A preparation method of 3D-graphene material using biomass resources as carbon source

A technology of biomass resources and graphene, applied in the field of preparation of 3D-graphene materials, can solve the problems of high production cost, complicated operation, and no patent publications have been found, and achieves low cost, good biocompatibility and good biocompatibility. The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

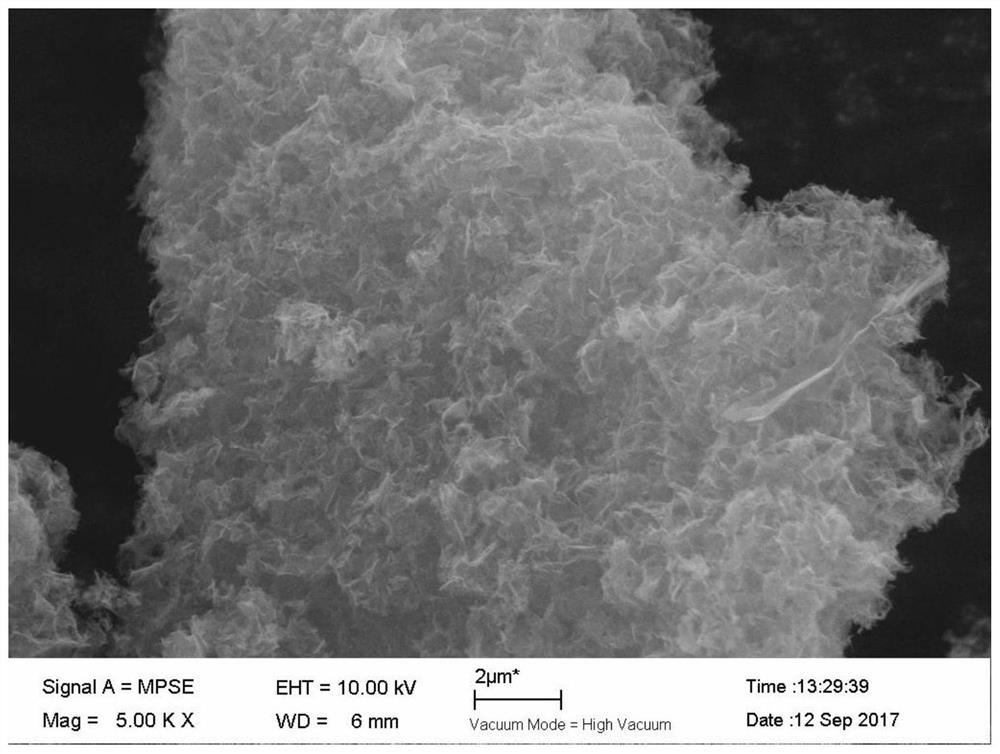

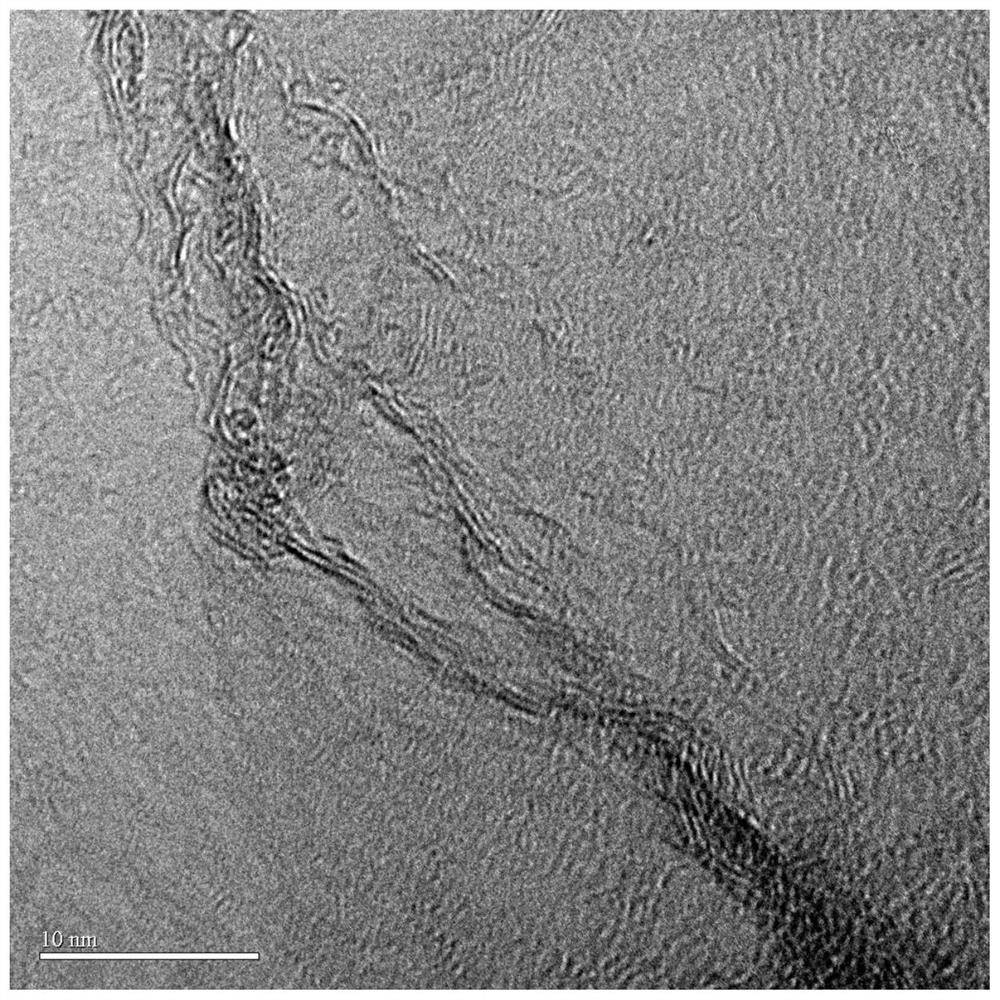

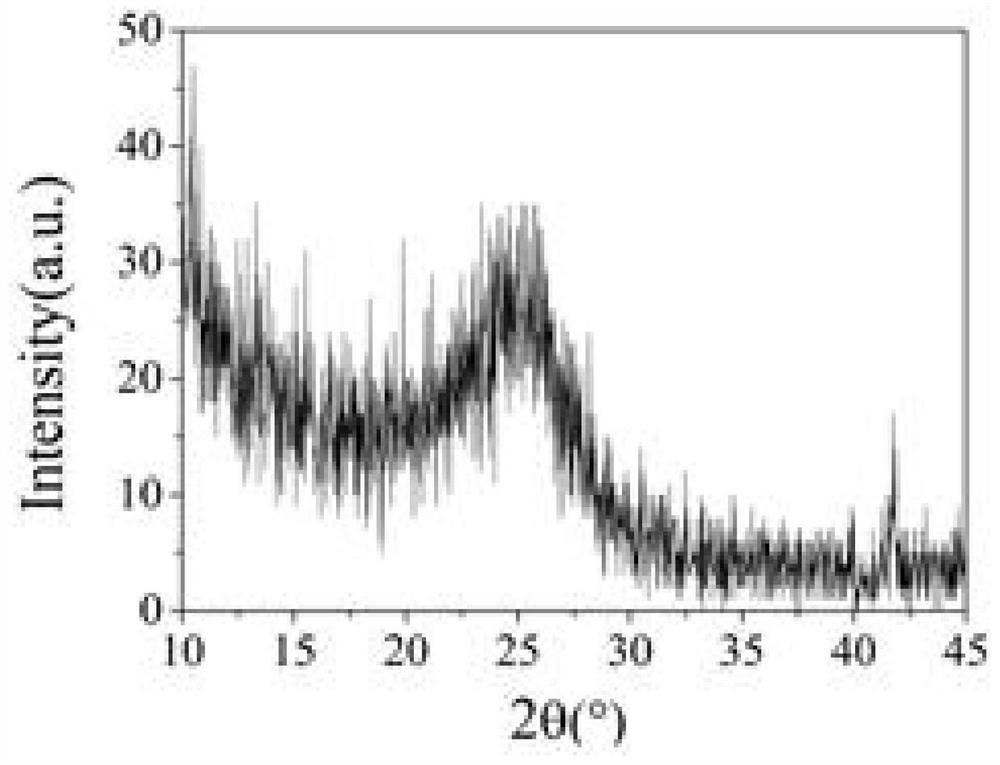

[0033] A preparation method of 3D-graphene material using protein as carbon source, the steps are as follows:

[0034] (1) Dissolve bovine serum albumin in the aqueous solution, stir at 20 °C to dissolve it, add sodium sulfate, continue to stir until it forms a uniform solution, and titrate the above-mentioned liquid into ethanol with a syringe pump (titration speed 200ul / min) to obtain The white solid is dried in a vacuum drying oven at 80°C to 120°C for 4 to 12 hours to obtain a mixture of bovine serum albumin and salt;

[0035] Wherein, the mass ratio of the bovine serum albumin and salt is 1:3;

[0036] (2) Put the mixture of protein and salt in step (1) into a tube furnace for carbonization, disperse the carbonized sample in water, and filter to obtain a black solid, that is, a 3D-graphene material.

[0037] The heating program was as follows: from room temperature to 300°C at 2°C / min and maintained for 2 hours, and then heated to 500°C at 3°C / min and maintained for 1 ho...

Embodiment 2

[0039] A preparation method of 3D-graphene material using glycine as carbon source, the steps are as follows:

[0040] (1) Dissolve glycine in the aqueous solution, after stirring at 20 ° C to dissolve it, add potassium chloride, continue to stir until it forms a uniform solution, titrate the above-mentioned liquid into isopropanol with a syringe pump (titration speed 300ul / min), A white solid is obtained, which is dried in a vacuum drying oven at 80°C to 120°C for 4 to 12 hours to obtain a mixture of glycine and salt;

[0041] Wherein, the mass ratio of described glycine and salt is 1:5;

[0042] (2) Put the mixture of step (1) glycine and salt into a tube furnace for carbonization, disperse the carbonized sample in water, and filter to obtain a black solid, that is, a 3D-graphene material is obtained.

[0043] The heating program is as follows: from room temperature to 200°C at 3°C / min and maintained for 1-2 hours, and then heated to 600°C at 1°C / min and maintained for 1-2 ...

Embodiment 3

[0045] A preparation method of 3D-graphene material using glutamic acid as carbon source, the steps are as follows:

[0046] (1) Dissolve glutamic acid in the aqueous solution, stir at normal temperature (25 ° C) to dissolve it, add copper sulfate, continue to stir until it forms a uniform solution, and titrate the above-mentioned liquid into isopropanol with a syringe pump (titration speed 500ul) / min) to obtain a white solid, which is dried in a vacuum drying oven at 80°C to 120°C for 4 to 12 hours to obtain a mixture of glutamic acid and salt;

[0047] Wherein, the mass ratio of described glutamic acid and salt is 1:8;

[0048] (2) Put the mixture of step (1) glutamic acid and salt into a tube furnace for carbonization, disperse the carbonized sample in water, and filter to obtain a black solid, that is, a 3D-graphene material is obtained.

[0049] The heating program is as follows: from room temperature to 350°C at 2°C / min and maintained for 1-2 hours, and then heated to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com