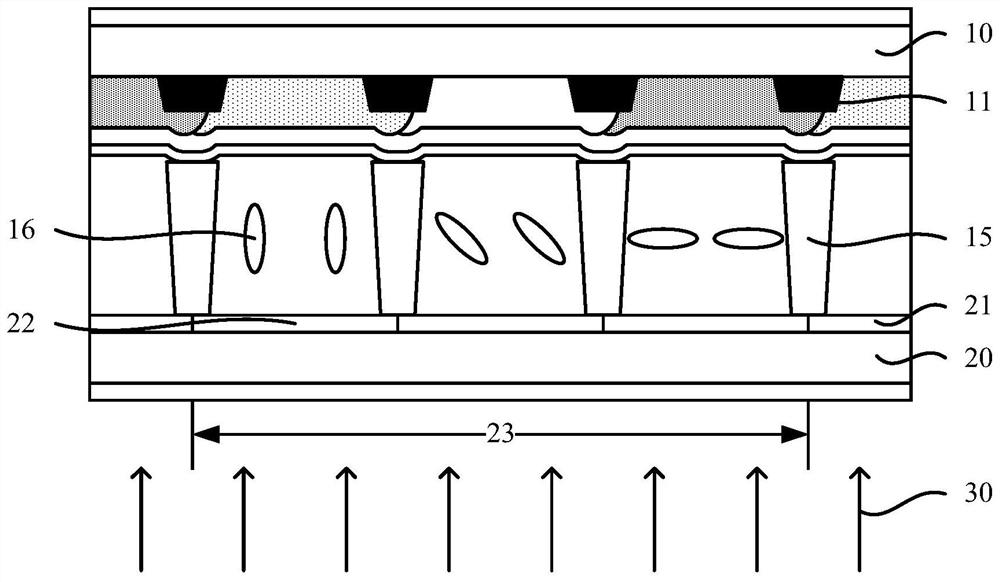

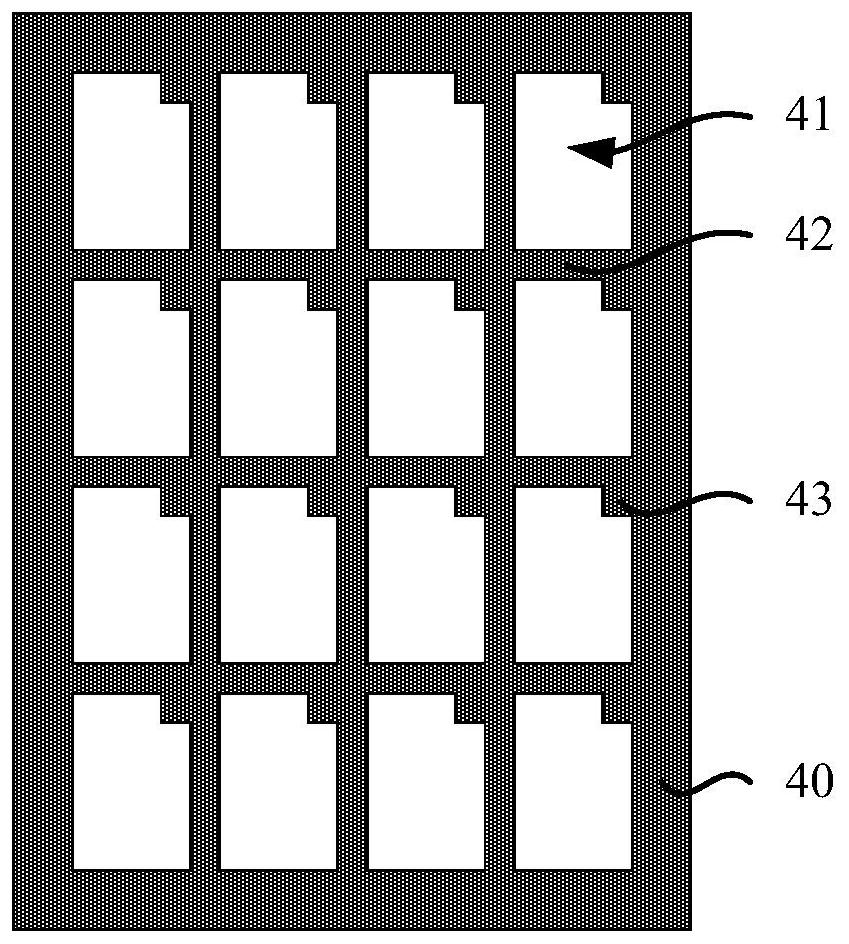

[0056] It can be known from the background art that the cost of forming color filter substrates with different shapes, line widths and line spacings in the prior art is relatively high. Now combined with the structure of a color filter substrate to analyze the reasons for its high cost:

[0057] According to the different requirements of end customers, the shape of each layer on the color filter substrate will be adjusted accordingly: in fast-moving consumer goods such as mobile phones and tablets, the liquid crystal display panel needs to have bright colors (hue, color saturation, brightness), image quality Clear (resolution, PPI), smooth picture (liquid crystal response speed) and other characteristics, but because the environment in which fast-moving consumer goods are generally relatively stable, so fast-moving consumer goods have an impact on product life (reliability, adhesion) and stability (extremely high and low temperature). , high humidity, continuous vibration) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com