Changeable flow channel structure of multifunctional disc type separator capable of changing multiple flow channels

A disc separator and multi-functional technology, applied in the field of fluid machinery, can solve the problems of difficult to clean and block, difficult to process and manufacture, easy to block, etc., to achieve convenient combination and replacement and installation, prevent blockage of flow channels, and easy to clean. Blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

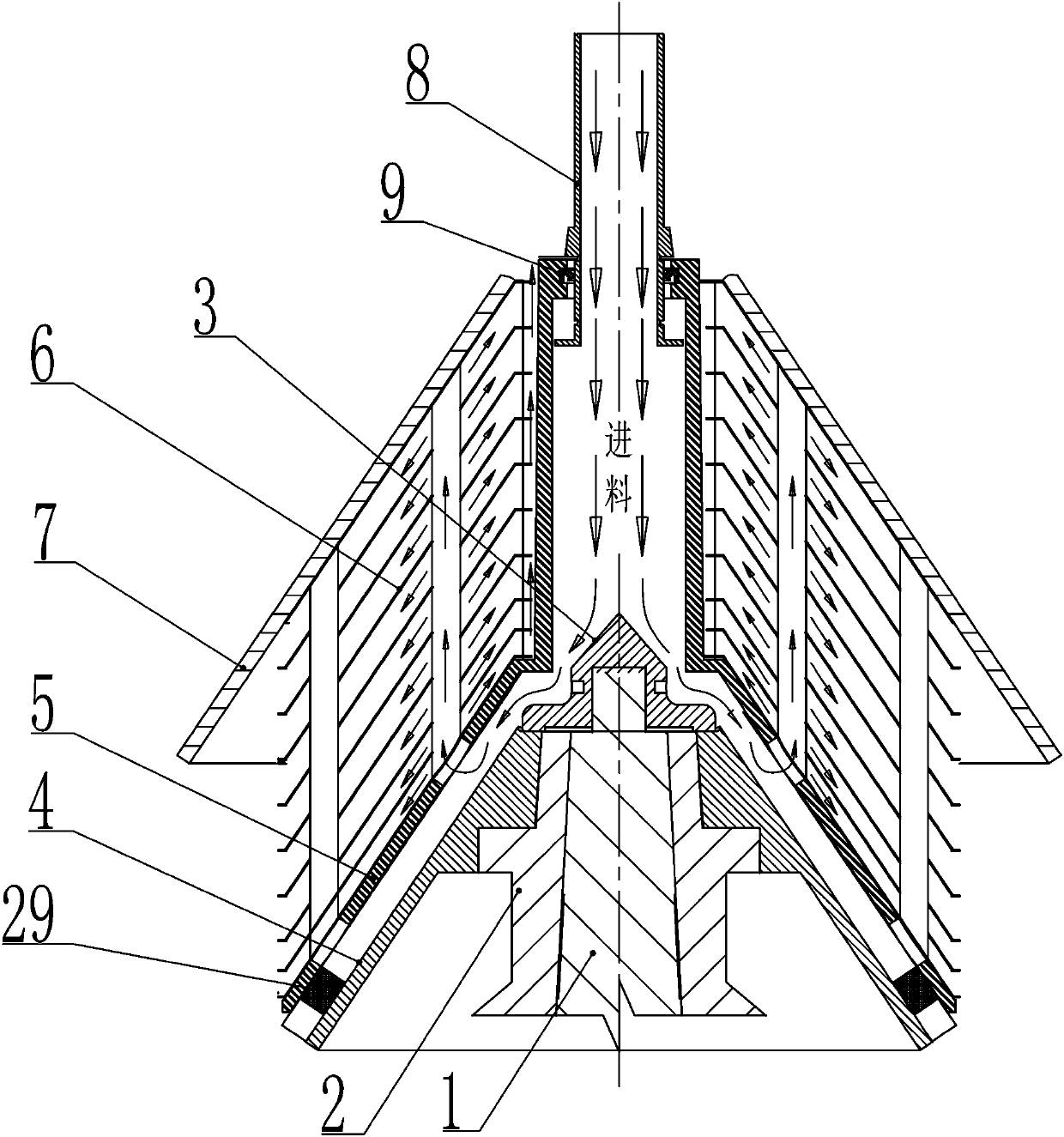

[0042] Such as figure 1 , Figure 5 , Figure 8 , Figure 10 , Figure 11 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 and Figure 18As shown, a variable channel structure of a multi-functional disc separator with multiple channels can be changed, including the drum lower body 2, locking screw cover 3, disc bracket base 4, disc bracket 5, disc 6, disc gland 7 and plug 29, the lock screw cover 3 is located at the upper end of the disc bracket base 4, the lock screw cover 3 has an internal thread, and is screwed on the outer surface of the top of the central shaft 1 through the internal thread. On the thread, the locking screw cover 3 is pressed on the disc bracket base 4, the outer peripheral surface of the joint between the drum lower body 2 and the disc bracket base 4 is a conical surface, and the disc bracket base 4 passes through the inner conical hole sleeve Pressed on the outer conical surface of the lower body 2 of the drum, the lower body 2...

Embodiment 2

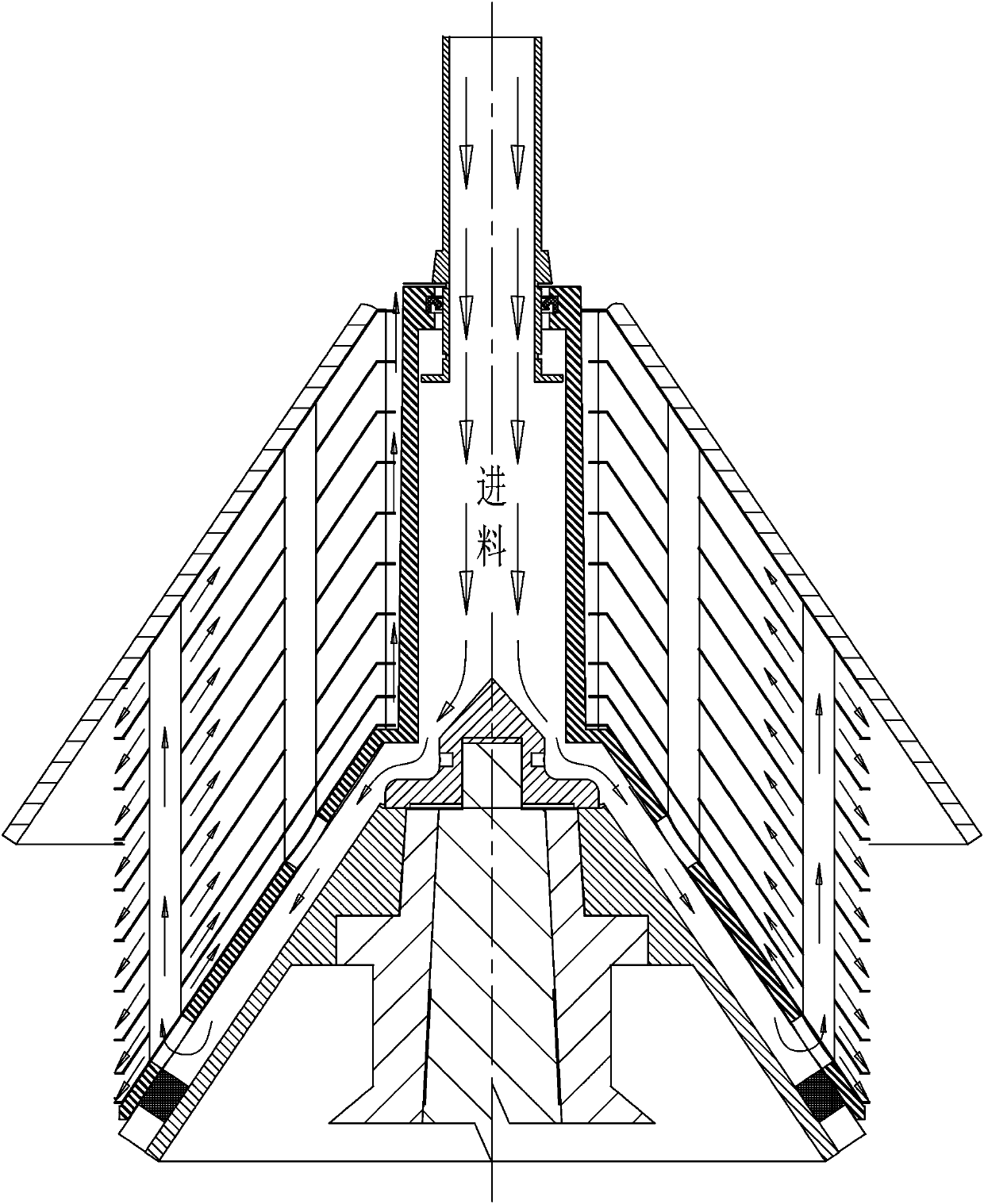

[0045] Such as figure 2 , Figure 4 , Figure 9 , Figure 10 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 and Figure 18 As shown, a variable channel structure of a multi-functional disc separator with multiple channels can be changed, including the drum lower body 2, locking screw cover 3, disc bracket base 4, disc bracket 5, disc 6, disc gland 7 and plug 29, the lock screw cover 3 is located at the upper end of the disc bracket base 4, the lock screw cover 3 has an internal thread, and is screwed on the outer surface of the top of the central shaft 1 through the internal thread. On the thread, the locking screw cover 3 is pressed on the disc bracket base 4, the outer peripheral surface of the joint between the drum lower body 2 and the disc bracket base 4 is a conical surface, and the disc bracket base 4 passes through the inner conical hole sleeve Pressed on the outer conical surface of the lower body 2 of the drum, the lower body...

Embodiment 3

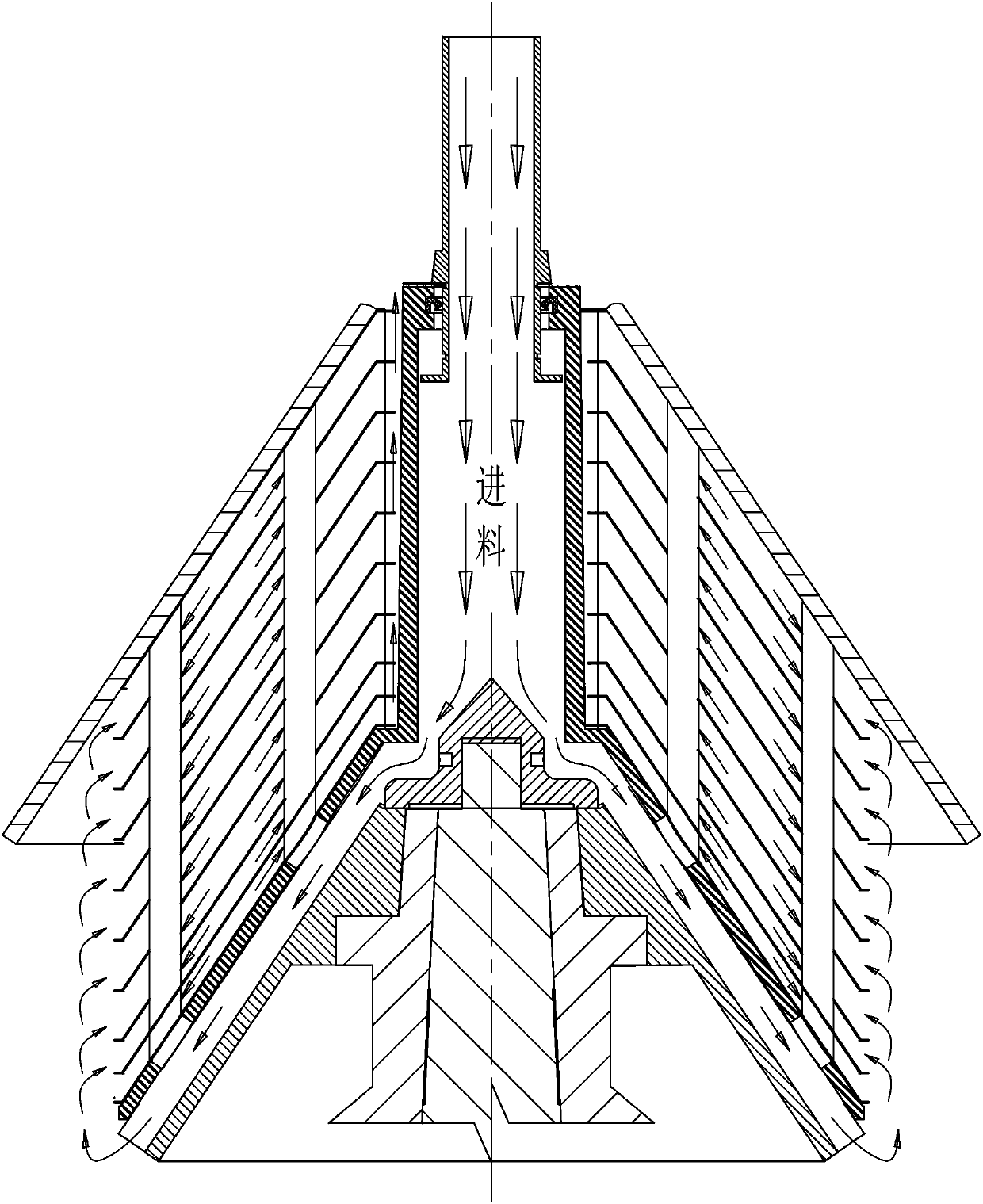

[0048] Such as image 3 , Figure 6 , Figure 7 , Figure 10 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 and Figure 18 As shown, a variable channel structure of a multi-functional disc separator with multiple channels can be changed, including the drum lower body 2, locking screw cover 3, disc bracket base 4, disc bracket 5, disc 6, disc gland 7 and plug 29, the lock screw cover 3 is located at the upper end of the disc bracket base 4, the lock screw cover 3 has an internal thread, and is screwed on the outer surface of the top of the central shaft 1 through the internal thread. On the thread, the locking screw cover 3 is pressed on the disc bracket base 4, the outer peripheral surface of the joint between the drum lower body 2 and the disc bracket base 4 is a conical surface, and the disc bracket base 4 passes through the inner conical hole sleeve Pressed on the outer conical surface of the lower body 2 of the drum, the lower body 2 of the drum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com