Composite admixture for improving durability of common concrete by improving gradation

A composite admixture and ordinary concrete technology, applied in the field of building materials, can solve the problems of not considering the durability of admixture concrete, lack of concrete durability, etc., and achieve the effects of good market prospects, improved durability, and wide use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

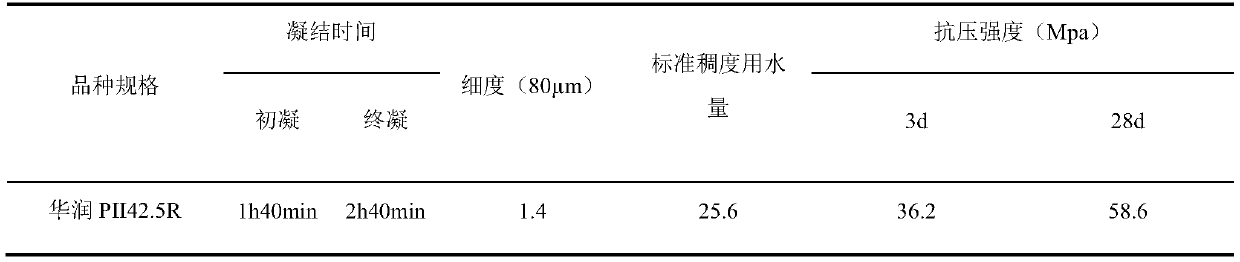

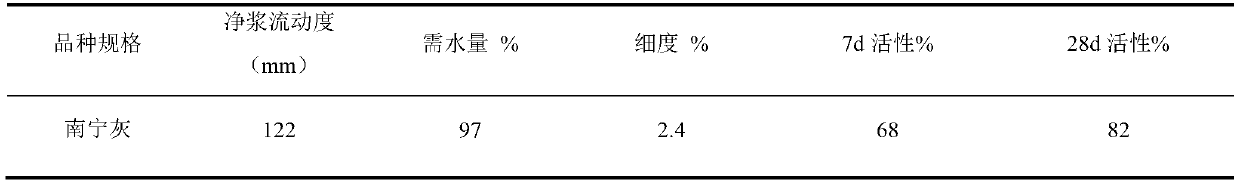

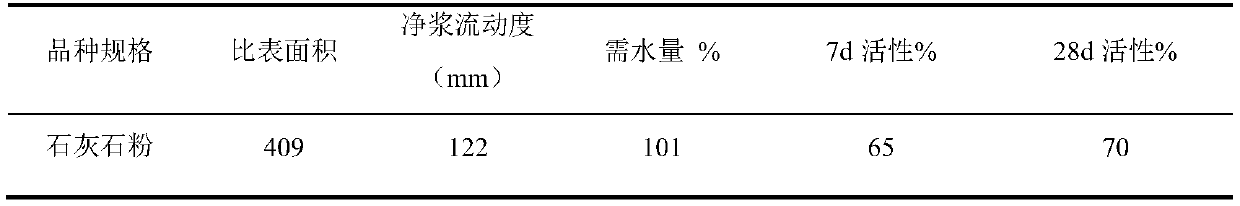

[0045] (1) Prepare the concrete raw materials of the following raw materials for use:

[0046] (2) Production grading: Sieve the fly ash according to 0-10um, 10-20um, 20-30um, 30-45um, 45-60um, collect after sieving for use; ball mill the limestone powder, and then Sieve 0-20um, 20-30um, 30-45um, collect after sieving for use; ball mill the slag powder, then sieve according to 0-15um, 15-30um, 30-45um, collect after sieving Use; ball mill the ceramic powder, then sieve according to 0-20um, 20-30um, 30-45um, collect after sieving for use; ball mill the volcanic ash, and then sieve according to 0-20um, 20-30um, 30-45um , 45-120um for sieving, and collect after sieving for use;

[0047] (3) Preparation of admixture: mechanically mix 1500g of fly ash, 2000g of limestone powder, 500g of slag powder, 500g of ceramic powder, 500g of pozzolan, and 50g of silica fume, wherein the gradation of fly ash is 0-10um 30%, 10-20um accounts for 35%, 20-30um accounts for 25%, 30-45um accounts ...

preparation Embodiment 2

[0049] This example only describes the differences from Example 1, and the gradation of the admixture in this preparation example is different.

[0050] (3) Preparation of admixture: 1500g of fly ash, 2000g of limestone powder, 500g of slag powder, 500g of ceramic powder, 500g of pozzolan, and 50g of silica fume are mechanically mixed, wherein, wherein, the gradation of fly ash is 0-10um Accounted for 40%, 10-20um accounted for 25%, 20-30um accounted for 20%, 30-45um accounted for 10%, 45-60um accounted for 5%; the gradation of limestone powder is 0-20um accounted for 60% , 20-30um accounted for 30%, 30-45um accounted for 10%; the gradation of slag powder was 0-15um accounted for 35%, 15-30um accounted for 45%, 30-45um accounted for 20%; ceramic powder The gradation of 0-20um accounts for 40%, 20-30um accounts for 40%, 30-45um accounts for 20%, the gradation of volcanic ash is 0-20um accounts for 20%, 20-30um accounts for 28%, 30- 45um accounts for 27%, and 45-120um accounts ...

Embodiment 3

[0052] This example only describes the differences from Example 1, and the gradation of the admixture in this preparation example is different.

[0053] (3) Preparation of admixture: mechanically mix 1500g of fly ash, 2000g of limestone powder, 500g of slag powder, 500g of ceramic powder, 500g of pozzolan, and 50g of silica fume, wherein the gradation of fly ash is 0-10um 25%, 10-20um accounts for 35%, 20-30um accounts for 25%, 30-45um accounts for 10%, 45-60um accounts for 5%; the gradation of limestone powder is 0-20um accounts for 65%, 20 -30um accounted for 28%, 30-45um accounted for 7%; the gradation of slag powder was 0-15um accounted for 30%, 15-30um accounted for 50%, 30-45um accounted for 20%; the gradation of ceramic powder 0-20um accounts for 40%, 20-30um accounts for 40%, 30-45um accounts for 20%, the gradation of volcanic ash is 0-20um accounts for 20%, 20-30um accounts for 30%, 30-45um accounts for 20% 25%, 45-120um accounted for 25%, homogenized after mixing, y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com