Intelligent carbon fiber thermoplastic composite structure and manufacturing method thereof

A composite material and intelligent structure technology, applied in additive manufacturing, processing and manufacturing, manufacturing tools, etc., can solve the problem of lack of online or in-situ repair methods, achieve online in-situ self-repair of damage, improve strength, and reduce damage repair. The effect of time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

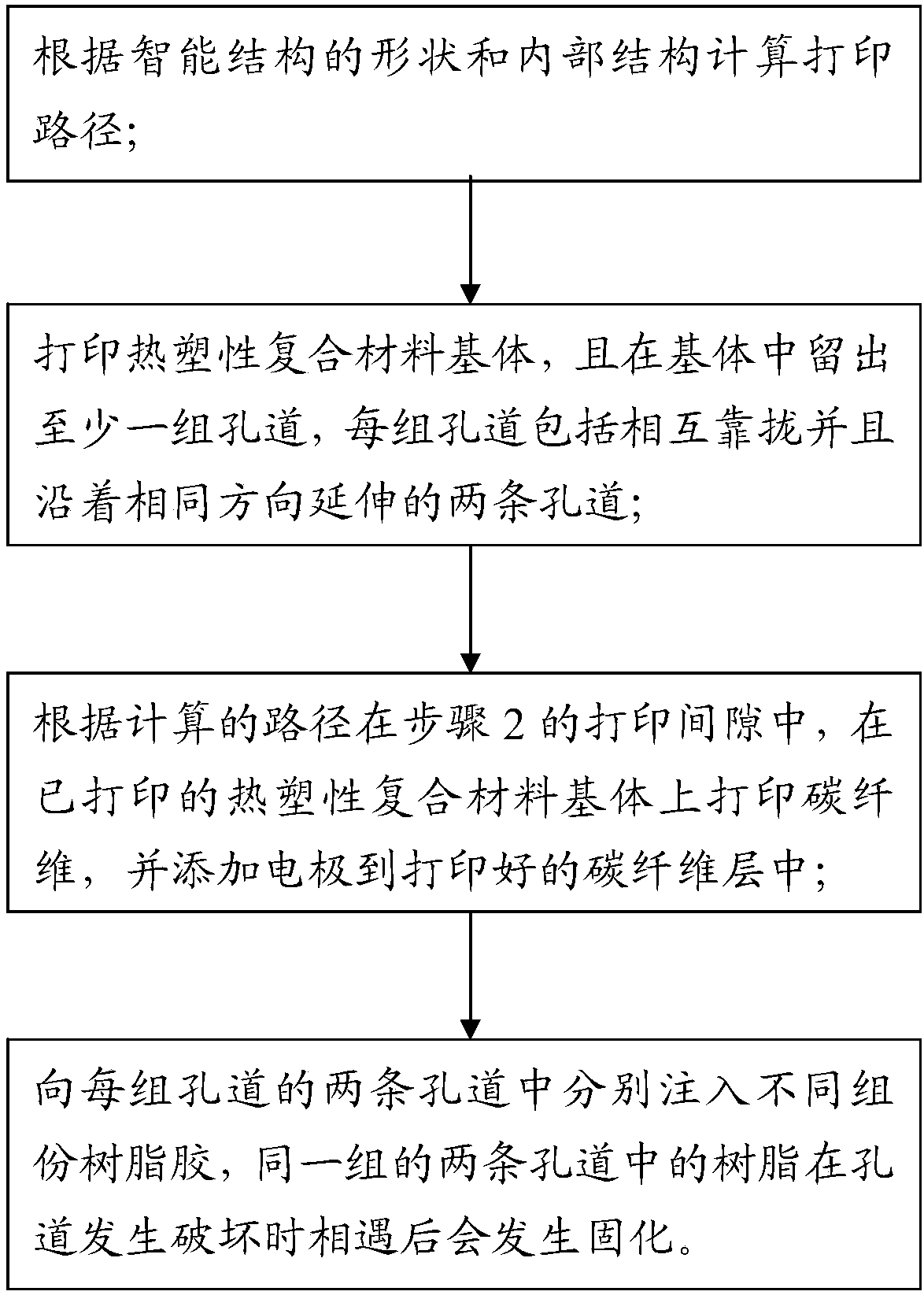

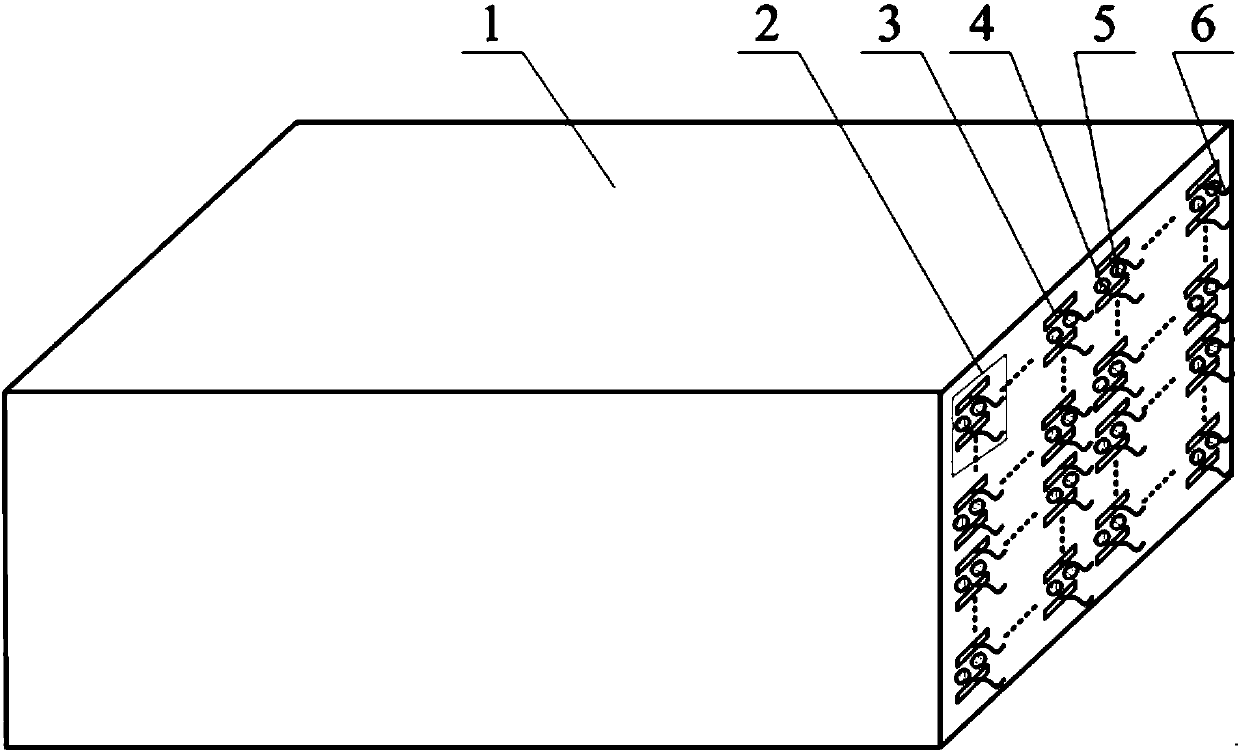

[0032] Such as figure 1 As shown, the manufacturing method of the carbon fiber thermoplastic composite smart structure of this embodiment includes the following steps:

[0033] Step 1: Calculate the printing path according to the shape and internal structure of the smart structure;

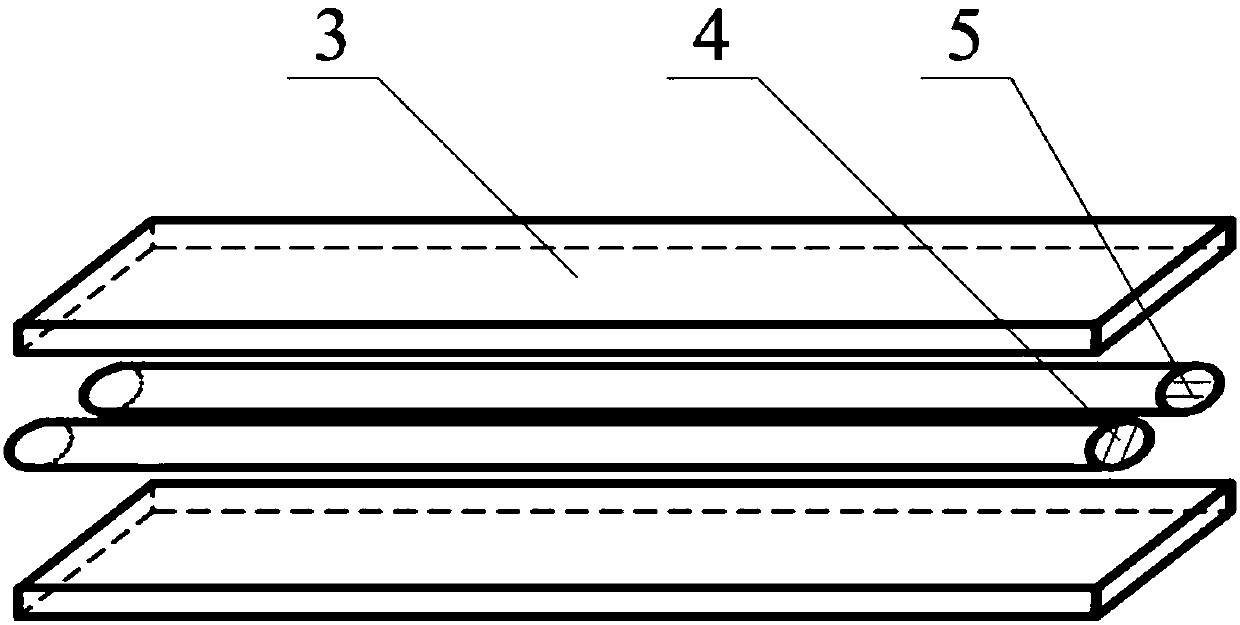

[0034] Step 2: printing the thermoplastic composite material matrix, and leaving multiple groups of channels in the matrix, each group of channels includes two channels 4 and 5 that are close to each other and extend in the same direction;

[0035] Step 3: According to the calculated path, in the printing gap of step 2, print carbon fiber on the printed thermoplastic composite material substrate, and add electrodes to the printed carbon fiber layer, a set of channels 4 and 5, carbon fiber 3 and electrodes Form a minimum unit module 2;

[0036] Step 4: After printing in step 2, inject different components of resin glue into the two channels of each group of channels, and the resin in the two chan...

Embodiment 2

[0043] In this embodiment, other steps are the same as in Embodiment 1 except that the channel sealing method is different.

[0044] The manufacturing method of the carbon fiber thermoplastic composite intelligent structure of the present embodiment comprises the following steps:

[0045] Step 1: Calculate the printing path according to the shape and internal structure of the smart structure;

[0046] Step 2: printing the thermoplastic composite material matrix, and leaving multiple groups of channels in the matrix, each group of channels includes two channels 4 and 5 that are close to each other and extend in the same direction;

[0047] Step 3: According to the calculated path, in the printing gap of step 2, print carbon fiber on the printed thermoplastic composite material substrate, and add electrodes to the printed carbon fiber layer, a set of channels 4 and 5, carbon fiber 3 and electrodes Form a minimum unit module 2;

[0048] Step 4: After printing the channels in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com