An air-cooled heat sink for high-power igbt modules considering operating conditions

It is a technology with high operating conditions and high power. It is applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc. It can solve problems such as inconvenient water and inability to dissipate heat, uneven distribution of IGBT module junction temperature or case temperature, and achieve convenience. Large-area application, improved reliability and service life, and reduced thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Describe the present invention in detail below in conjunction with embodiment and accompanying drawing. The embodiment is based on the specific implementation carried out on the premise of the technical solution of the present invention, and provides detailed implementation methods and processes. However, the protection scope of the claims of the present application is not limited to the description of the following embodiments.

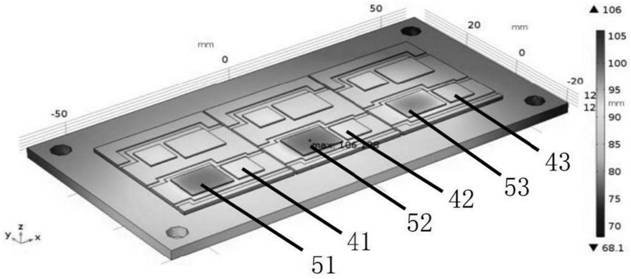

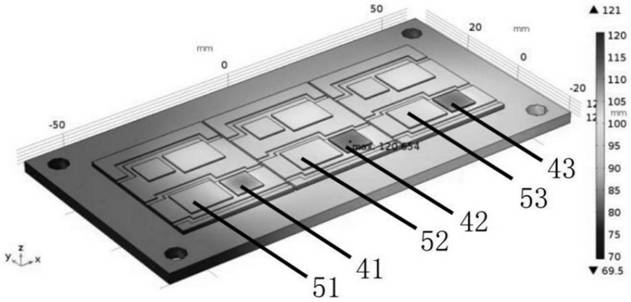

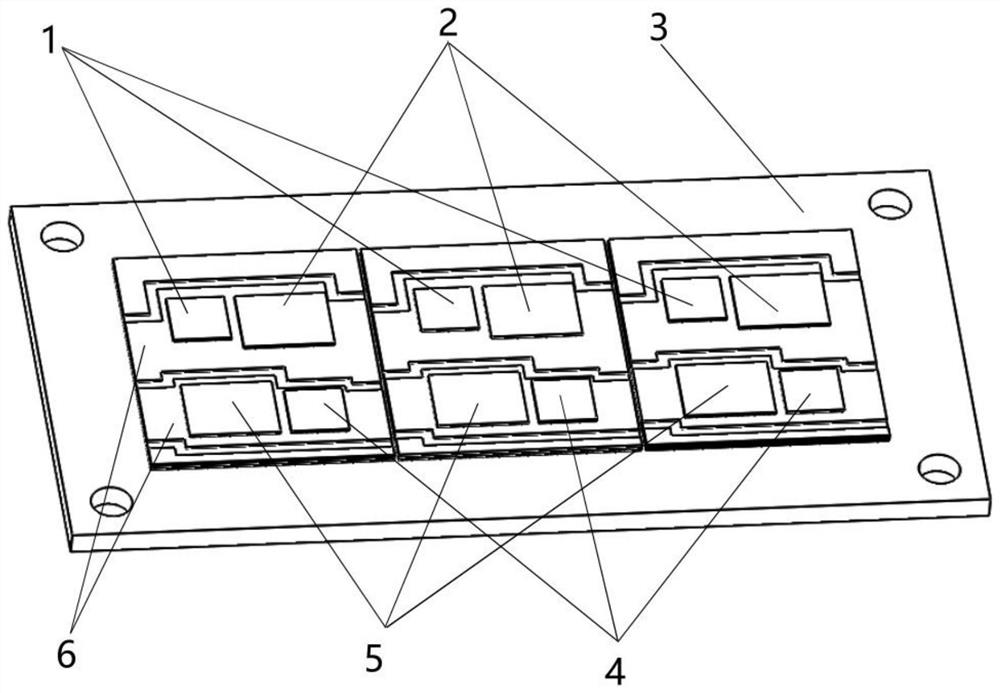

[0021] The invention provides a high-power IGBT module air-cooled heat sink (abbreviated as air-cooled heat sink, see Figure 5-7 ), including a copper cooling base 22 installed on the back of the copper substrate 3 of the IGBT module, a cooling fin 23 vertically welded on the outer surface of the copper cooling base 22, and a cooling fan 27 arranged on one side of the cooling fin 23 A depression 310 is set on the position outside the copper heat dissipation base 22 corresponding to the IGBT chip 5, or a depression 313 is set on the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com