Box type integrated cold aluminum ash treating equipment

A processing equipment and integrated technology, applied in grain processing, solid separation, sieving, etc., can solve problems such as large environmental pollution, inability to work continuously, noise, etc., to achieve high integration, convenient movement, and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

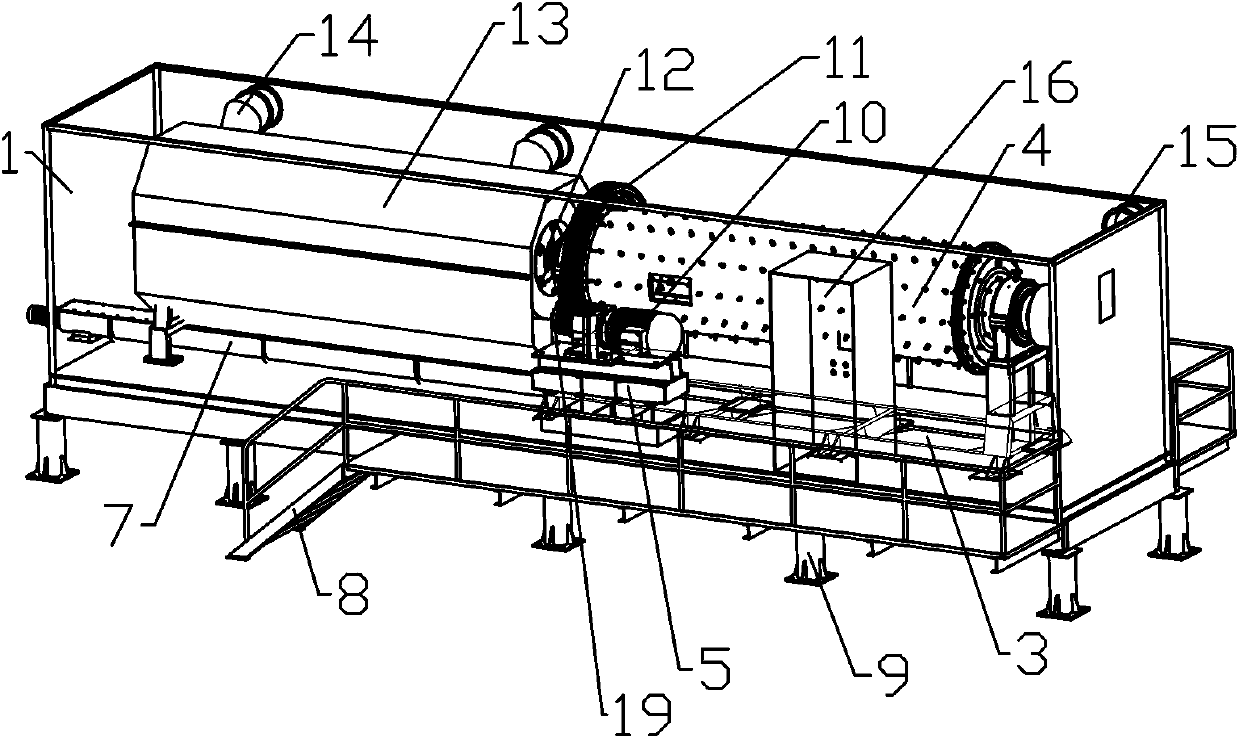

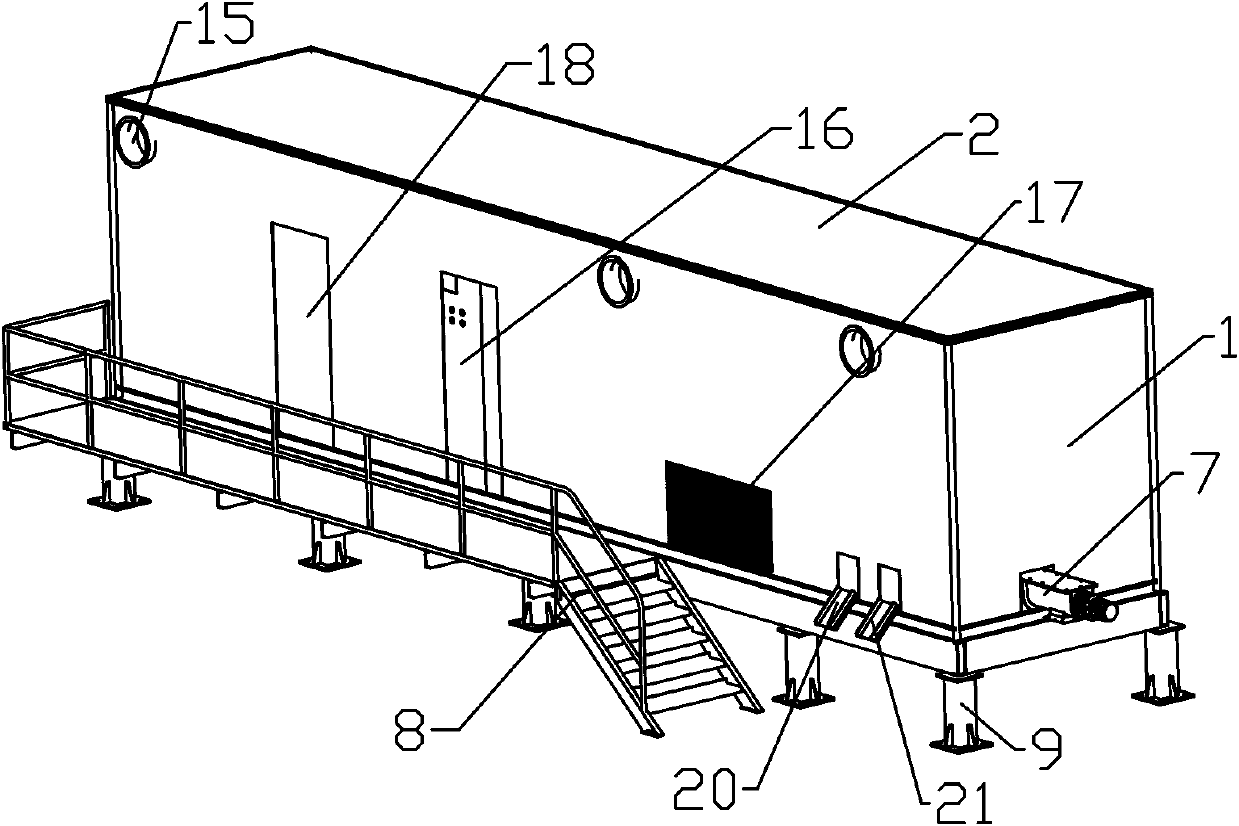

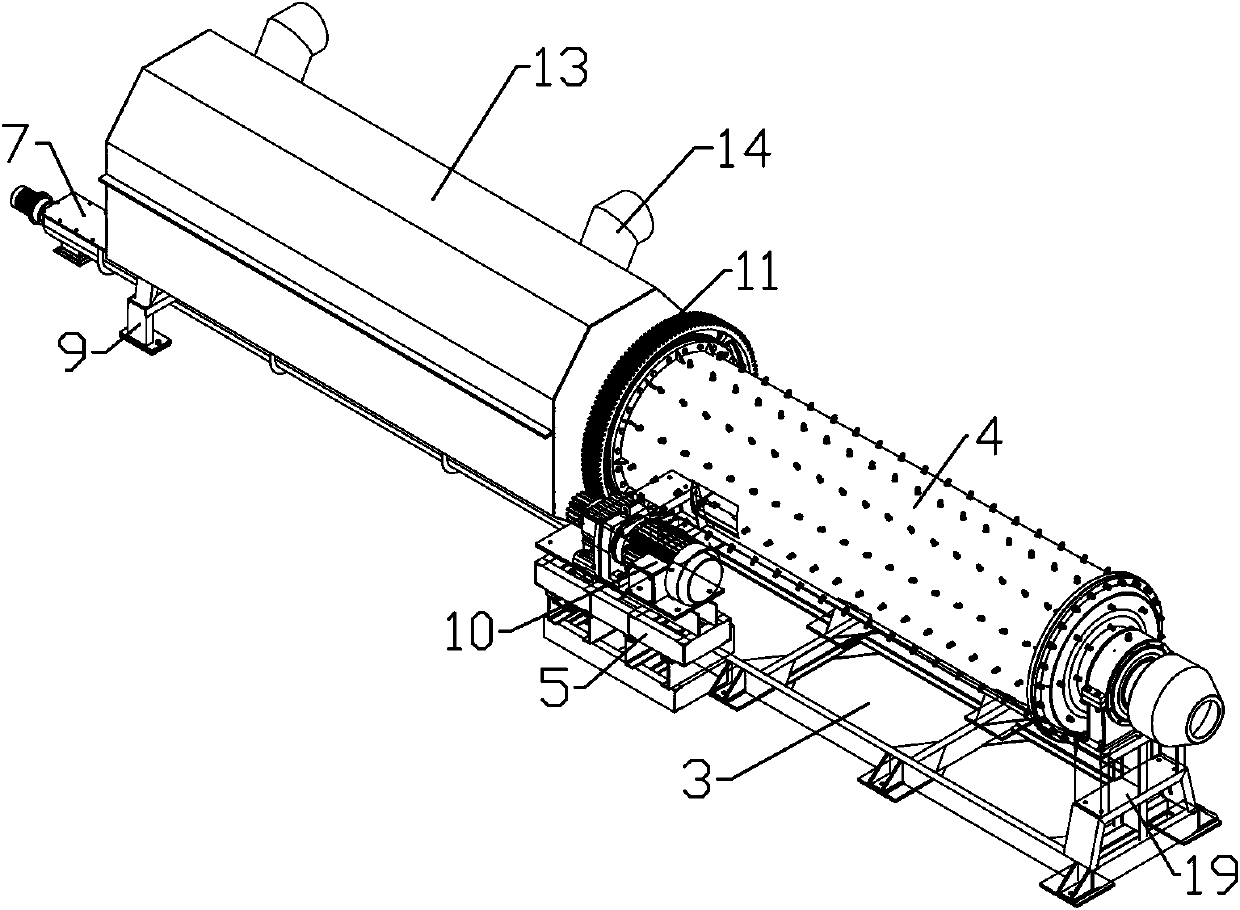

[0025] Such as Figure 1-5 As shown, a box-type integrated cold aluminum ash processing equipment includes a box body 1. For the convenience of manufacture, the box body 1 is a container, and a steel frame is installed on the outer surface of the bottom of the container, and a support leg 9 is installed at the lower end of the frame. The lower end is a fixed plate, and the fixed plate is processed with bolt holes for fixing with the foundation. Triangular reinforcing ribs are welded between the fixed plate and the outrigger 9, and a rubber shock-isolating pad is installed on the lower end of the fixed plate, which can effectively isolate the vibration , a base 3 is installed in the box body 1, the base 3 is a steel structure frame, a ball mill 4 is installed on the base 3, grinding blocks are filled in the ball mill 4, and a feeding opening is provided on the box body at the feeding port of the ball mill 4, and the ball mill The discharge port of 4 is connected with a grading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com