A Multi-mode Hybrid Coupling Drive System

A hybrid and coupling drive technology, applied in the field of vehicle power transmission, can solve the problems of many gear logarithmic synchronizers, large transmission loss, difficult engine, etc., to improve shift comfort, improve power performance, and facilitate space layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

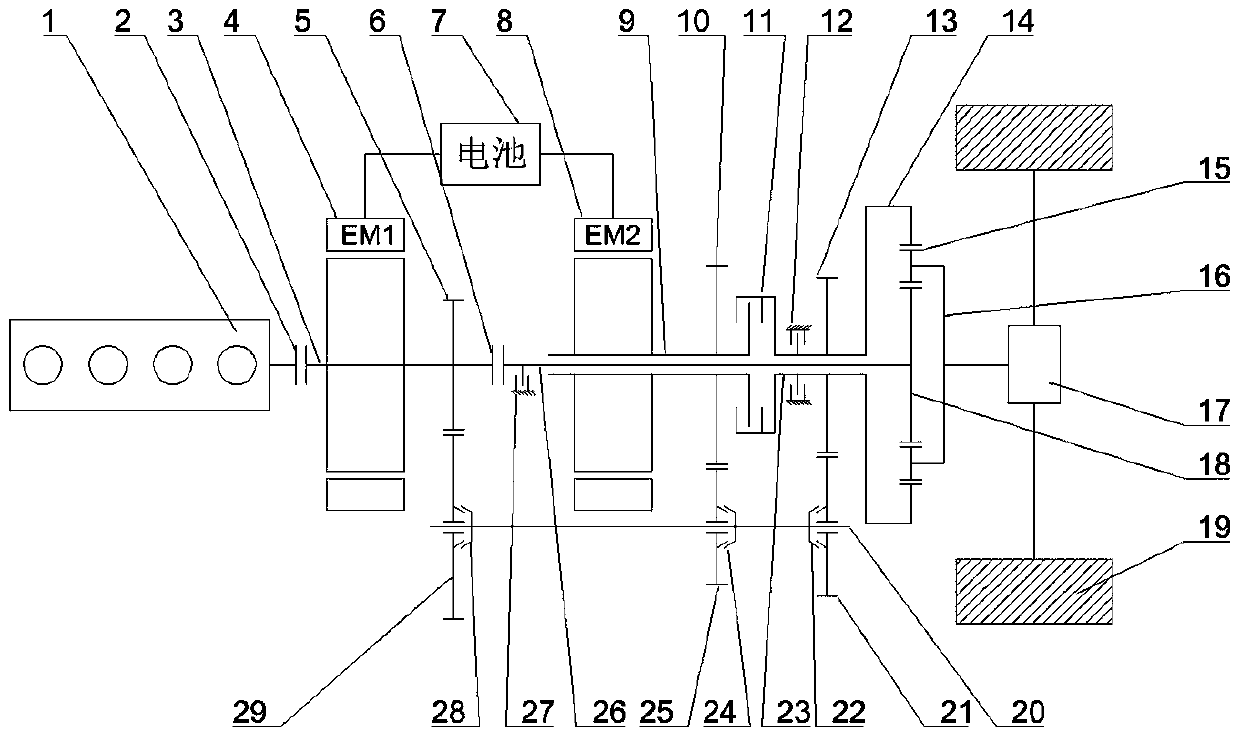

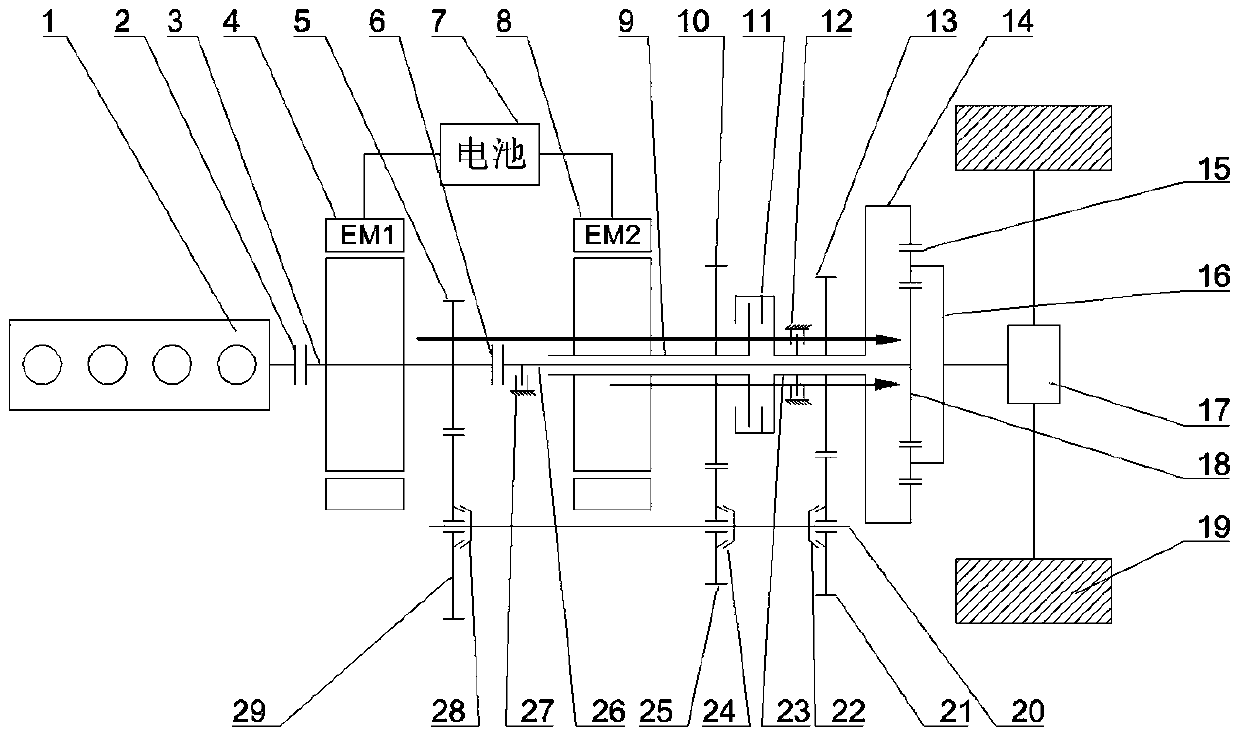

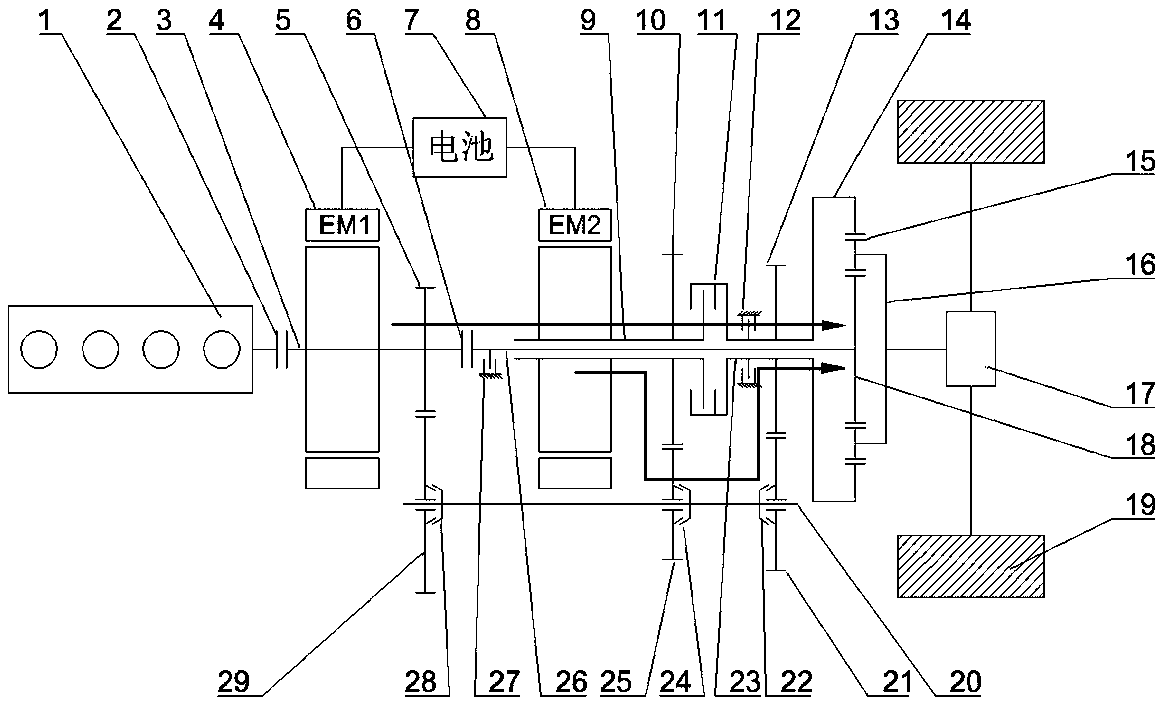

[0036] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0037] see figure 1 , a multi-mode hybrid coupling drive system includes an engine 1, a first motor 4, a second motor 8, a differential 17 and a transmission mechanism. Both the first motor 4 and the second motor 8 are permanent magnet synchronous motors.

[0038] The transmission mechanism includes a dual-clutch transmission mechanism and a single-row planetary gear mechanism.

[0039] The dual clutch transmission mechanism includes an engine power input shaft 3 , an input tube shaft 9 , an engine power output shaft 26 , an output tube shaft 23 and an intermediate shaft 20 . The input tube shaft 9 and the output tube shaft 23 are loosely sleeved on the engine power output shaft 26 in sequence, and the output end of the input tube shaft 9 and the input end of the output tube shaft 23 are connected through the third clutch 11 .

[0040] The si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com