Wheat seeding machine

A seeder and wheat technology, applied in the directions of sowing seeders, seeder parts, planting methods, etc., can solve problems such as the inability to achieve consistent and uniform sowing depths, affect the growth of wheat roots in winter, and reduce operating efficiency, and achieve unique self-cultivation. Adjust balance ability, good passability, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

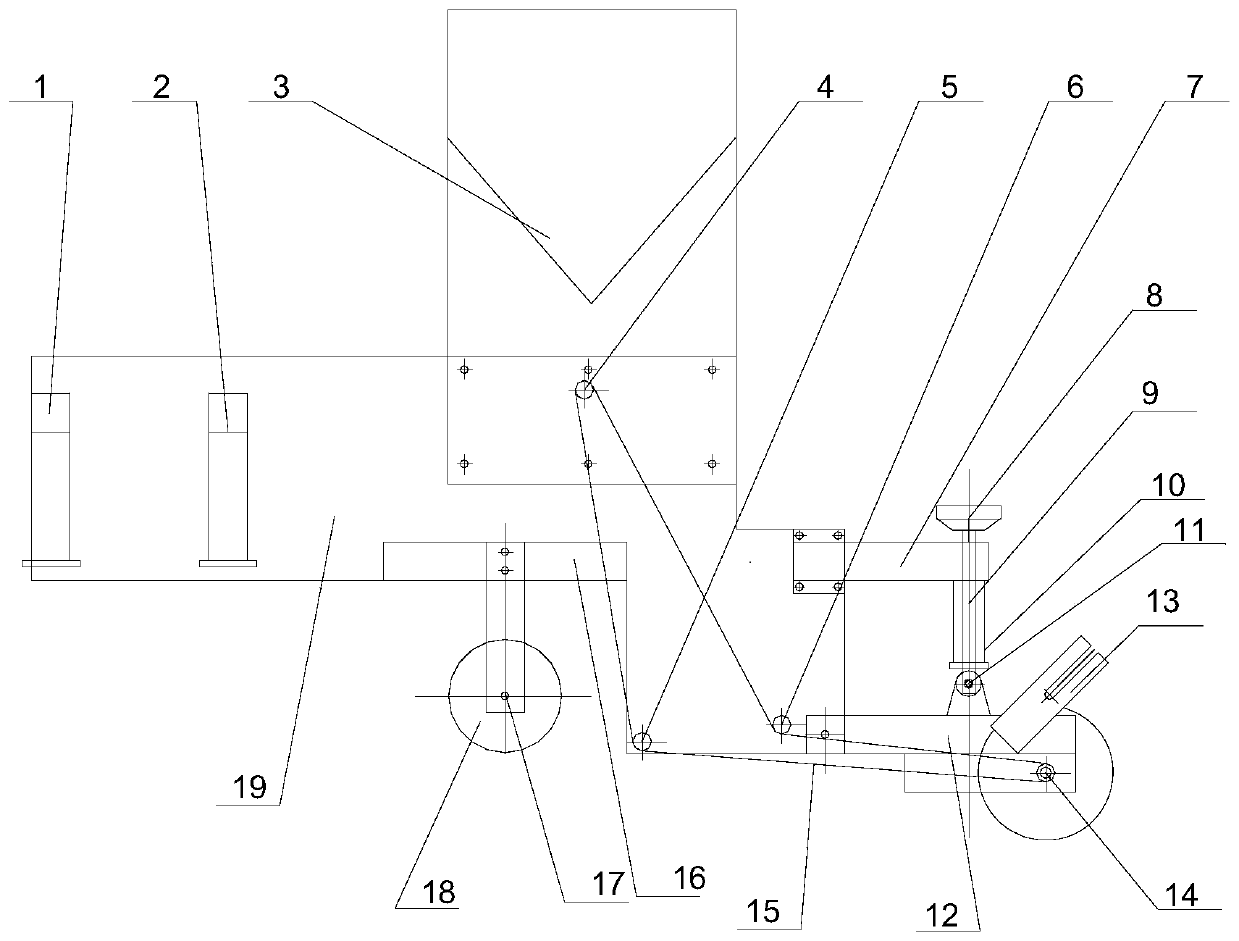

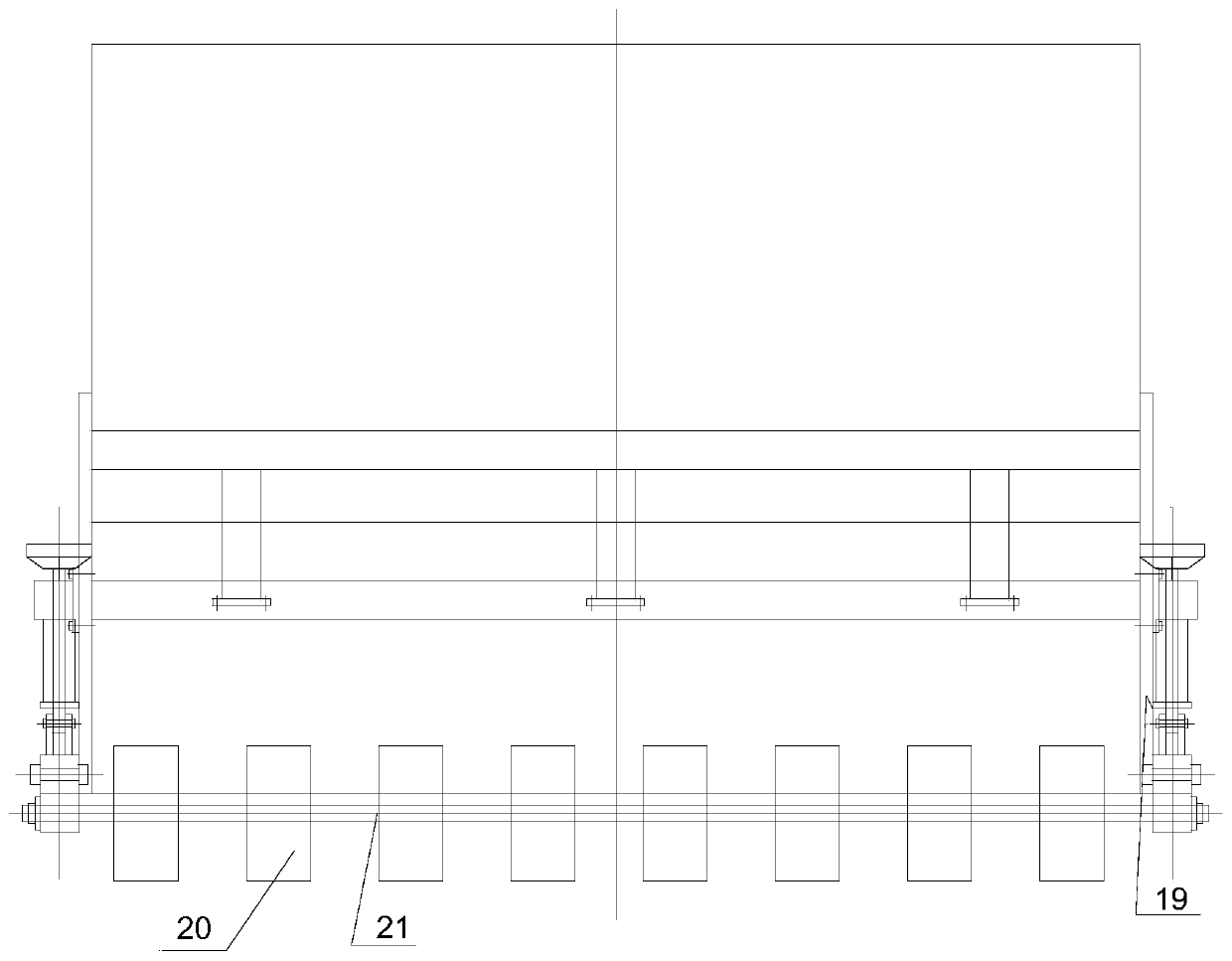

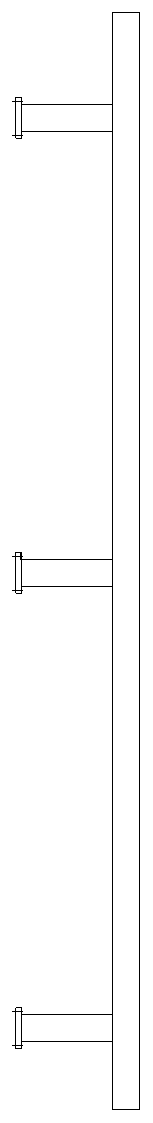

[0025] In order to better illustrate the present invention, the following will be described in detail in conjunction with the accompanying drawings.

[0026] Such as Figure 1-14 As shown, a wheat planter includes a front drive rake and a planter, the front drive rake connecting frame double beams and two side pull plates fasten the planter to the front drive rake, and the front drive rake includes a main frame Fixed frame, floating traction shaft, driving rake, front pressing wheel 20, the floating traction shaft connected with the traction tractor is installed on the front part of the pull plate on both sides of the main frame fixed frame 1, 2, the floating traction shaft floating up and down and the driving The rake is connected, the front pressing wheel and the driving rake body adopt a split structure, and are fixed and connected with a pull plate, and the pull plate is fixed with a U-shaped groove; double profiling pressing wheel shafts are installed at the rear of both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com